Check out the latest updates to the Flyntlok Equipment Dealer Management System.

Between today, May 5th, 2021, and May 12th, 2021, we want to reduce unnecessary mouse clicks within the application. Submit a support ticket with your idea to reduce clicks. As a team, we will determine the most impactful request, implement the changes, and reward that user with a $25 visa gift card!

Starting today, we will be making weekly updates to reduce the use of your mouse on the Point of Sale. Be on the lookout for new hotkeys and shortcuts!

There is now a quantity box to the right of the item searcher on the point of sale.

To use this, click into the item searcher and search your part number. When you've found the part you want, and it is highlighted, hit the Tab button. This will add the item into the item search box and move your cursor into the Qty box. From here, you can input the quantity by using the up/down arrows or entering the number you wish to sell. Once quantity is added, hit the Enter button on your keyboard to add the part at that quantity to the sale. You will also notice that your cursor defaults back into the item searcher box after the part is added to the sale. This allows you to keep searching and adding parts without lifting your hands off the keyboard!

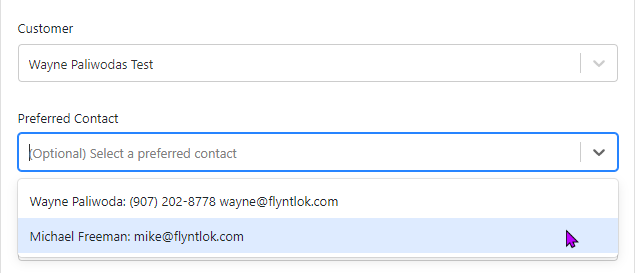

We understand with large commercial customer accounts, there are many points of contact you are interacting with on a day-to-day basis. You can now designate a preferred contact when creating a work order.

On the work order dashboard, you will see the preferred contact listed under the Basic Information section. Clicking the View all contacts just below the preferred contact information will bring up the form to edit, delete, and add new contacts.

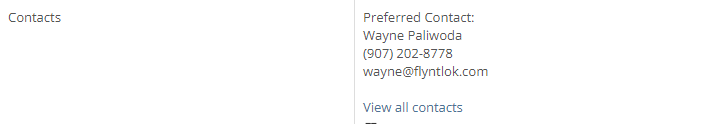

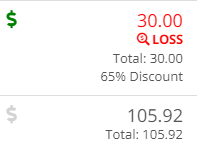

We ran into an issue where a colorblind user was not able to denote that an item was being sold below cost. Now, when an inventory item or machine is being sold below cost, we show an icon with Loss below the item's price. This is also useful when you are applying discounts to an invoice.

Previously, we were not obtaining the cost and time of all linked work orders. We refactored the costing and time information of the work orders to include all sub-work order costs, which allows us to add more information:

