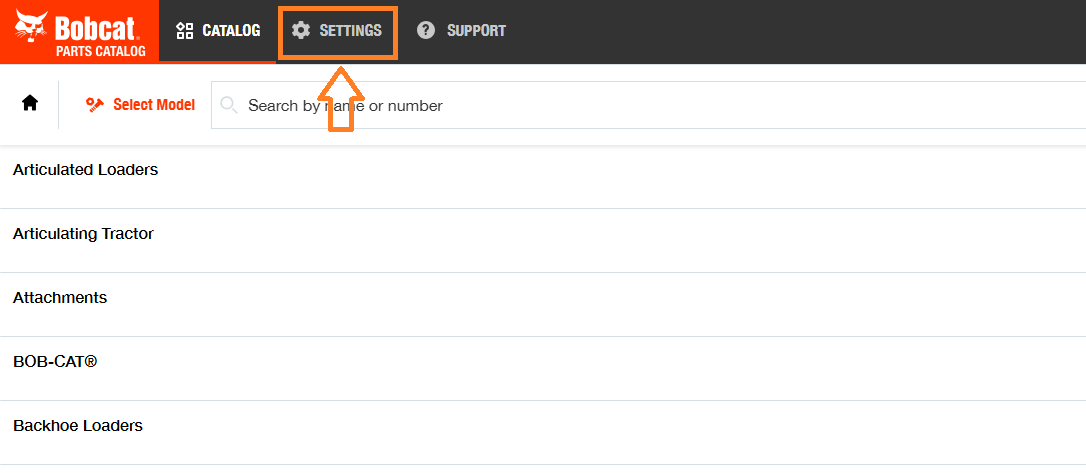

Log in to your Bobcat account and go to Parts Catalog. If your account has access, you should see a "Settings" link at the top navigation bar. Then click on the "DMS Integration" link on the left sidebar.

Feature URLs

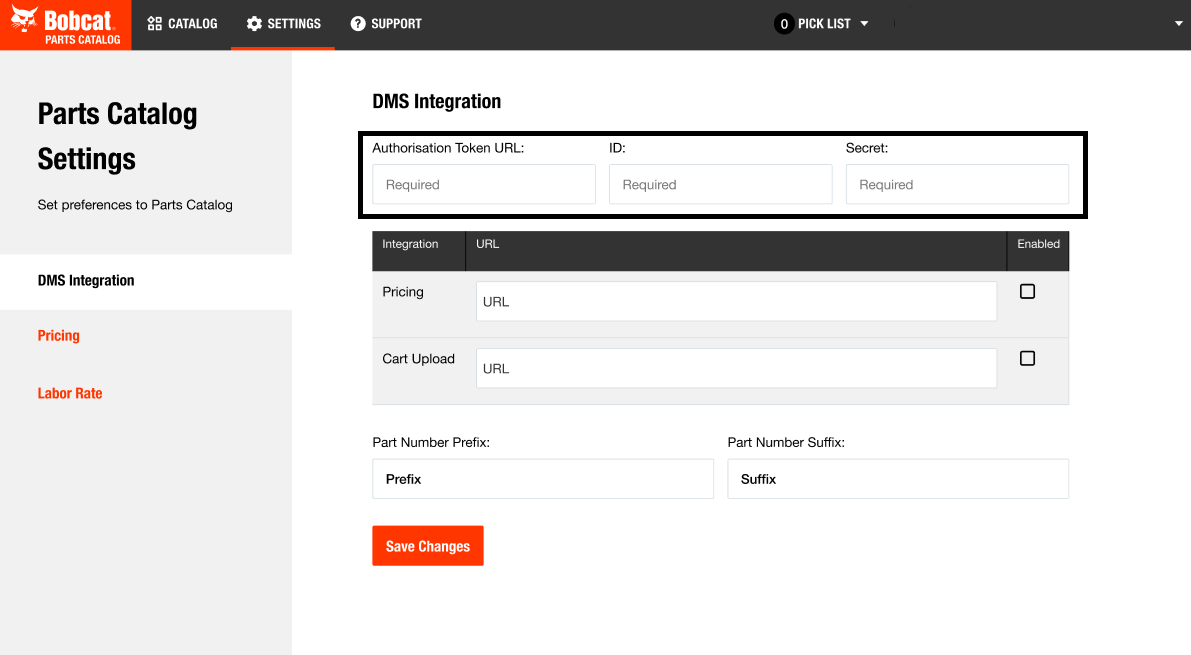

Pricing URL - If you wish to use the Parts Availability feature which provides QOH and Pricing data, enable this and enter this into the "URL" field:

