Last Release Notes

September 3rd, 2025 Release Notes

Not yet a Flyntlok Customer?

Learn More at Flyntlok Dealer Management System

YouTube

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity

Service Managers requested the ability to duplicate work orders. Previously, work orders had to be recreated manually, making it time-consuming to set up similar jobs or reuse common work order structures.

Solution

We’ve added the ability to duplicate Work Orders. To duplicate a Work Order, go to the Actions dropdown → Duplicate.

When duplicating, the system copies:

Opportunity

Service Managers noted that when adding jobs directly from the New Work Order form, the warranty customer input is not available. This caused warranty jobs to have no customers, leading to incorrect pricing and forcing staff to re-enter parts and labor.

Solution

We’ve added a Warranty Customer input to the New Work Order form. This field only appears when the job category is set to Warranty

Opportunity

Technicians reported that when adding parts to a Work Order from the mobile view, the bin location was not visible. This forced them to leave the Work Order page and look up the item separately, slowing down the process of finding and picking parts.

Solution

The mobile Work Order view now displays the bin location for parts directly when they are added, allowing technicians to quickly locate items without leaving the Work Order.

Opportunity

Sales Managers noted that when selling multiple machines on a Sales Order, the selection field did not clearly show which machines were already on the Sales Order. This made it difficult to avoid selecting the same machine twice.

Solution

We improved the Sell Machines tab by disabling machines that are already on Sales Order and displaying a message: “This machine is already on the invoice!”. This makes it clear which machines have been added and prevents duplicate selections.

Opportunity

Sales managers requested more control over who can save tax rule changes directly to customer records when working on Sales Orders.

Solution

We’ve added a new Access Control permission for the “Save To Customer” button on tax rules edit. Only users with this permission will be able to save tax rule changes back to the customer record.

Complaint: Rental Managers complained that Reservations tied to reserved Rental Contracts were showing up in the rental timeline view for conflicts alongside the Rental Contracts themselves, leading to confusion.

Correction: Reservations tied to Rental Contracts no longer appear in the conflicts list.

Complaint: Sometimes negative fee-only receiving vouchers failed to post to QuickBooks.

Correction: Fixed. These are now posted to QuickBooks as Vendor Credits.

Complaint: Managers purchasing machines noticed that the descriptions they set on the Machine Purchase Order were not carrying over to their machines once they were received.

Correction: Received machines will get their descriptions from the Machine Purchase Order, with a fall back to inherit the description of their model.

Complaint: Managers reported that they were seeing large negative margins on certain item dashboards, specifically for items that had configured purchasing units quantities (e.g. buying hose by the foot but selling it by the inch).

Correction: Margin calculations now properly account for purchasing unit quantities.

Complaint: Inactive items were showing up in the Parts Used search on the Work Order mobile view, even though inactive items should not appear. This did not happen in the desktop view, causing inconsistent results.

Correction: Fixed.

Complaint: Managers reported saving multiple accounting contact emails works fine on the Customer Edit page, but the next time they load the Customer Edit page only one of the emails are shown. This could lead to accounting contact emails being blown away the next time they save the Customer.

Correction: Fixed.

Complaint: The links on Customer Activity notifications to the Customer Dashboard in the My Notifications report were formatted incorrectly, making them unclickable.

Correction: Fixed

Complaint: Salespeople sending SMS Campaigns with an image attachment noticed some of their messages did not send as expected, and they saw some odd looking (very technical) errors in the Sent Messages details providing the reason why.

Correction: We’ve addressed an issue causing some SMS messages with images not to be sent, and improved clarity around how many SMS messages were attempted and how many sent or failed.

Complaint: When a customer signed a Work Order estimate requested via SMS, the system attempted to send an email to the customer’s phone number. Since phone numbers are not valid email addresses, this generated failed email errors.

Correction: The system has been updated to skip email sending for phone numbers when processing SMS estimate signatures, preventing invalid email attempts.

Complaint: Accountants noted that Machine Purchase Order Vouchers with a negative total would sometimes not post to QuickBooks Online when using a separate distributor currency.

Correction: Fixed.

Complaint: Managers using the “Consolidate Models” feature for their Sales Order PDFs reported their print outs were showing incorrect values for the Back Order column on model lines.

Correction: The back order column now shows a count of model lines that will generate purchase requests and have not been associated with a machine.

Complaint: Salespeople mentioned that when selling a Kit that contained a Model, the green dot "fulfill" action would appear on the Kit line. Clicking on this action would do nothing.

Correction: Fixed a visual bug where the action would appear incorrectly. It will no longer show when selling a Kit that contains Models.

Complaint: When managing parts on Work Orders, Technicians and Service Writers reported seeing backorder warnings when updating quantities of Non-Inventory Items.

Correction: Fixed.

Ivan is officially the Kansas City Chiefs of the Flyntlok league. After dominating last season, he has gone 0-2 this season. (Though in fairness, he lost this week by less than a point.) And poor Alex is 0-2 with a combined point differential of only -2.32. And Isabelle’s Taylor Swift-themed team surprisingly won.

September 3rd, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Our fearless and inestimable CEO and founder Sean McLaughlin gave a talk at the annual Association of Equipment Dealers' (AED) conference in Orlando, FL two weeks ago. Sean gave the talk under the dual position as owner of a 5 location equipment dealer (Craig Taylor Equipment aka CTE) as well as the CEO of a quickly growing software company (Flyntlok!). He focused his speech on the value of technology and the critical role it can play within a dealership.

The main premise is that modern technology is not just a recruiting tool, but it is also pivotal for employee retention. Anyone reading these Release Notes knows the pain and difficulty of finding and retaining employees. Highly motivated staff members want to work with and use modern tools. Old technology is rarely fun or cool. Imagine trying to recruit an employee and showing them a green-screen DMS that was first built 15 years before they were even born vs using a system that allows speech to text for recording complaints/causes/corrections. Further, when you onboard new staff members, you can get them up and running much faster if your dealership adopts modern platforms. Does it suck swapping out old systems? Absolutely! But if you embrace the suck, you'll get to the other side and you'll see a step function in the growth potential of your dealership.

Sean illustrated the direct effects of technology by using his own dealership as a prime example. When he first purchased CTE it was doing $19mln a year, but ten years later it grew to $104mln. Yes, the Flyntlok DMS allowed for a much more efficient dealership with better management of inventory, service, and sales, but he also adopted numerous other best-of-breed technologies that could scale with his business from QuickBooks Online (and later Sage Intacct) to Shopify to SurveyMonkey and Twilio. There was a direct correlation to the adoption of technology to the massive growth of the dealership.

Sean talked about Maslow's Hierarchy of Needs (yeah, remember, he's still a Harvard nerd) and how people are always trying to sell you stuff at the top of the pyramid ("self-fulfillment needs") instead of selling you the core things you need to keep your business running ("basic needs"). Modern cloud based software systems, alongside Artificial Intelligence, are an entirely new evolution of the species. Those who adopt technology will thrive; those who don't will struggle to survive.