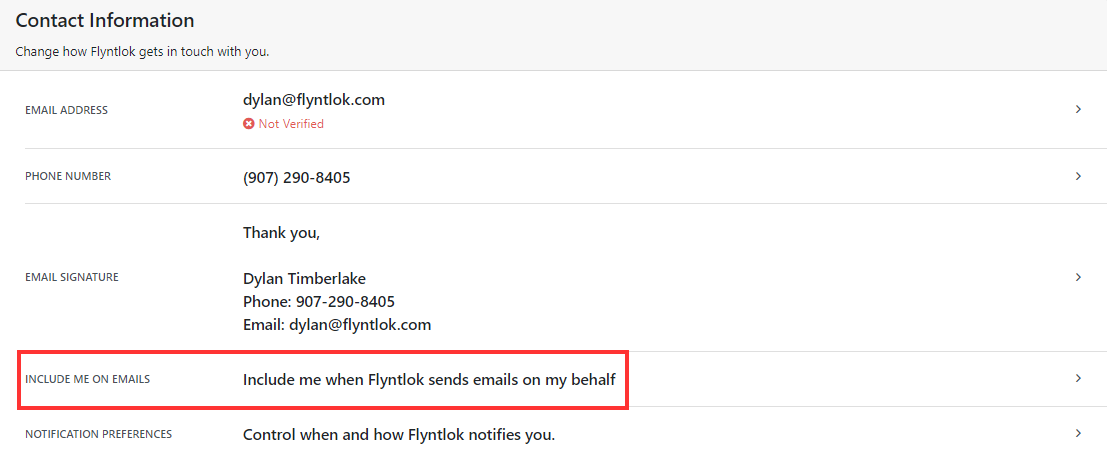

This setting was still working but was inadvertently removed when we updated this page.

When editing your user preferences, select View Your Profile, then under the Contact Information section, you will find the Include me on Emails field.

We have added validation to the Customer PO field on the Point of Sale. The limit was always 45 characters, but we did not prevent you from entering more than 45 characters.

We were not preventing you from submitting bills without the appropriate data. Now, to post as a bill, there must be an accounts payable (A/P) account set, and that A/P line must have a vendor set.

We made changes to the algorithm used to calculate the margin on the point of sale. This now accurately accounts for average cost when showing the margin. Please let us know if you run into any weird margins, but it should be more accurate now!

We have run into issues with users unknowingly overwriting data that another user set. When editing a machine purchase order's date ordered, date expected, or date invoiced, we now will not update those dates on the machines associated with the purchase order.

April 28th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

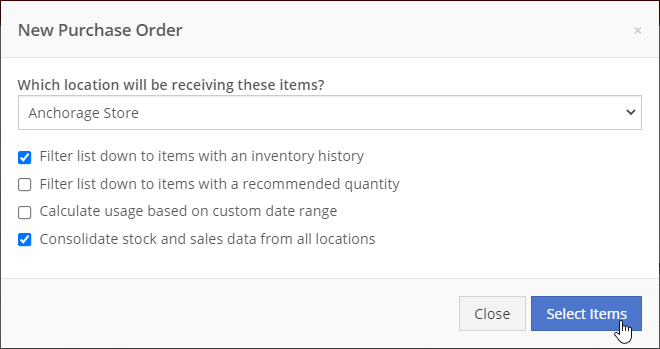

When creating a stock order, you now have the option to consolidate all of your sales data across your locations. When this option is selected, we will sum up all of the stocking levels and historical sales per item. The PO will still be for an individual location.

We will now default price updates with the current margin of the price by default. This should save you some time and thought when you update the cost of a part if your margins are not changing!

From a machine dashboard, you can now print a report that includes the specifications of the machine and the service history of that machine. To print this report, click the "Customer" in the basic information section.

We will now attempt to assign a class to items that do not have a class assigned to them based on the other items on the invoice when posting to QuickBooks Online.

We have updated our error images. We hope you enjoy them as much as we do!

We fixed an error with calculating the average cost of a part on the EOD report.

April 14th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

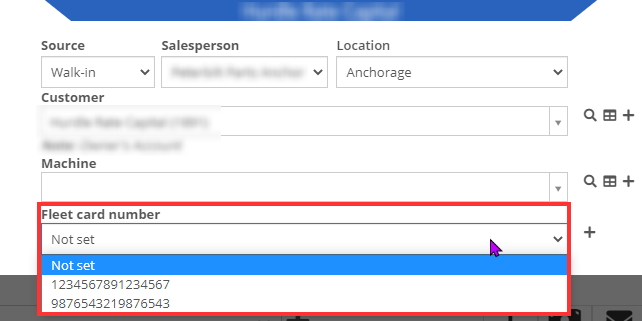

For PACCAR Fleet customers, you can now associate a fleet card with a sales order. By assigning a fleet card, we will verify the card and update the item pricing for that fleet customer.

For PACCAR dealerships, you will now see the Fleet Card Number box on invoices. After assigning a customer, there will be a list of fleet card numbers to select from for the customer.