https://flyntlok.com/webhooks/bobcat-opc/parts-availability

Cart Upload URL: If you wish to use the Cart Upload feature which allows you to export a Pick List directly to Flyntlok, enable this and enter this into the "URL" field:

https://flyntlok.com/webhooks/bobcat-opc/pick-list

Authorization

You should see several required inputs near the top of the DMS Integration section. In the next steps, you will use Flyntlok to generate the data to set those fields.

In Flyntlok, access the Bobcat Parts Catalog Settings page. You can access it through the top-right Wrench Icon > Flyntlok > Integrations, then click on "View Bobcat Parts Catalog Settings".

Or access this link directly if you are already logged in to Flyntlok: https://flyntlok.com/rc/integrations/bobcat-opc

Non Alaskans be like: Wait, what?! That’s a thing? Yes, Monday March 31 is Seward’s Day in Alaska and it is an official Flyntlok holiday. However, we recognize that all you folks outside of the 49th state are all going to be working. So we will have a reduced staff that day to manage your questions and to provide help; just understand if we don’t respond quite as quickly as we normally do...

And if you are bored this weekend, you can go read up about William H. Seward and fill your head with fun facts to amaze your lower 49 state or fellow Canadian friends. E.g. Did you know Seward was wounded in an assassination attempt at the exact same time that Booth killed Lincoln? It was part of a plan to slay the three senior members of the Executive Branch. (Spoiler: the assassination plan of Seward failed).

Here at Flyntlok we are not only building the most cutting-edge Dealer Management software, but we also want to act as industry thought leaders. To that end, we encourage you to follow us on LinkedIn and review our periodic blog posts. For example, here is a recent posting about our integration with Avalara for better sales tax management.

If you have a suggestion for a blog post that you think other Flyntlok customers, or the industry in general, might find interesting, please let us know. Drop us a line at sales@flyntlok.com.

Opportunity

Intuit is pushing applications integrated with QuickBooks Online, like good ol' Flyntlok, to upgrade to their newer back-end application interfaces. In order to continue communicating with them, we’re required to update Flyntlok’s QuickBooks accounting integration.

Solution

We took this as an opportunity to upgrade our entire back-end accounting integration services to improve reliability and eliminate some longstanding issues that have been impacting our users. We started to undertake this project at the end of 2024 and it will continue for several months still to come.

The first phase of this project was essentially invisible to you, but we have migrated all of our services to a newer technology and made it compatible with QuickBooks Online’s latest specs. Now, when an accountant hits one of the processing buttons on their QuickBooks Online page, it uses the updated logic. This back-end update is going to allow us to have better automated testing and allow us to make changes much faster. So, while not visible to you as a user, it's going to pay huge dividends for us going forward. We felt like you oughta know.

Additionally, we’ve resolved some long-standing bugs with the process, including where Credit Memos and Refund Receipts sometimes posted even when their associated Journal Entry failed; and Customer Deposits using Gravity credit card fees subtracted the fee from every payment. Those bugs have now been addressed.

Over the coming months we will provide notifications across all accounting-sync processes for failed transactions. We aim to tell you why a transaction failed, what the offending transaction was, and how to fix it. We want you to have the ability to fix issues on your own rather than forcing you to create a support ticket to resolve simple problems. Power to the people! Stay tuned..

Opportunity

John Deere offers an optional, dealer-paid service called Retail Parts Management (RPM) that helps dealers manage their parts inventory. A key tool from RPM is called JDPrism, which is used to manage dealer stock levels. Using JDPrism, RPM can recommend stock orders, special orders, and transfers between dealer store locations based on stocking levels and sales history.

Our John Deere dealers have requested an integration with JDPrism so they can leverage this powerful tool to better manage their inventory and receive suggestions from John Deere.