Opportunity

Salespeople viewing their list of machines on the mobile view requested the ability to filter out machines that are On Order, like how you can filter Sold machines.

Solution

There is a new checkbox on the Mobile Machine Searcher that allows you to filter out machines that are On Order.

Opportunity

Salespeople have asked to see a Machine’s “Minimum List Price” in the detailed financial view on the Invoice page, as this will make it easier to calculate discounts when quoting or selling a Machine.

Solution

You can now find any Machine’s “Minimum List Price” in the detailed financial view on Machine Dashboard.

Opportunity

Managers requested the ability to streamline their management of similar Models.

Solution

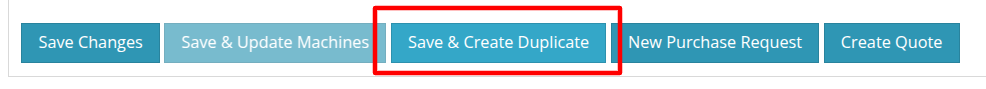

Users can now duplicate a Model from the Model editor page. To do this while creating or editing a Model, click on the "Save & Create Duplicate" button:

This will save your current edits and then create a new Model with all fields duplicated. Note: The newly created Model's name will have the word "COPY" appended to it to prevent duplicate naming.

Opportunity

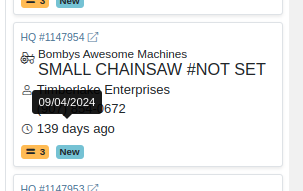

Service Managers using the Work Order Scheduler would like to be able to view a Work Order’s age on the “card” in the Work Order list.

Solution

The age (in days) is now presented on the Work Order “card” in the list of Work Orders, and the created date can be viewed by hovering over the age.

Opportunity

Service Managers requested that $0 customer Invoices be automatically processed when invoicing a Work Order to a regular Customer and separately to a Warranty Customer.

Solution

$0 Customer Invoices will now automatically be processed (moved to Delivered status) when Invoicing a Work Order to a Customer and Warranty Customer Separately.

Opportunity

Service Managers mentioned that it was inefficient (and potentially paper-wasting) to print multiple Pick Lists for a single Work Order that contained multiple Internal Parts Order invoices.

Solution

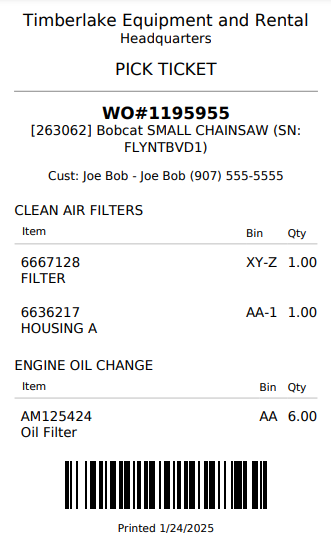

We have added a printable Work Order Pick List in full-page and thermal paper formats. You can access these from the Actions drop-down on Work Order Dashboard:

Parts are grouped by Job:

Opportunity

When a Purchaser is submitting a Purchase Order to an external vendor, they generally only care about the total quantity of an Item to order, regardless of the store's own specific allocations. They requested a way to view Part Purchase Orders by total quantity per Item to streamline their ordering and reduce errors.

Solution

We have added a new toggle to view consolidated quantities on our Part Purchase Order page:

Opportunity

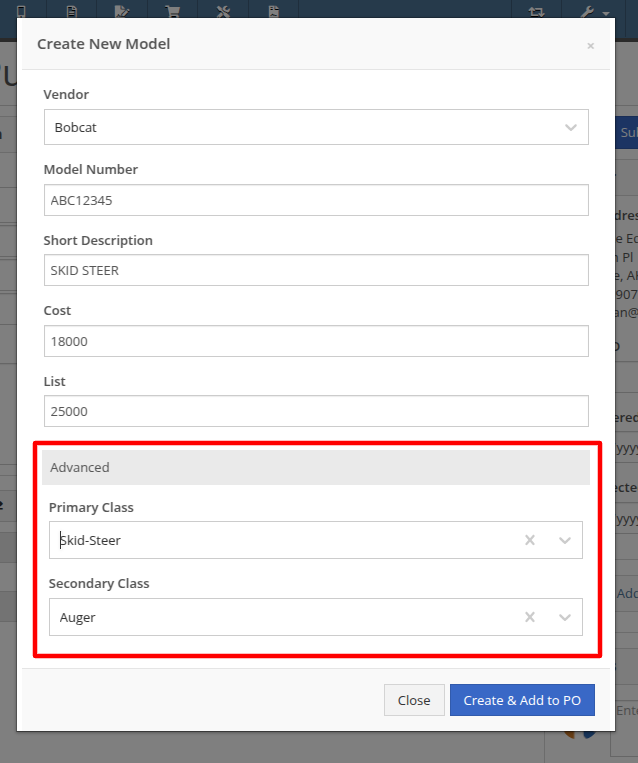

Purchasers requested an enhancement to streamline their Model creation workflows while creating a Machine Purchase Order.

Solution

When creating a new Model from the Machine Purchase Order page, clicking on the "Advanced" section will reveal additional fields to apply to the new Model.

Opportunity

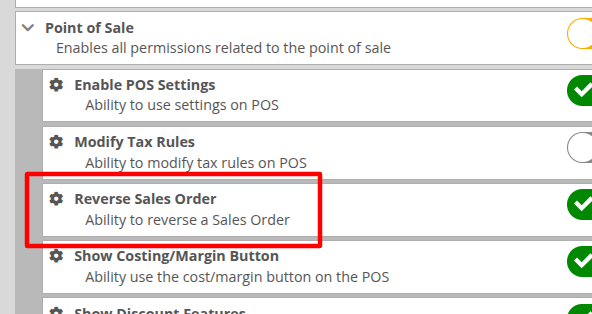

Managers requested additional controls around their Users' ability to Reverse a Sales Order.

Solution

Administrators can access a new permission called “Reverse Sales Order” via the Wrench icon -> Users -> Access Control, under the Point of Sale category. This will keep any user without the permission from reversing of non-Internal Sales Orders.

Note: As with all Permissions on this page, when changing it, the Users must log out and back in for it to take effect.

Opportunity

Managers requested a quicker way to identify Cost of Sale Work Orders associated with a Machine Sale. Previously, the only way to know was to manually review associated Work Orders on the Machine Dashboard and look for Work Orders that had the appropriate Customer assigned to it.

Solution

When creating a Work Order from the original Machine sale, it will now be visible in the "Related Transactions" pop up at the bottom of the Point of Sale screen.

Opportunity

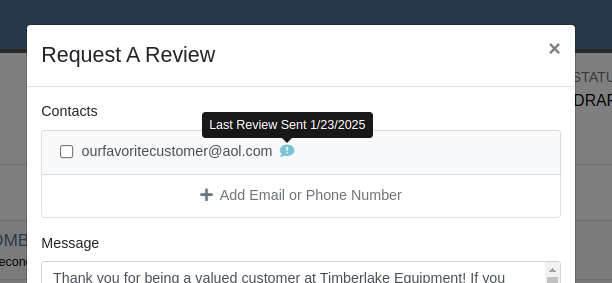

Salespeople requested a way to know if they or anyone in their company had previously sent a Review Request to a customer. They did not want to unintentionally send multiple requests to a long-term Customer.