If the customer doesn't have a fleet card or the fleet card that they are trying to use doesn't exist, you can click the '+' to the right of the card selector box and add a new card for the customer.

Once the invoice is completed, you will use the Account payment type and close out the invoice.

NOTE: Flyntlok recommends that you add the fleet card to the invoice after adding all parts. This method will go out and check the pricing for all the parts on the invoice at once, instead of checking the price every time an item is added to the sales order.

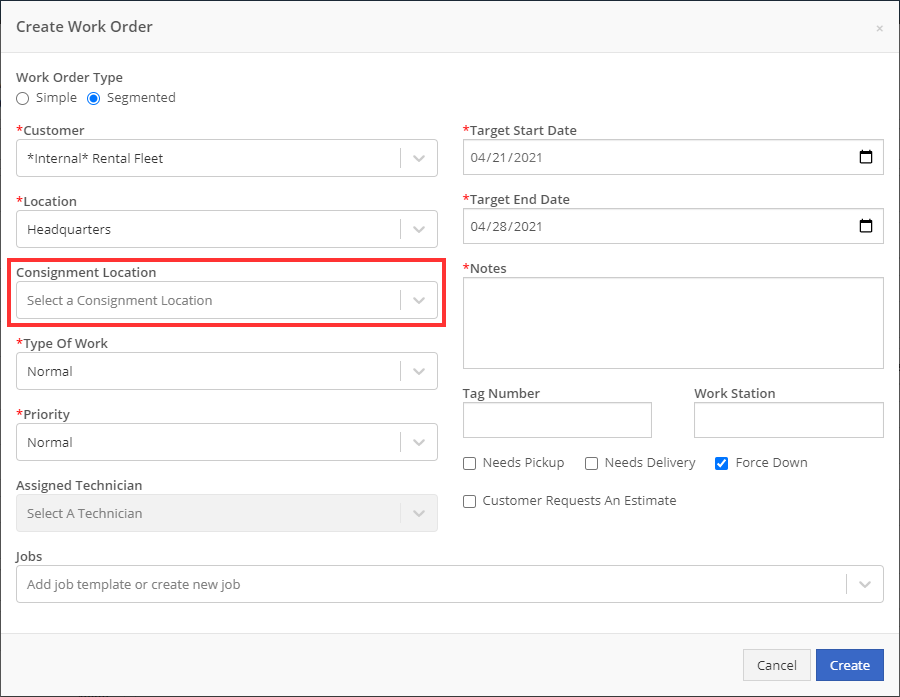

When creating a work order, you can now assign a consignment location to that work order. What this will do is first pull consignment quantity for any internal parts orders before pulling the store location's QOH. If there is not enough quantity at the consignment location to fulfill the order, we will then pull from the store's QOH, or prompt the part to be ordered if there is not enough at the store.

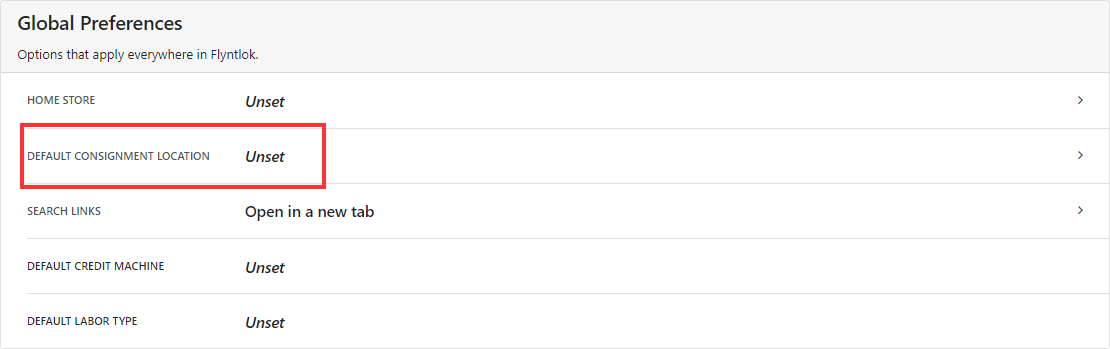

When editing your user profile, you can now set a default consignment location. This will be the default consignment location when the user is creating a work order.