Solution

We have implemented an integration with JDPrism that allows dealers to better manage their John Deere parts inventory. To drive this integration, your John Deere parts inventory data (e.g. quantity on hand, sales history, etc.) will be uploaded to JDPrism on a regular schedule set by John Deere. Then, you can approve Orders or Transfers within JDPrism that will be ingested into Flyntlok periodically throughout the day (every 15 minutes or so) to create Purchase Orders and Part Transfers.

If you are interested in the JDPrism integration, please reach out to your friendly Flyntlok consultant for assistance.

Opportunity

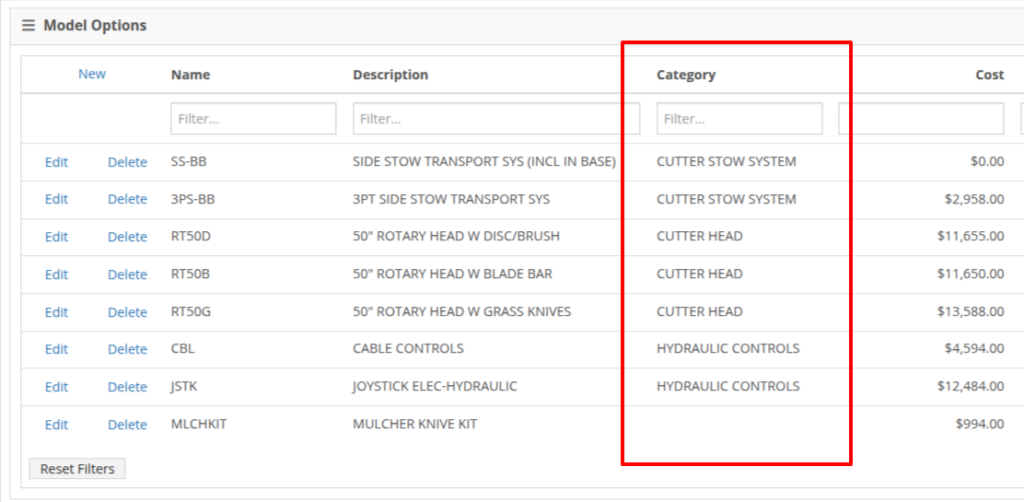

Sales Managers requested the ability to better organize their Model Options. Previously, managing Models with a large number of options could feel a bit overwhelming.

Solution

Our enhancements to Model Options are designed to make managing Model Options easier and more efficient. To simplify this, we’ve introduced two key improvements to the Model Options Editor:

NOTE: This is just the beginning of the “Model Option” fun! The new "Category" field will play a key role in upcoming enhancements to Model Options, including updates to Sales and Purchasing workflows. Stay tuned for more updates!

Opportunity

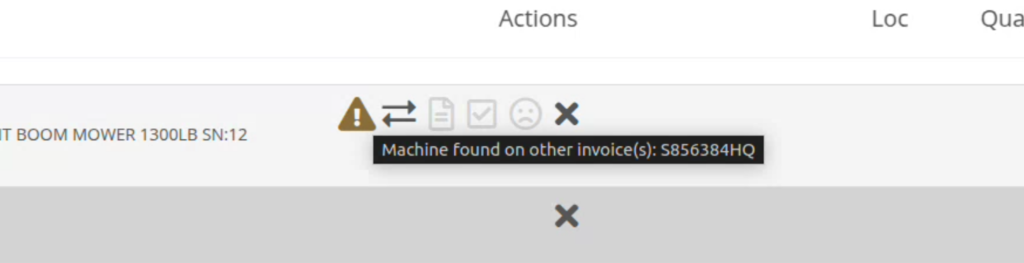

Salespeople shared that knowing about potential Machine sale conflicts earlier in the sales process would be a game-changer. While we already provided warnings during the sale processing stage, we did not show this critical information at any other time during the life of the sale. Selling the same Machine unknowingly could lead to accuracy issues and impact customer satisfaction.

Solution

An indicator icon will now appear on the Machine sale line whenever there’s a potential conflict, such as the same Machine being listed on another Sales Order. This gives you a heads-up before finalizing the sale.