Solution

When sending a Review Request, users can now see if a Request had been previously sent to a specific email or phone number. When viewing or adding an email address or phone number, an indicator will appear, and hovering over it will reveal the date that a Request was last sent:

Opportunity

Managers requested a way to identify inactive customers when using the Quick Searcher. They were having a difficult time finding customers when there were inactive customers that matched their search, as there was no way to tell the active customers from the inactive ones.

Solution

Inactive customers now have a red indication clearly showing their inactive status, just like parts.

Complaint: Rental Clerks complained to Wayne that from Machine Dashboard, when renting a Machine that had Suggested Items configured, they were not being prompted to select those Items.

Correction: Fixed.

Complaint: Salespeople reported that when swapping out a Machine on a Sales Order, the swapped-out Machine sometimes remained in Sold status.

Correction: This happened on an invoice that was past “Draft” status. Fixed.

Complaint: Salespeople reported that Will Call Labels on Item Receiving Vouchers sometimes didn’t display the full Customer name and Sales Order reference.

Correction: This was occurring on labels with longer names. Fixed.

Complaint: Rental Clerks complained that on the New Rental page, when switching between List and Timeline views, sometimes the availability information on Models or Machines would appear inconsistent between the two views.

Correction: Fixed.

Complaint: Managers mentioned that they were able to unintentionally create Models with the same name and Vendor, causing confusion around reporting and searching.

Correction: Updated the Model editor page to prevent creating or editing Model names that match an existing name on the same Vendor.

Complaint: Salespeople reported that they would receive an error due to phone number formatting when navigating to a new Lead that was created from the Customer dashboard.

Correction: Fixed.

Complaint: Salespeople mentioned that the searcher on the All Leads page would sometimes display an error.

Correction: Fixed.

Complaint: Purchasers noted that on Part Purchase Orders, the warning for Vendor minimum order amount was always visible, even if the order was over the minimum amount.

Correction: Fixed. This warning should now only show when the Purchase Order's total falls below the Vendor minimum.

Complaint: Service Managers reported that sorting by priority on the Work Orders Service Scheduler did not sort the list of Work Orders properly.

Correction: Fixed.

Complaint: Sales Managers reported that orders coming from Shopify into Flyntlok were being discounted if the order was for an existing Flyntlok customer that had discounts.

Correction: Fixed. Customer discounts will be ignored to ensure the invoice total lines up with what came from Shopify.

Complaint: Parts Managers reported that Part Purchase Orders were not always being closed when all parts were received.

Correction: Fixed.

Complaint: Parts Managers reported that Quantity On Hand was not being adjusted on Parts substituted on Part Purchase Orders.

Correction: QOH was being updated, but we needed to do a forced-refresh of the page to show the updated value.

Complaint: Managers noted that when adjusting the MSRP of an Item, the Vendor default markup was not being applied to List Price.

Correction: Fixed. This only affected locations that were not using Price Matrix calculations.

Complaint: Rental Clerks complained that on the New Rental page Timeline view, Machines with an "On Contract" Conflict were being displayed as Available.

Correction: Fixed. "On Contract" Conflicts should now correctly show the orange-colored indicator as shown here:

Complaint: Fleet Managers with the Samsara integration mentioned that their Machines were not being updated with hours or mileage data from Samsara.

Correction: Fixed.

Complaint: Part Receivers reported that the Part Receiving Voucher would appear to have no parts data initially, then the table’s lines would load.

Correction: Fixed.

Complaint: Parts Receivers reported that, when adding fees to Vouchers, they had to click into the Action field before being able to type when they didn’t need to before.

Correction: The cursor now automatically appears in the field when you add a new fee.

Complaint: Parts Managers reported that superseding Parts on Part Purchase Orders would sometimes fail without indicating why.

Correction: Fixed.

Complaint: Service Managers reported that parts from Invoices that had been unlinked from Work Orders would still appear on Estimates generated later.

Correction: Fixed.

Complaint: Shopify Managers reported that they were unable to see information about Shopify-linked parts in Flyntlok.

Correction: Fixed. Shopify made unannounced changes to their integration that Flyntlok was not made aware of until it was too late. Sometimes we just gotta roll with the punches.

Complaint: Inventory Managers noted that when removing an Item from a Sales Order that was linked to a Purchase Order, the Purchase Order’s page would not show that the Item had been unlinked.

Correction: Fixed.

Complaint: Salespeople mentioned that when searching for a Machine, searching by using words in the Machine's description would return inconsistent results.

Correction: Fixed. Now when you search for a Machine, Flyntlok will once again partially match your search term against words in the Machine's description.

Complaint: Service Managers reported they were unable to link a Sales Order back to a Work Order after it was unlinked.

Correction: Fixed.

Complaint: Part Receivers reported they were receiving an unintelligible error if they received an item at zero quantity.

Correction: Fixed. The error now explains that you cannot receive zero quantity of an item.

January 15th, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity:

Salespeople have requested the ability to set up a temporary discount on an item for a customer so that each time that customer buys that item there is a default discounting rate set. This will save users time from having to re-add the discount from the Point of Sale and serve as a reminder that the customer has that discount available.

Solution:

We have added a new "Item Discounts" module to the Customer Dashboard that will allow users to add and edit individual item discounts and set a specific expiration date for the discount. This new module will be found in the Action Buttons drop-down menu.

We have also updated the discount structure of the Point of Sale to incorporate the Customer Item discounts so that you can save a new discount directly from this screen. When adjusting/discounting the list price of a line item from the POS, Flyntlok will now give users the option to save that discount to the customer. Item discounts saved via the POS will then populate the "Item discounts" module of the Customers Dashboard.

Opportunity:

Flynlok offers users an option to email a "Signature Request" or "Lease Agreement" to customer contacts to confirm the rates and values of a Rental Contact. Currently, the email sent out is including our Flyntlok logo and mailing address. Because this can be confusing to recipients that are unaware of Flyntlok, our users have requested to have their actual company logo and address information added instead of Flyntlok's.

Solution:

We have added a new option to upload a custom Company Logo image on the Flyntlok Settings page.

To set a custom Company logo that will display on the Rental Signature Requests and Lease Agreement Emails, you will navigate to the "Admin Editor Wrench"  icon in the upper right corner of the home screen and select the "Flyntlok Settings" option from the drop-down menu. From the "Flyntlok Settings" page select the "Company Logo" link and upload a custom Company image from your device. Once uploaded this image will be displayed on the Rental Signature Request and Lease Agreement Emails.

icon in the upper right corner of the home screen and select the "Flyntlok Settings" option from the drop-down menu. From the "Flyntlok Settings" page select the "Company Logo" link and upload a custom Company image from your device. Once uploaded this image will be displayed on the Rental Signature Request and Lease Agreement Emails.