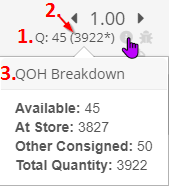

When adding a consigned item to a sales order, we have changed the quantity data that shows on the sales order. When on an internal parts order that has a consignment location assigned:

When selling consigned items that are not on an internal parts order linked to a consignment location:

When searching for items on Sparks, we were not showing all the items that vendors were supplying us on the price files.

We fixed an issue that forced users to refresh their browser after taking a credit card payment.

When receiving items, the calculator will now account for the purchasing units of the item.

You can now set the received cost of an item down to the 4th decimal place.

April 14th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

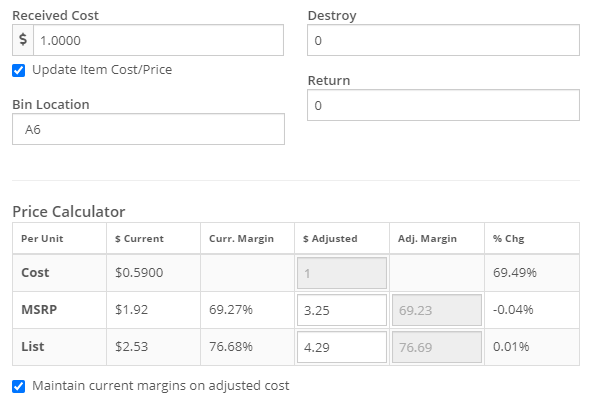

When receiving items from a purchase order, you will now be able to update or set the list price and MSRP of the item. You will now see a check box below the cost box. Clicking this check box will bring up the price calculator that will assist you in choosing what your list price and MSRP should be by calculating on-the-fly margins.

You will be able to compare your past margins to the new margins to help find the best price point for the item.

When editing a work order, you can now edit the check-in time of the machine.

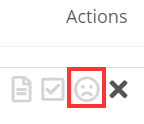

From a sales order, you will be able to report a lost sale for an item. You will see a sad face under the actions column of the sales order for each item. Clicking this will take you to a prefilled loss report for that item.

When a Sparks customer submits a sale, Flyntlok will pick either the Sparks customer's assigned salesperson, the salesperson assigned to their account in Flyntlok, or the Sparks Champion set for the company to be set as the salesperson of the sales order.

When viewing a machine move, we will now show the customer associated with that move in the Move Info section.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

When an internal parts order quote has been rejected, we will indicate that rejection on the work order dashboard.

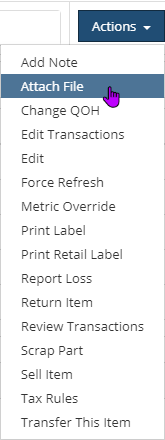

There is now an option in the actions dropdown of the item dashboard to add a file attachment.

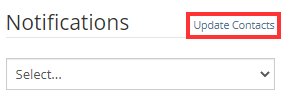

When a customer is putting payment on their Sparks order, they can edit or add a contact for the sale.

This will bring up a form that will allow customers to edit an existing contact or add a new contact for the customer.

There can now be one user configured at a company to be the Sparks Champion. This user will receive the following notifications:

We now show the customer unit number associated with a machine when assigning a machine to a sales order.

When receiving machines on a machine purchase order, we have added the ability to input invoice date and invoice number.

When resetting your password, we now accept the email linked to your account as verification to reset your password.

We have resolved an issue that was blocking most common parts from being added to sales orders.

The formatting of the machine condition report on a rental PDF has been fixed.