We've also added the same indicator when searching for a Machine to add to a sale. This means you’ll know about potential conflicts before adding the Machine to the order, saving time and avoiding surprises.

Opportunity

Service Managers have asked for greater control over workflow automations, specifically at the Job level within Work Orders. Previously, our automation tools could only update Work Order statuses.

Solution

We've expanded this functionality to include Job-level status updates as well! By automating Job status changes based on key workflow actions, shops that rely on Job-level tracking can reduce manual updates, improve reporting accuracy, and ensure that technicians, parts teams, and service managers stay aligned in real-time. This means fewer bottlenecks, better communication, and faster turnaround times.

New Automation Triggers

You can now configure Work Order Jobs to automatically update their statuses based on the following actions:

Reach out to your friendly Flyntlok consultant for assistance in setting up these new automations!

Opportunity

Service Managers handling cost-of-sale (COS) Work Orders struggle to track the associated customers from the linked invoices, as these details are not visible on the Service Scheduler.

Solution

We have improved the display of the Work Order search results in the Service Scheduler to show the Cost-of-Sale Invoice's customer, making tracking and scheduling more seamless. Additionally, we have enhanced the title of scheduled events in the Service Scheduler when a Work Order is scheduled at the time of creation.

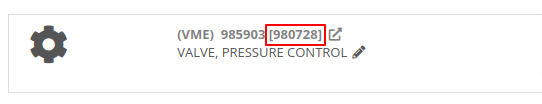

Opportunity

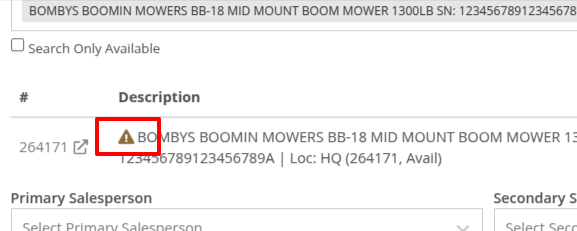

Users managing Cost-of-Sale Work Orders often need to verify the linked Sales Order and associated invoice. Previously, this required navigating back to the Sales Order, leading to inefficiencies and potential tracking issues.

Solution

Cost-of-Sale Work Orders now display the linked invoice directly within the Work Order, allowing users to quickly access relevant details without leaving the page.

Opportunity

Technicians faced challenges identifying machines because the mobile view did not display their descriptions.

Solution

Machine descriptions are now included in the Work Order Search display results on the mobile view, making it easier to identify equipment.

Service Managers have requested that Correction Notes be included on Work Order Estimates to provide more clarity and context when sharing with customers.

Solution

We've added a new setting: "Show Job Correction on Work Order Estimates". When enabled, this setting will include Correction Notes on newly generated estimates. To turn this feature on, go to Flyntlok Settings and find it under the Service section.

Opportunity

Users find adding or locating contacts on the New Work Order page to be cumbersome and occasionally buggy.

Solution

Opportunity

Sales Managers requested an automation that updates Shopify orders when an invoice moves to "Pickup" or "Delivered" statuses in Flyntlok. Previously, Salespeople had to manually update Shopify, which is time-consuming and redundant.

Solution

Flyntlok now automatically updates Shopify orders to reflect "Pickup" and "Delivered" statuses when corresponding invoice updates occur. This eliminates the need for manual intervention, streamlining order management.

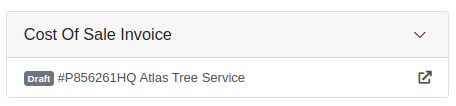

Opportunity

Sales Managers requested a notification for incoming Shopify orders, so that any salesperson that wants or needs to know about such orders will be notified immediately.

Solution

There is now a new notification for orders from Shopify that can be enabled for anyone who wants it.

Opportunity

Users found the reversal process for posted splits confusing, as they would end up in a "Delivered" status if the parent invoice was not also reversed.

Solution

Now, when attempting to reverse a split, a warning will inform users if the parent invoice must be reversed first.

Complaint: Parts Managers had noted that, when attempting to merge parts, sometimes mergeable parts would not show up in the list to be merged.

Correction: Fixed.