Opportunity:

We recently released a new feature that allows users to merge open Special Ordered quantities into an existing Purchase Order. The issue is when multiple Special Orders are merged into the same PO they are combined into one line item. This makes it unclear that the remaining quantity from the original Purchase Order is not related to the Special Order. It was also not possible for multiple Special Orders to be merged into the same PO for the same item. Flyntlok users have requested that merged Special Orders populate the PO in individual line items.

Solution:

We have updated the Special Order merge functionality so that when merging a Special Order (or Orders) into an existing Purchase Order, the PO will display each Special Order as individual line items distinct from the original PO quantity.

Opportunity:

Flyntlok now offers Users the ability to merge open Special Orders with regular Stock Orders when using the Flyntlok Draft Stock Order page. Purchasing Managers have requested a more obvious indicator when an item has open Special Orders available to merge with Purchase Orders.

Solution:

We have added a new " Has Mergeable PO" icon to the Special Orders column of the Draft Stock Order page. This new icon will be displayed with open Special Orders quantity only when there are available PO's to merge the Special Order quantity into.

to the Special Orders column of the Draft Stock Order page. This new icon will be displayed with open Special Orders quantity only when there are available PO's to merge the Special Order quantity into.

Opportunity:

Salespeople would like to see how many days or months an individual open Lead has been active. Flyntlok currently displays the Lead creation date on the Leads report but does not calculate a day's active "age".

Solution:

We have added a new "Age" field to the All Leads report which will display the individual Leads' age by days based on the creation date.

Opportunity:

Flyntlok offers customers the ability to have a "Text Us" widget on their company website, which allows potential customers to submit inquiries to the company. Flyntlok then takes these incoming messages and generates a new CRM Lead for this potential customer. Salespeople have requested that the associated location and department be added to the new Lead's name.

Solution:

If you have Branch Locations and Department fields set up on the "Text Us" widget, Flyntlok will now apply this information to the new Lead's name.

Opportunity:

Flyntlok offers users multiple different ways to edit and document the mileage from a Machine's odometer through the course of a Service Work Order. Users have requested a new report that will display a history of mileage logs for a specific piece of equipment.

Solution:

We have added a new "Mileage History" section to the Machine Dashboard which will display all Work Order check-in mileage logs as well as any edits to the Miles field of the Machines edit page. This new section will display the ten most recent entries as well as a link that will redirect users to an alternate view that will display ALL mileage logs for that Machine. Flyntlok will display the date, the mileage, and the user's name that performed the logging.

Opportunity:

Sales Managers using the new Gravity Payments emergepay system have requested billing address fields be added to the Text2Pay payment type. Gravity Payments offers additional discounts for enabling fraud protection steps, such as billing address fields, on the Text2Pay payment option. Flyntlok currently does not provide the billing address details over to Gravity for address verification.

Solution:

We have added the billing address details to the Text2Pay settings. Default billing information (pulled from the Customer's Dashboard) will auto-populate into the payment system when the Text2Pay option is selected, but Users will also have the option to edit this new field. N.B. Editing the address fields here does not update the original contact record.

Opportunity:

Rental managers in Anchorage, Alaska would like the option to apply a Municipality-specific tax charge on the rental of motor vehicles. Anchorage requires the collection of an 8% tax on the rental of motor vehicles with a 30-day cap of $240 for trucks, vans, and RVs or a $120 cap on all other motor vehicles.

Solution:

We have added a“Charge Municipality of Anchorage Tax” field to the Model Dashboard's edit page, which allows users to associate the specific MOA tax charge to all Machines of that particular model. We have also added a new “Charge Municipality of Anchorage Tax” check-box on a Rental Contract, that when selected, will charge the specific tax rate on the Rental Contract. This box is auto-selected when a contract is created but can be overridden by the user.

Complaint:

Flyntlok users were experiencing an issue when trying to email Sales Order PDF documents to customers where the contact record contained an email address but no contact name. In this scenario, the Flyntlok user received an error and the email was not sent.

Cause/Correction:

Fixed.

Complaint:

Flyntlok users were having an issue when trying to manually type in the start date of a Rental Contract, rather than using the date picker. In this scenario, the page would error out and users were then redirected to an error page.

Cause/Correction:

Fixed. Flyntlok users will be able to type out dates without having to break the keyboard stride.

Complaint:

Users were experiencing issues where sold Machines were able to be added to a Rental Contract via the "Actions" button of the Machines Dashboard.

Cause/Correction:

Fixed. We have removed the ability to select the "Rental Contact" button from the Machines Dashboard when the machine is in a "Sold" status.

Complaint:

When an item's description is lengthy, the generated PDF document from the Point of Sale moves the entire item line to a new page, creating an awkward formatting issue. Flyntlok users have requested that the unnecessary extra spacing be removed from PDF documents generated from the POS.

Cause/Correction:

We have updated the Point of Sale PDF allowing item descriptions to be broken up between two pages.

Complaint:

Users reported an issue when they were adding an Item onto an existing Sales Order where that Item already had previously been added to the SO and where they merged the two line items into one. In this scenario, the Purchase Plan would only account for the original Line Items' order quantity and did not reflect the updated merged quantities.

Cause/Correction:

Fixed. Purchase Plans will respect the combined quantity set from the Point of Sale.

Complaint:

Service Managers were experiencing an issue when applying a deposit to a Service Work Order where, the deposit was not auto-populating onto the final invoice.

Cause/Correction:

Fixed. The deposit will auto-populate on the final invoice.

Complaint:

Users were experiencing an issue when trying to invoice a Work Order with both Warranty jobs and Customer jobs. The customer invoice that was generated displayed costs on items associated with Warranty jobs when they should show up as $0.

Cause/Correction:

Fixed. All the warranty jobs, parts, and labor are included on the customer bill at $0 cost and $0 list.

Complaint:

Rental Managers were experiencing an issue when closing a Rental Contract, where the Contract had been fully paid for on a previous invoice including all fees and charges, Flyntlok was still generating a final invoice for $0.00.

Cause/Correction:

Fixed. Flyntlok will close the Rental Contract and no additional invoice will be generated.

Complaint:

Users were running into an issue when attempting to see how many of a certain Machine Model their company has sold, from the Sold Machines report. The report was excluding results due to a max capacity set at 15,000 results per page.

Cause/Correction:

We have increased the results limit of the Sold Machines report to 25,000.

(And kudos to you folks for selling more than 15,000 machines.)

Complaint:

Salespeople were having issues with Customer Sparks Orders not displaying the Stock available to transfer from other branch locations.

Cause/Correction:

Fixed. Spark Orders will display available stock from other branch locations. This information will be indicated by the (*) icon in the item line's QOH box.

Complaint:

Ok, bear with us here as this is a confusing bug: If a user took a Deposit (e.g. $50) on a Work Order then the Customer has a balance of $50 (since the WO is still in progress). Then you later go and sell a part to the Customer for $30 and you apply the payment using the “Deposit” payment type. The balance for the Customer should now be $20 since you just used part of their earlier Deposit for this sale. Later you go and finalize the invoice for that original $50 Work Order. The Customer should only have a balance of $20 now, but the invoice for the Work Order was still showing the original $50 deposit. Later you find out the Customer owes you $30!