March 31st, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

Flyntlok will be closed on Friday, April 2nd, in observance of Good Friday.

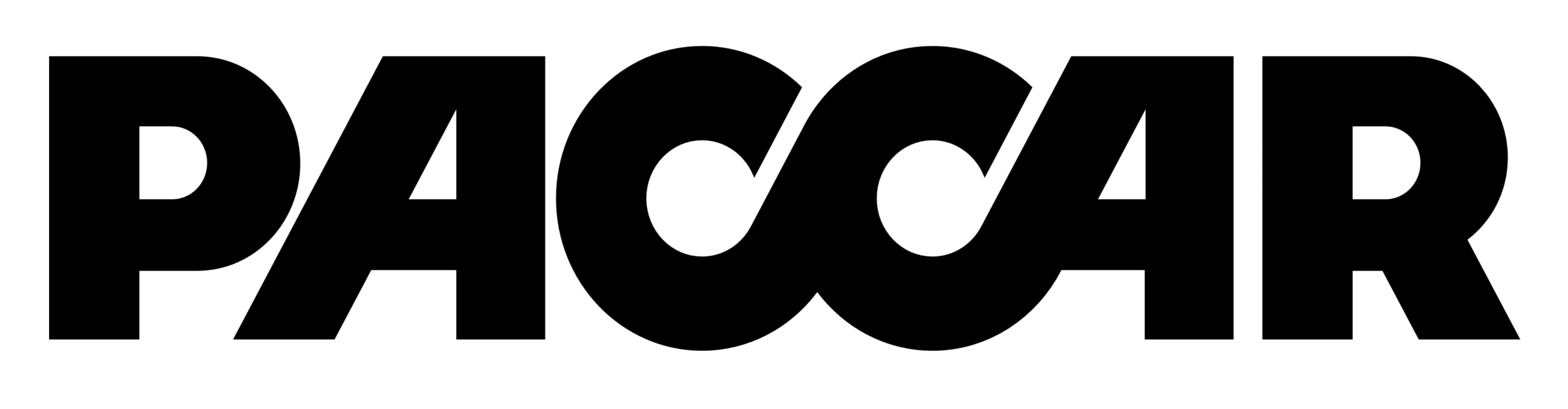

We have released a new feature that allows you to submit warranty claims from Flyntlok to the PACCAR eportal. From a Flyntlok work order, you will be able to open up a warranty claim that is prefilled with work order data!

To get to the PACCAR form, your location will need to be configured by Flyntlok to allow PACCAR submissions. Then you will want to make sure that the work order is set to type Warranty. When those two conditions are met, you will see a Start Warranty Claim in the work order dashboard's actions drop-down.

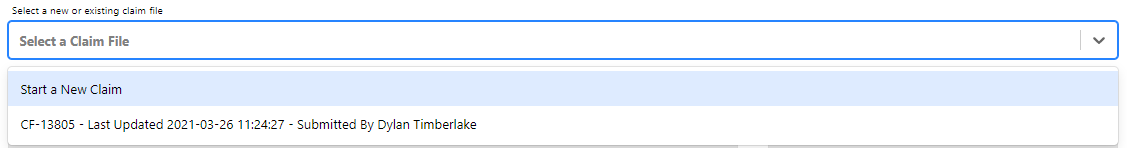

If it is the first submission from the work order, you will need to fill out the Claim & Vehicle Information section and then save the claim. This will generate the CF (Claim File) in the PACCAR eportal.

Once this is successfully saved, you will be able to select the jobs from the work order that you wish to submit a RO (Repair Order) for. This allows you to submit multiple jobs for one claim file or create multiple claim files from one work order.

When on a work order that you have already submitted a claim for, you will be able to go back to those previously submitted claims via the claim file selector or create a new claim.

If you have more questions, please reach out to Flyntlok. We will be able to provide a more in-depth Q/A about the warranty form and submission.