Complaint: When using Scan Mode on the Receiving Voucher, scanning a barcode resulted in a "Part Not Found" error, even though the part was listed on the voucher.

Correction: The issue was caused by a leading space in the scanned item number, preventing an exact match. The Scan Mode has been updated to automatically trim leading and trailing spaces from the scanned input.

Complaint: A technician was able to add parts to a Work Order after it had been invoiced, even though no changes should be allowed once the Work Order has been Invoiced.

Correction: Fixed.

Complaint: The total amount on the printed Work Order report was off by one cent compared to the final invoice.

Correction: Fixed the rounding of the estimated tax on the print, ensuring that the total calculation now matches the final invoice.

Complaint: Users were unable to edit the Certificate of Conformance (COC) requirement from the Purchase Order.

Correction: Enabled the COC field to be editable in PO edit mode, allowing users to update the requirement as needed.

Complaint: Sales Managers noted that they would sometimes receive duplicate CRM Leads generated from their marketing site's "Text Us" form.

Correction: Fixed an issue with CRM Text Us widgets where customers were able to inadvertently submit an inquiry multiple times.

Complaint: Managers complained that they were not able to update their Sales Order default footer in Flyntlok Settings.

Correction: Fixed. We have updated this setting to support longer default footer messages.

Complaint: Rental Clerks were unable to load Rental Dashboard without errors.

Correction: Fixed an issue where Rental Dashboard failed to load defaults when store hours were not configured in Rental Settings.

Complaint: Salespeople mentioned that some Sales Order links appeared broken on their CRM Lead Dashboard timeline.

Correction: Fixed. Deleted Sales Orders associated to a CRM Lead will no longer display as a link.

Complaint: Managers complained that when using the "Merge Model" tool, they were unable to find a model by searching its internal ID.

Correction: Fixed. “Merge Model” searcher can now search by internal Model ID.

Complaint: Sales Managers mentioned that when using the Bulk Update action on the Part Price Matrix page, it did not appear to be factoring in Unit Qty when auto-calculating list price. This happened similarly on individual updates via the new Pricing Matrix editor.

Correction: Fixed.

Complaint: Purchasers noted that when reporting an Exception on Part Purchase Orders, the PO status would not update.

Correction: Fixed. PO Status is now automatically refreshed when reporting an Exception on a PO or any of the PO's associated Vouchers.

Complaint: Fleet Managers noted that when printing a Machine “Internal Asset Report”, the Machine's ID appeared to be missing or incorrect.

Correction: Fixed report to show the proper Machine ID.

Complaint: Service Managers complained that when printing a Work Order Worksheet PDF, sometimes the Jobs would be listed out of order.

Correction: Fixed.

Complaint: Salespeople were unable to deliver Invoices because the "Credit Auth" payment type was applied to Multi-Pay Sale.

Correction: Disabled "Credit Auth" payment type in the Multi-Pay workflow to allow invoices to close properly.

Complaint: When updating Work Order Statuses, the updated status would sometimes disappear from existing Work Orders that had that status set.

Correction: Fixed.

February 12th, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity

Users who administer their company’s Shopify store requested that sale prices in Flyntlok for Machines listed on Shopify be reflected there.

Solution

Sales on Machines in Flyntlok are now automatically applied (or unapplied when removed) in Shopify as well. Sale prices are reflected in Shopify with a struck-through price.

Opportunity

Managers mentioned that Machine data coming from their Hitachi telematics integrations were updating Machines that they did not want to be automatically updated.

Solution

For companies with Hitachi telematics enabled, there is now an option to opt out of automatic updates per Machine. To toggle this feature, click on the “Opt Out of Telematics” button found on Machine Dashboard’s “Current Location” section.

Opportunity

Service Managers requested the ability to send email CCs internally when emailing Machine Deficiencies.

Solution

You can now choose to CC others from your company when emailing Machine Deficiencies.

Opportunity

Purchasers who buy Sublet Items will change the sublet cost on Purchase Orders often, but this would also change the Item’s cost for the rest of the system. They requested a behavior change so that the Sublet cost on the Purchase Order would not change the Item’s cost overall, just the cost on the Purchase Order.