Cause/Correction:

Fixed. The Work Order will now know if the deposit was partially (or completely) used on a separate transaction.

Complaint:

Service Managers were seeing a discrepancy between the timestamps displayed on the service technicians' "Timecard" Report and the actual Work Order.

Cause/Correction:

Fixed. We have addressed a timezone error on the "Timecard" report. Flynlok was incorrectly displaying clock-in/out times in the Alaska standard time zone regardless of the company location.

(Lesson learned: World does not revolve around Alaska.)

Complaint:

Flyntlok users were receiving an "Error Sending Message, Contact Flyntlok for Assistance" notification when attempting to send an SMS text message from the CRM Hub when there is an invalid phone number.

Cause/Correction:

We have updated the message displayed when attempting to send SMS messages with invalid phone numbers. (N.B. Flyntlok does not know if the number used is in service or is capable of receiving SMS messages, simply that the number/format was not valid.)

August 2nd, 2023 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity:

Flyntlok users would like a way to better manage Work Orders that contain Warranty Jobs. It would save time if users could invoice both Warranty related and Non-Warranty Jobs on the same WO because currently, Flyntlok requires two separate Work Orders.

Solution:

We have added a new setting that your Administrator can set which will then create multiple invoices for each Work Order that contains Warranty and non-Warranty related Jobs. We have also added a new field on the Job level called Warranty Customer which will default to the Vendor of the Machine associated with that job. If a WO has multiple Warranty jobs associated with different Vendors, Flyntlok will generate a separate invoice for each of the different Vendors. The invoice for the final Customer will show zero cost for any Warranty related jobs.

To relate a Vendor to a Warranty Customer, we have added a new field to the Customer edit page where you can specify the Vendors related to a Warranty Customer. (A Warranty Customer is a customer record in Flyntlok to which you would invoice work completed on a Warranty for a Vendor.) You can only set Warranty Vendors if the Customer type is set to Warranty.

Opportunity:

Service managers have requested the ability for techs to be able to switch users from within the Mobile View on a single shared device. Currently, Flyntlok allows only administrators the ability to switch between alternate users' Flyntlok profiles within the company and only when in the Desktop View.

Solution:

We have added the Switch User feature to the Mobile view. You will now see the Switch User icon  in the top right corner of the Mobile View's home page, and we will display the name of the now-current user below the navbar, making it clear who is logged in. This is a client-based setting. Please reach out to the Flyntlok support team if you would like this set up!

in the top right corner of the Mobile View's home page, and we will display the name of the now-current user below the navbar, making it clear who is logged in. This is a client-based setting. Please reach out to the Flyntlok support team if you would like this set up!

Opportunity:

Service managers have also requested the ability for technicians to create new Work Orders directly from the Mobile View on a single shared device. Currently, the new Work Order button of the Mobile View takes you to the Desktop Work Order creation page.

Solution:

We have created a mobile version of the Work Order creation page.

Opportunity:

Flyntlok Purchasing Managers would like the ability to combine Special Orders along with regular Stock Orders when using the Flyntlok Draft Stock Order page. This will save time by allowing users to combine these orders with fewer steps than before. There is currently no way to combine quantities from the Draft Stock Order.

Solution:

We have added a column that will display the Special Order amount that is contained on a Special Order PO located next to the recommended quantity, in addition to the existing Order Qty field. If the user clicks on the drop-down arrow on the part, under the “Open Special Orders” there is a “Merge” button that allows for the combining of the Special Order with this Stock Order. Flyntlok then “reserves” the Special Order quantity.

Opportunity:

Flyntlok users have requested a centralized Purchasing Report that shows the value of demanded items with the ability to generate a purchase order based on the demand.

Solution:

We have added a new "Purchasing Hub" report that will summarize the value of demanded Special Order and Stock Order items by Vendor or Distributor. From the report, you will be able to generate a Draft Purchase Order to purchase the Special Order items, Stock Order items, and any other items under that Vendor or Distributor.

Flyntlok Administrators will have the option to add this new report to the Left-Hand Navigation Menu by navigating to the "Admin Editor Wrench"  icon in the upper right corner of the home screen, then select the "Navigation" option from the drop-down. The Purchasing Hub report can be added to either the Parts or Purchasing tabs of the Navigation Menu.

icon in the upper right corner of the home screen, then select the "Navigation" option from the drop-down. The Purchasing Hub report can be added to either the Parts or Purchasing tabs of the Navigation Menu.

Opportunity:

Flyntlok users would like to specify whether a contact can be included in email or SMS text messages directly from the Contact's Dashboard. Currently, if the contact is not set up to allow SMS/email correspondence, users will have to navigate to the Customer Dashboard to edit this setting.

Solution:

We have added the "allow email/text" flag to the Customer Contact Dashboard.

Opportunity:

Salespeople have requested the ability to edit a Machine directly from a Sales Order. Currently, when a Machine is added to a new Sales Order, Flyntlok supplies a link to the Machine's Dashboard. However, there is no option to click on a link that brings users straight to the Edit Machine Information page.

Solution:

We have added a new  icon to the Machine item line in the Point of Sale, which will redirect users to the machine edit page when selected. This will save users extra clicks!

icon to the Machine item line in the Point of Sale, which will redirect users to the machine edit page when selected. This will save users extra clicks!

Opportunity:

In the original Payments screen, Flyntlok offered an "Apply and Process" option that would auto-order the associated Sales Order, removing the additional step of manually clicking the Order button after processing payment. The new and updated payment screen lacked this "Apply and Process" option. ( This new payments screen is only currently only available to users of the new Clover Payment devices. If you wish to upgrade your payment devices, please reach out to your friendly Flyntlok consultant or a Gravity Payments representative.)

Solution:

We have added the "Apply and Process" option to the new Payments screen.

Opportunity:

Salespeople have requested that the payment date displayed on the item line in the Sales Order be added to PDFs generated from the Point Of Sale.

Solution:

We have added the payment date to the details of the payment lines on the PDF copy.

Note- This will not backfill on existing payment lines.

Opportunity:

Flyntlok users have requested Machines that have been set with a Primary or Secondary class have this information displayed within the Machine's Dashboard. This information is also displayed within the information display of a Machine when adding to a Work Order.

Solution:

We have added a new "Class" section to the Machine's Dashboard and to the information display of a machine on the Work Order creation page.

Opportunity:

Salespeople have requested an indicator of Stale Parts be added to the item searcher of the Point of Sale.

Solution:

We have added a Stale parts indicator to the item searcher results. If there is QOH of an item at a different location, Flyntlok will show an asterisk in the QOH box of the searcher to indicate that the item is on hand at another location. If there is QOH in another location and the part is stale, it will indicate as such by red text and the asterisk. Hovering over the QOH box will show the status and the QOH in alternate company locations

Complaint:

The Item Dashboard was displaying incorrect On-Order Quantities when there were still Receiving Quantities on open Voucher/Purchase Orders. The On-Order Quantity shouldn't include Received Quantities, even if the Voucher/PO was not closed.