We have added more granular permissions around editing a machine. Below are the 7 new domains for machine permissions and the sections of a machine they control:

Flyntlok now supports the uploading of .EIF type files!

We enhanced the safety measures in place to prevent electronic POs from being submitted more than once.

We also now don't submit the core item from a PO to Epiroc or PACCAR. The core item will remain on the Flyntlok PO to be received.

We apologize for the headaches in the past week that were caused by slow customer searching. We have made some changes to make customer search lightning fast!

We released this feature a few weeks ago and are pulling it back to reassess. We will have a better method for this in the future.

March 24th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

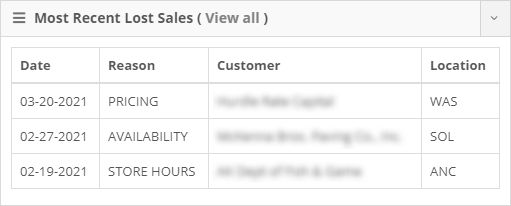

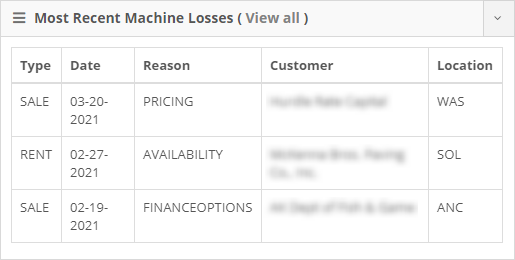

On the lower left of the item and machine dashboard, you will find a reported losses widget. We will show the 10 most recent loss reports for the item or machine.

Item Dashboard Widget:

Machine Dashboard Widget:

You will also be able to click the View All button to all losses reported for the item or machine.

When you are transferring an item to be used on a sales order, but not transferring enough to entirely fulfill the order, we now create a purchase plan for the remaining items. When the combination of the purchase and transfer is received, you will be able to fulfill the order and any excess received parts will go into the QOH.

We can now tailor your sparks portal closer to your business workflow. For example, if you do not do rentals at your business, we can disable that feature from Sparks. This also applies to showing work orders and machines.

We updated the common parts button on Sparks to show common parts for the customer, and if you have a machine selected, common parts for the machine associated with the sale.

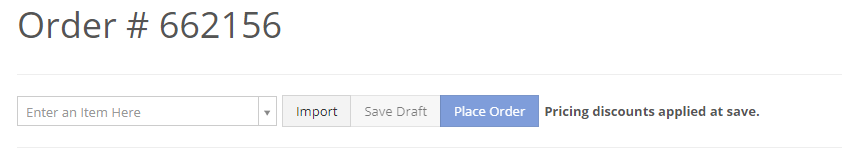

We made sure to let your customers know that they must save their drafts to see their custom pricing discounts.

We made the modal when accepting payments on Sparks a bit more contextual. For example, if one of your customers is charging to their account, the modal previously said Enter Card. It now says Charge instead.

We have added the sales order number to My Orders view. The view now also sorts in the order the sales were created.

When merging a special order purchase plan into a stock order, if there is a core associated with the item, we will merge the core purchase onto the stock order as well.

March 10th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

We understand that some of your markets may be pretty competitive. To help, we now let you hide part numbers on quotes. This is a location-based setting that can be adjusted under your location settings. You must have administrative rights to Flyntlok to adjust.

We have changed the link on issue submission from our old FAQ site to the new one. You can check out the new FAQ site here!

You can now use W? to search for work orders. Here is a list of all the things that we will attempt to match with your search input:

We have updated the Flyntlok keyed-in cards system so that we are up to date with the most recent Gravity Payments standards. If you ran into any issues in the past week, it would have been due to this change not being implemented yet.

You can now sort your to-be-ordered board by items that can be merged into in-process purchases. If you are not familiar with this feature, it lets you take special order purchase requests and allocate them to an in-process stock order request.