Solution

Changing the cost of a Sublet Item on a Purchase Order will no longer update the item’s cost that you see on the Item Dashboard. Cost changes for non-sublet items will still update the item’s cost, which will be reflected on the Item Dashboard.

Complaint: Service Managers reported that Work Orders with multiple Warranty Invoices were displaying only one Invoice in the banner on the Work Order Dashboard once the Work Order had been invoiced.

Correction: Banner now shows all Warranty Invoices.

Complaint: Parts Receivers reported that updating the cost of an Item on Part Purchase Orders did not update the list price of that item as they would expect.

Correction: Fixed.

Complaint: Service Managers reported that Work Orders were scheduled with incorrect times when Scheduled at the same time as the creation of the WO.

Correction: Fixed.

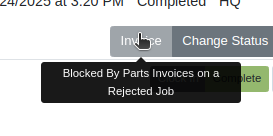

Complaint: Users reported that Work Orders with Internal Parts Orders on rejected jobs would not transition to “Invoice” status. Instead of displaying a message explaining the issue, the invoice button remained active but unresponsive.

Correction: The “Invoice” button is now properly grayed out when invoicing is blocked due to parts on a rejected job. Additionally, a tooltip message will appear, informing users that invoicing is blocked.

Complaint: Users reported that certain parts were incorrectly displaying an “Alternates” indicator on search, even when no alternate parts were available, causing confusion.

Correction: Fixed.

Complaint: Salespeople reported that non-taxable items were being taxed on split invoices.

Correction: Fixed. If an item is non-taxable, it will not be taxed on a split invoice.

Complaint: Receivers reported issues allocating fees on Machine Vouchers; the fees would not be applied as expected if there were machines with a base cost of $0 on the voucher.

Correction: Fixed.

Complaint: Inventory Managers noted that when updating the “Auto-Sync” options for Shopify-connected items, the Item would sometimes not push the changes to their Shopify store.

Correction: Fixed. While editing an item, clicking the “Save” button in the Shopify Settings area will now apply the Auto-Sync settings change without requiring the user to also click on the Item’s main “Save” button.

Complaint: Salespeople reported that they were sometimes unable to Process Sales Orders that contained an Item with a Core.

Correction: Added an indicator to Core items to show when there may not be enough QOH to fulfill the line.

Complaint: Service Writers mentioned that when editing Labor lines on Work Order Dashboard, they would get an error and were unable to save any changes.

Correction: Fixed an issue that caused an error when editing Labor that did not have a “clock out time” set.

Complaint: Salespeople reported that when emailing an invoice to a customer, some characters would appear incorrectly.

Correction: Fixed an issue that caused some special characters and accented letters to appear malformed on Flyntlok-sent emails when viewed in Microsoft Outlook.

Complaint: Service Managers using the Job Calendar Scheduler noticed that the scheduled Technicians were being assigned to the Job, but not the Work Order.

Correction: Fixed. Technicians assigned work from the Job Calendar Scheduler will also be assigned to the Work Order.

Complaint: Managers doing Inventory Counts reported they were unable to edit a count’s quantity if the number was too large, and they would get an error saying invalid quantity.

Correction: Fixed.

Complaint: When updating the Start and End date of a scheduled Work Order in the Service Scheduler, the changes would sometimes fail to persist. This occurred because there was no validation to ensure the Start date was earlier than the End date.

Correction: Added validation to ensure the Start date always precedes the End date. (Feels like we fixed something similar last release, don’t it? Well, we did. You are a careful reader if you noticed that.)

Complaint: Sometimes the “Date Start” and “Date End” in the “All Work Orders” report were not reflecting the dates set on the Work Order correctly and were off by one day.

Correction: Fixed.

Complaint: Users were unable to invoice Work Orders when there are Rejected Parts Invoices on a Rejected Job. Previously, they were able to do this, but the new restriction has unintentionally blocked this workflow.

Correction: Fixed.

Complaint: Machine Purchase Order Vouchers were sometimes posting to QuickBooks with a negative amount when the Voucher total added up to $0.

Correction: Fixed. This was due to a rounding error, which calculated the sum to be a very small negative number instead of exactly $0.