Cause/Correction:

On-Order Quantities now reflect Received Quantities regardless of the status of the PO.

Complaint:

Users could reverse a Sales Order while it was still posting to QBO.

Cause/Correction:

Fixed. Our development team was able to update the QBO settings to block a reversal if the transaction is still processing.

Complaint:

Flyntlok users have been experiencing an issue where the printed invoice of a split Sales Order did match the invoice on the Flyntlok screen.

Cause/Correction:

Fixed. This issue was caused when one of the split invoices was deleted. In that instance, the master invoice was not removing the details from the deleted invoice. The printed master invoice will no longer include the deleted split invoice details.

Complaint:

Flyntlok should display a warning message to users when attempting to create a new Machine if the Serial Number is associated with another Machine in your inventory. Currently, this message is only displayed when creating new Machines via the Left-Hand Navigation's “New Tab.” Flyntlok users have requested this message also be displayed when using the Machine Quick-Create functions from the Point of Sale and the Work Order creation page.

Cause/Correction:

We have added a Duplicate Serial Number warning to the machine quick create features.

Complaint:

Flyntlok users were able save the Model without a Make.

Cause/Correction:

The Make field is now required when creating/saving a Model.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System.

We are holding a click reduction contest. If you have ideas that could reduce clicks and speed up your workflow in Flyntlok, please submit them using the rabbit button! We will pick the two most impactful ideas, and the winners will receive a $25 Visa gift card. Winners will be announced in the September 28th release notes.

Stihl equipment can be registered with Stihl through Flyntlok. When you view a machine that has been registered, you will get product information that is provided by Stihl.

To register a machine, go to that machine's dashboard and click the New Registration button. Then fill out the product registration form.

The work order creation form can be customized to show only the information needed. The default form is on the left, and a customized version is on the right.

If you would like to edit your work order form. Please submit a support ticket and the Flyntlok consulting team will help you out!

We have added the efficiency metric to the header of the performance tab. Efficiency is calculated by taking the work order Actual Hours / Billable Hours.

This metric is also calculated per job and displayed in the Job Finance section.

Each job on a multi machine work order can be assigned its own tag.

Tags are displayed on each job tab.

Machine creation on the new work order form has a description field.

We have added a margin column while selling machines from the point of sale.

You can update a customers licensing information while creating a rental contract. If you would like to save this information back the customer make sure to check the Save License to Customer box. License information can also be updated from the Info Tab.

This feature will help keep customer licensing information up to date.

August 31st, 2022 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System.

We've made it easier to sort and filter the list of machines when adding machines to a voucher.

While adding new machines to the voucher, you can now designate a quantity of machines to create.

We have added label printing functionality to the bulk actions! Don't forget - Flyntlok consultants can customize these labels to your business needs. Just submit a support ticket!

We added permission that must be turned on if the user would like to complete vouchers. You can also designate a user to receive a notification and pending action when a voucher is submitted for completion.

We have removed the recalculate button and will recalculate the fees live.

If you add a date and leave the year blank, we will assume that you would like to use the current year.

If a machine received on a voucher has files attached to it, you will see a voucher files section on the machine's dashboard. Remember, files attached to a machine using the detail view will be attached directly to the machine.

If you track your payables through bill.com, we have added the ability to set up a bill.com machine clearing account. If this is set, we will offset the asset amount on the journal entry to this account.

If you log in from a phone, you will now be taken directly to the mobile view. If you want to return to the desktop version, click Return to Desktop at the bottom of the page!

The work order you are clocked into will display at the top of the page. The My Work button will show you all of the work orders you have assigned to you.

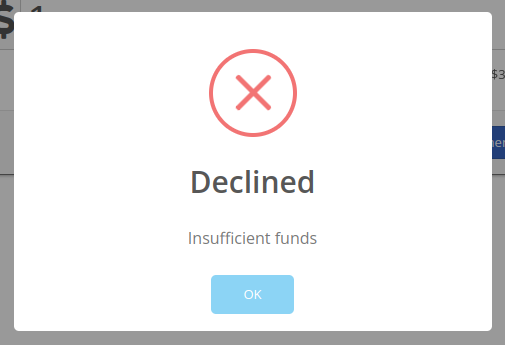

We've updated messages coming back from our card processor to make it more clear when a card has been declined or if there was an error during the payment process.

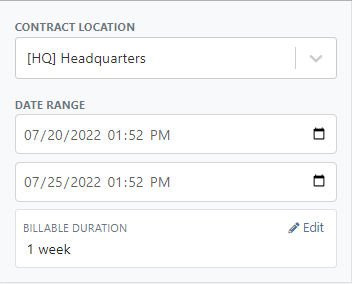

We will be beta-ing a new feature with pilot dealers that should make it much easier for us to properly calculate your billing durations given a date range on a calendar. This should allow you to set up contract data in a much easier format and reduce the number of dates you need to manage for a rental contract.

We will be beta-ing a new feature with pilot dealers that allows you to set a default interim billing cycle for a contract. This should greatly reduce existing date adjusting when trying to create an interim invoice. This will also let us notify you when you have a contract due for billing, and in the future, offer us the chance to generate these bills automatically for you!

You can now select a location during the rental contract creation. Previously, we only allowed you to change it once the contract was created.

While entering an address on a rental contract, you can now click the Save to Customer box to save the address to the customer address book.

Consumables can be configured in two different ways: Standard and Capacity-Based. Capacity-Based is better for fuel because fuel is measured in percentages, not quantities. Standard is better for renting out consumables that are measured in units. Tire wear, cutting edge wear, and other specifically measure consumables should be setup with the Standard style.

When auto-generating work orders at rental check-in, we were using the machine's last known hours, not the hours at check-in. That has been fixed, so work orders populate with the machine's hours at check-in.

We fixed a handful of bugs causing the work order error when you tried to save. Some of the most notable are:

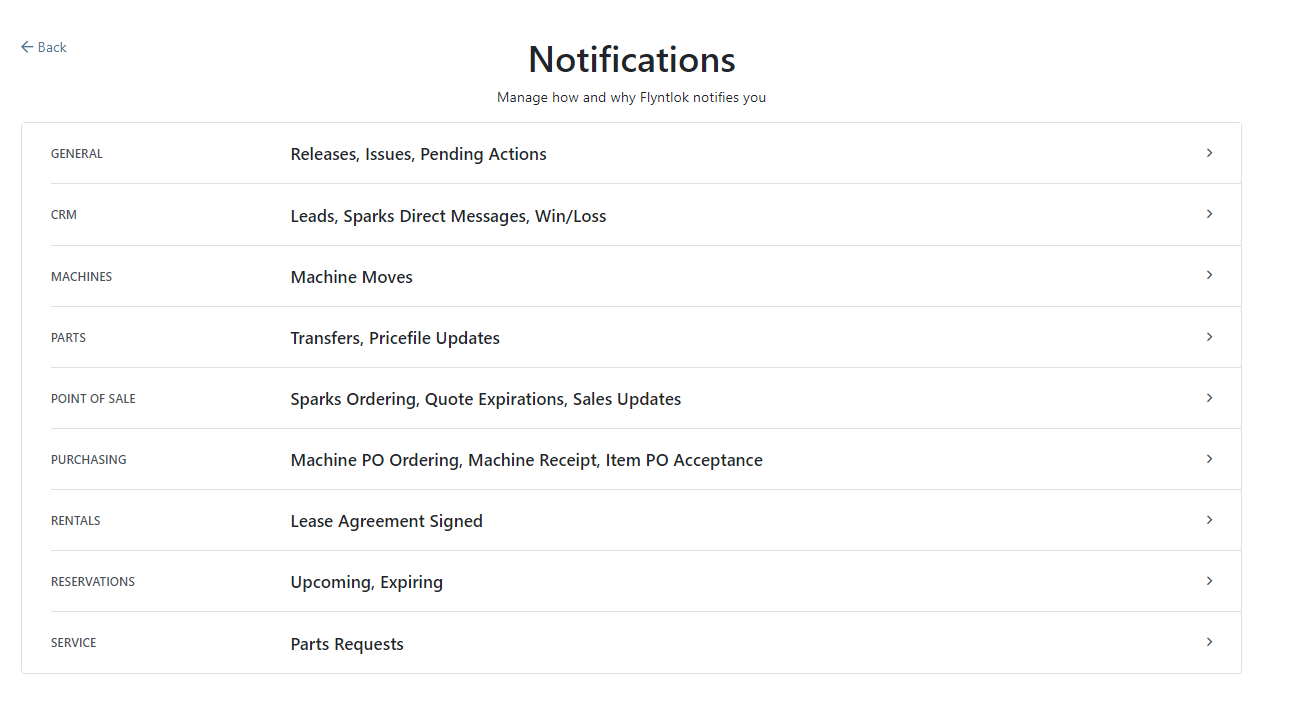

Notification groups should now be more clear in which aspect of Flyntlok they tie to.

Along with adding more categories of notifications, we added a new notification you can receive if a CRM Lead gets assigned to you. You can configure how you would like to receive this notification by clicking your name in the upper right of Flyntlok and heading to preferences -> notifications.

We've added an option on the customer profile to decide if you keep the customer's accounting contact in sync with Quickbooks Online data or if the data you enter in Flyntlok should be the source of truth. This is the email we use to auto-send invoices and receipts. When this is on, we will always override what is in those fields with what is set in QuickBooks Online. When it is off, the contact and email will remain whatever you enter under the customer profile in those fields.

We were presenting you with some errors almost anytime you ran the end-of-day process to post customer payments. Those errors were erroneous in that the posting had gone through successfully. We prevented those unnecessary errors from displaying going forward. Actual errors still display!

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System.

We have restructured the customer panel to make it more space-conscious and moved the contact selector next to the customer selector. Previously, the contact was selected in the details panel at the bottom of the page.

You can now designate the type of invoice and use that for reporting.

The type and location can also be encoded into the ID. If you wish to enable this feature, please submit a support ticket.

We have made it easier to add/edit notes and send SMS's from the point of sale by adding an activity panel on the lower right of the page.

When a customer responds, you will get a notification in the lower right of Flyntlok, and on your dashboard.

You can reply from the notification, customer dashboard, or right in the activity panel on the invoice.

Previously when creating a return for a sale that includes cores, we were not populating the return sales order with the dirty core. We updated that so you no longer have to add that manually when the customer returns with the dirty core.

We have updated the sales order PDF to reflect the machine owner if it is different than the bill-to.

You can now customize your own templates for SMS's sent from the work order system! To configure your templates, please submit a ticket and a consultant will work with you to get them setup.

We have added an unread activity indicator on the activity panel. Once you open the panel, the notes will be flagged as reviewed and the indicator will be removed.

We have added icons to the estimate section to indicate when an estimate has been emailed to your customer, and when they respond. Look for more updates to this feature in the coming releases!

We have added an unread activity indicator on the activity panel. Once you open the panel, the notes will be flagged as reviewed and the indicator will be removed.

![]()

Based on your company's settings, we will automatically create a work order at the first rental, and every subsequent check-in of a rental. We updated this functionality to create these work orders as segmented. In the coming release, you should be able to designate one or more job templates to be added to this style of work order.

We moved the bulk printing of labels from the PO to the voucher. This lets you print off a barcode label for each item you are receiving.

Previously we were updating the Accounting Email and Auto-Send setting on the customer when you re-loaded them. That caused confusion when QuickBooks Online had different data than what was set in Flyntlok. We will no longer automatically update those fields.

November 17th, 2021 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System.

In the past, only one machine was allowed per work order. This worked great until a customer dropped off a chain saw, pole saw, and weed wacker. Now you can add multiple machines to a work order. To do this, click "Multiple" on the work order creation screen. Then add machines to each job.

Then, you will be able to add a machine to each individual job.

Click the Info Tab to see a list of people that are clocked into a work order.

The customer will not see any notes that are added in the "Notes" section. However, after the notes have been reviewed, you can add them to the correction section by clicking the "Add to Corrections" button.

When you minimize a section on the info tab of the work order page, it will remain closed until you open it again.

Parts invoices can be transferred between jobs. The jobs can even be on different work orders. Click the transfer button on the management tab to preform transfers.

![]()

Certain work order actions only need to be available to select users. Below is a list of actions that can be limited. The limits can be set on the Authorized Users tab by your company Flyntlok administrator.

If you are interested in upgrading to the new rental system, please reach out to consulting@flyntlok.com.

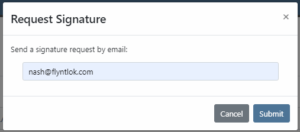

From a rental contract, select "Request Signature" from the actions dropdown.

Then input the customers' email on the pop-up.

The customer will receive an email prompting them to e-sign the contract.

Then, the customer can sign the contract.

Beta users can configure Kits from the Models page. To create a Kit from scratch, first, create a Model. Then edit the model and scroll down to the recommended items section.

Remember, only items that are marked rentable will show in the searcher.

If you leave the box blank, the rental delivery fee will show TBD instead of $0. This allows you to bill the customer after the delivery has occurred. In this case, we recommend having your rates listed in the terms of the contract.

You can now associate more than one salesperson to a Customer. This can be helpful if a customer has a salesperson and a PSSR.

You can now see the last time a customer was surveyed on the customer's dashboard.

![]()

We have updated vendor searching from the search bar. It should be faster and show better results than before!

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System.

By request, we have been moving users over to the new work order system. Thank you for all the great feedback! Please submit a ticket if you would like to start using the new system.

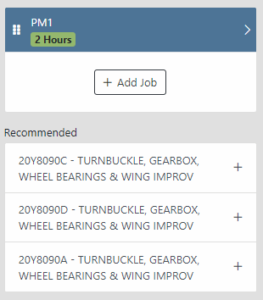

After creating a work order for a John Deere or Hitachi machine, we will look for open PIPs. If any are found, they will be listed just below the Add Job button in the new Recommended section of the work order.