You can now search for customers with the phone numbers of contacts associated with the customer. Before, you could only search for the customer record of the company and contact phone. We will now compare the phone number put into the customer contacts' mobile phone records.

Printing an item label will now show a shortened version of the item's description.

We will now send the line description through to QuickBooks even if the machine ID is not set on the line.

When adding the tracking number to the internal notes of a sales order, we will only show the tracking reminder notification once.

March 10th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System

Flyntlok is excited to announce a new integration with the Decisiv SRM platform. This is a service relationship management platform that is used to create and manage end-to-end service event workflow. Like Flyntlok, Decisiv is a cloud-based platform giving you access from any computer or mobile device.

Service management automates the asset maintenance and repair process from check-in to check-out. Repair details are included in each service event case that is created, including commentary from technicians, service estimating, and collaboration history.

Users can receive in-context communication at the point of service, curated and delivered based on their specific function and role. Customized alerts are provided based on preferences and criteria related to service events, from breakdown cases to estimated completion time, to downtime threshold notifications, and more.

Create electronic estimates and send them to the machine owner for approval. The machine owner is able to approve estimates from dealers or vendors; including line item approvals. Asset owners can accept, defer, or decline individual line items on the estimate.

Decisiv allows service providers to perform the vehicle check-in process from a mobile device. Users of the mobile app are able to easily find or add a vehicle into the SRM system, see in-progress service events, update mileage or engine hours, including a complaint, add and conduct an inspection, add operations and parts, attach pictures, and assign the service event to another user (eg. service advisor).

This mobile app, available on native iOS, Android, and HTML5, provides remote service event management capability. Technicians log in to assess a maintenance or repair situation, update repair status, and view asset details such as service history, warranty status, recalls, manuals, fault code information, and more.

Flyntlok and Decisiv can communicate work order information to each other. For example, you can create a case in Decisiv, and push that data into Flyntlok to create a work order. We will be continually improving on this integration over the course of the next few months to make it as streamlined as possible.

If you are interested in using this platform to assist in managing your service department on top of Flyntlok please submit a support ticket in the application and a consultant will reach out.

We have added the job name to the message of parts requests. You can also now check a box to have the WO status updated to "Parts Requested" if you have a work action setup for that status.

If you need this setup please create a support ticket and a Flyntlok consultant can assist.

We added item descriptions to the "Most Common Parts" section of the machine dashboard.

We added logging about who/what is changing when you edit a vendor.

When adding a machine into the system, and a model is not found, allow rent will be set to no by default on the new model.

We fixed a bug causing the inventory sprint count sheet to fail to render.

When editing a DMS Work Order we have added the option to clear the technician so you do not need to delete the technician's name before setting a new tech.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

| Dropdown | Description |

|---|---|

| Quick Quote | A snappy way to get a customer a quote for the machine. |

| Reserve | Create a new reservation for the machine. |

| Sell Machine | Create a sales order with the machine listed on it. |

| Rent | Create a new rental contract with this machine listed on it. |

| Work Order | Create a new work order for this machine. |

| Request Move | Request a new move for this machine. |

| Configure | Attach or detach this machine from another machine. |

| Request Purchase | Create a new purchase request for this same model. |

| Report Loss | File a lost sales report for this machine. |

| Report Loss | File a lost sales report for this machine. |

| Sale Pricing | Configure sale pricing for this machine. |

| New Linked Sales Order | Create a new sales order with this machine linked |

| Most Common Parts | View the most commonly sold parts for this machine |

| RPO Worksheet | RPO calculator for this machine |

| View Timeline | View the timeline of this machine |

| View Model Info | View the model settings for this machine |

| Change Ownership | Reassign the ownership of this machine |

| Legacy Transfer | Change the responsible and physical location of a machine without using the move system |

| Edit | Edit the settings of this machine |

| Delete | Delete this machine (Cannot be undone without filing a support ticket) |