February 12th, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity

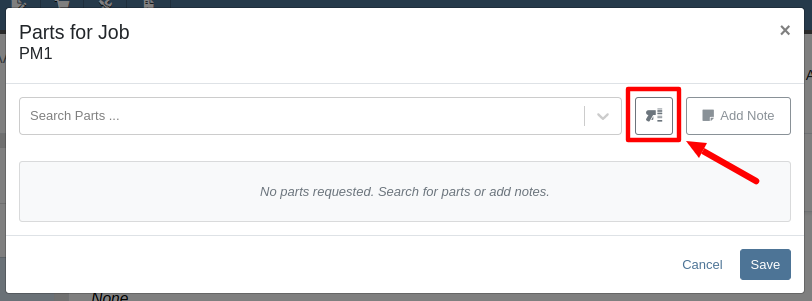

Searching for parts can be oh-so-tedious. Techs have asked for the ability to scan a barcode to add parts to a job.

Solution

When you’re requesting Parts for a Work Order, you can now click a button to enter “Scan Mode” which lets you use a barcode scanner to add Parts more quickly.

Opportunity

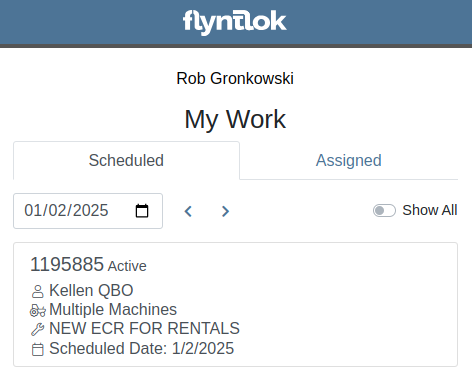

Technicians requested an improved way to view their scheduled work orders on the mobile view.

Solution

The "My Work" page on the mobile view has been redesigned to provide a more user-friendly experience. If the "Show Technicians Scheduled Work" setting is enabled, Technicians can now:

Opportunity

Purchasers wanted a more streamlined way to close out a Machine Purchase Order after receiving it fully on a Voucher. Previously, they had to first close the Voucher, then find its associated PO and close it separately.

Solution

When completing a Machine Receiving Voucher that moves any of its associated POs to "Received" status, users now have the option to immediately close the PO. When applicable, this prompt will show up after clicking the Complete Voucher button:

Opportunity

Managing pre-delivery inspection (PDI) costs efficiently has been a challenge, especially for dealers handling high-volume orders. While some equipment dealers often use work orders to capitalize PDI costs against units, this approach is too time-consuming and inefficient when managing numerous smaller units.

The existing PDI field on Machine Receiving Vouchers didn’t allocate costs to units when posting, creating additional manual effort and inefficiencies.

Solution

To streamline PDI cost management, we've introduced a new feature that allows you to allocate PDI costs directly on machine Receiving Vouchers. This update simplifies workflows and ensures more accurate financial reporting.

Key Enhancements:

Configuration:

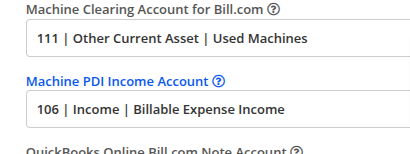

To set the PDI account, navigate to Flyntlok Settings and configure the account as shown below:

Opportunity

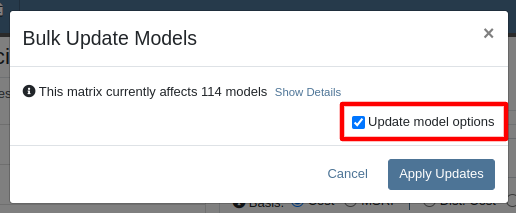

Managers requested the ability to update Model Options Pricing in bulk to align with the model pricing matrix.

Solution

A new feature in the “Bulk Model Update” allows managers to update Model Options Pricing automatically when running a Pricing Matrix against a Model. This ensures that all associated Options are priced correctly based on the latest Matrix.