Once you select a recommended job, we will pull information directly from John Deere like the PIP title, type, and even the items needed for PIP. If you choose to create the job, we will also create the internal parts order with the required parts for the job.

In order to save you time on creating templates for common jobs, you can now create a job template directly from a job you have on a work order.

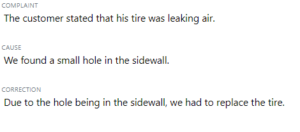

In our new work order, we have moved away from work requested and work done on jobs to a complaint, cause, and correction structure. This gives the opportunity to input the customer's complaint, then the technician's analysis of what caused the problem. The correction field will be used to communicate the work done. Only complaint and correction are required.

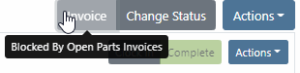

Description labels appear when a button is disabled to give insight as to why the button is disabled.

Banners are back! After getting a new look, banners are being reintroduced to update you on important information.

![]()

![]()

We will soon be adding more customers to the new rental system. Here are some of the new features that will be available!

We now support renting out items. To make an item rentable, you will need to edit the item and check the Item Can Be Rented box.

While you are there, you can add rent schedules to cover all of your pricing structures.

A rental kit consists of one machine and a group of items that must be rented together. An example of this is renting a serialized air compressor with a hose and pressure regulator. The air compressor is the serialized machine, while the air hose and pressure regulator are optional items. When adding the machine to the rental, you can choose the amount of each item you will rent with the machine. These items will then be pulled from inventory when checked out, then added back to inventory when checked in.

We now support customized email templates on each survey template that you send out. If you are interested in adjusting your email template or learning more about our survey system, please reach out to consulting@flyntlok.com!

If you are a multi-store company, you can now configure your surveys to only send when the sale is closed at a certain store.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Check out the latest updates to the Flyntlok Equipment Dealer Management System.

When stock orders are received, Flyntlok will help find where they will be used best. If you have outstanding special orders for the same part; you will be able to move the stock order part onto the special order from the receiving pop-up.

Flyntlok now automatically checks to see if your rental customers' licensing is up to date. You can continue with the rental on a case-by-case basis.

To implement this check at your business go to the Wrench->Flyntlok->Flyntlok Details. Then under the rental section make sure "Require Valid License for Machine Checkout" is selected.

Flyntlok now displays a warning if you add a duplicate item to a sales order. Choose to either combine the item with an existing line item or create a new line item.

Don't receive this report? Reach out to consulting@flyntlok.com to get it set up.

Flyntlok will now verify fleet pricing on work orders. Add the customer's fleet number during work order creation or from the edit screen to take advantage of any discounts. We are continuing to further automate this process.

When a customer is changed on an existing sales order, any discounts will be recalculated. This will ensure every customer is charged the correct amount.

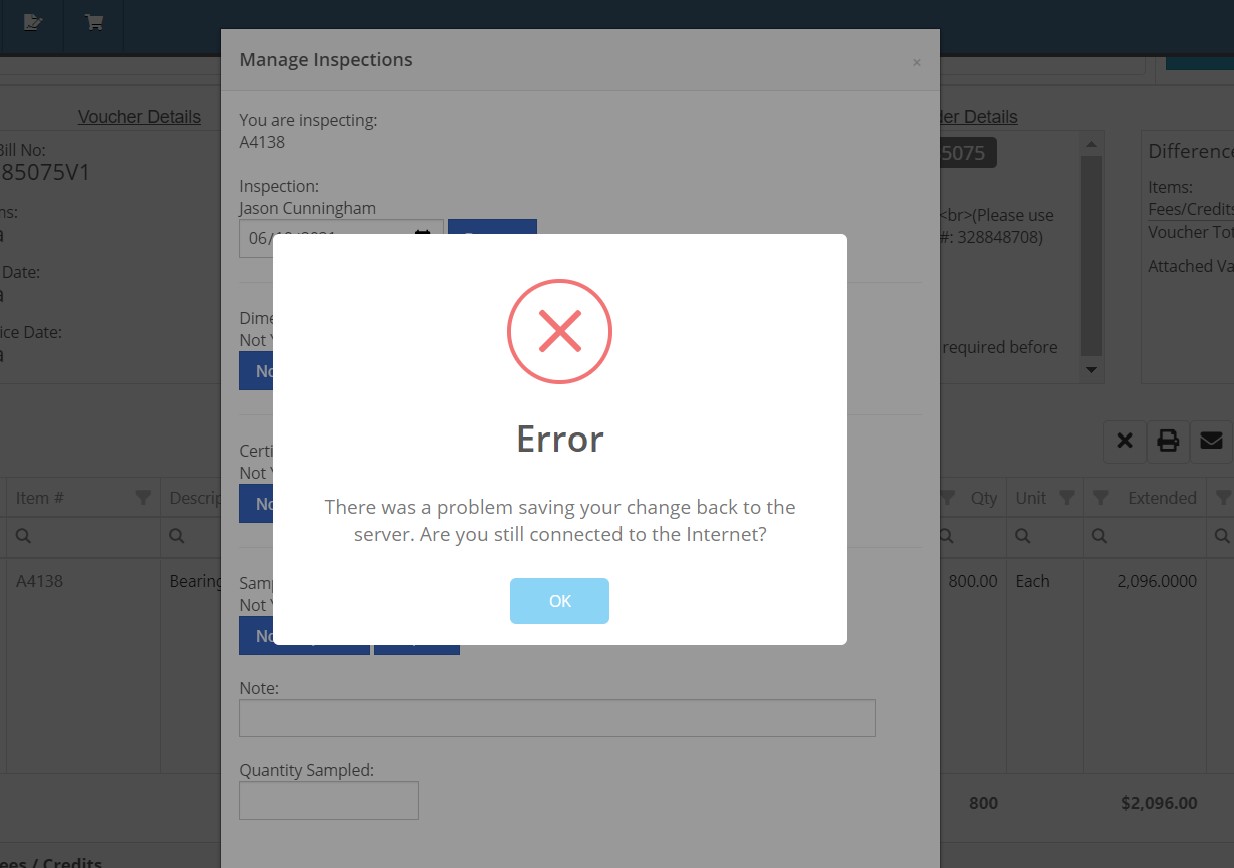

When inspecting parts on ERP vouchers the below error would occur. This has been fixed on all vouchers created after 6/30/2021.

After a Voucher has been closed it will be "locked down". Users will not be able to add or delete attachments, edit attachment values, or make changes to fees and credits. We remove the buttons altogether, see below!

![]()

![]()

Flyntlok will assume you are inputting days when a number is typed into the rental duration text box. You can still use "w" after a number to set weeks and "m" to set months.

Flyntlok had been setting the default salesperson to the first person shown in the dropdown; which is ordered alphabetically. The default first salesperson will now automatically be set to the user that is signed in.

The beta work order dashboard was not filling the Recipient(s) dropdown with customer emails. Flyntlok will automatically fetch emails associated with the company listed on a sales order. The system will then show the emails in the Recipient(s) dropdown on the "Email Report" page. This will make it faster to email quotes and receipts to customers.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!