Opportunity

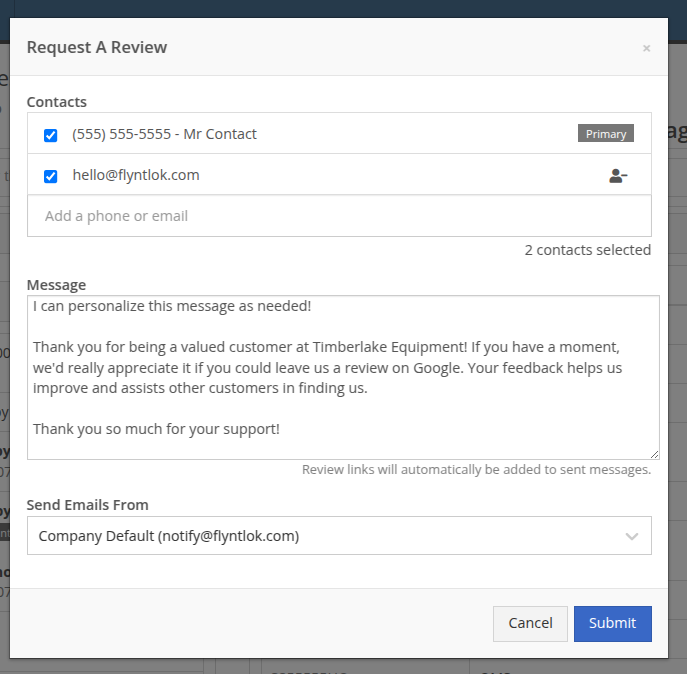

Salespeople wanted a way to personalize the message sent to their customers when sending them a request for a Google or Facebook review. While we previously supported adding text to a Review Request, a Salesperson's customer was sent the same message template that could not be edited.

Solution

Administrators can now configure the default message by navigating to Flyntlok Settings -> CRM Settings -> General -> “Request A Review” Message,

This default message will prefill the message body when requesting a review. You can modify the message as needed before sending it.

The message will be sent to the customer with the review links included. Here is an example message shown as a text and an email:

Note: If this is not configured, a basic message template will be used instead.

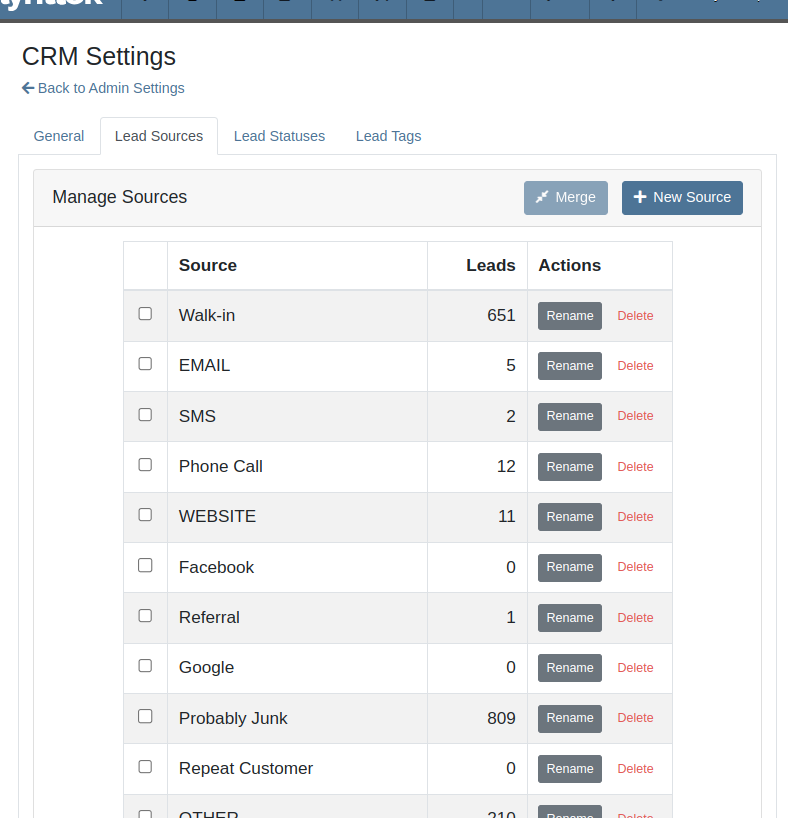

Opportunity

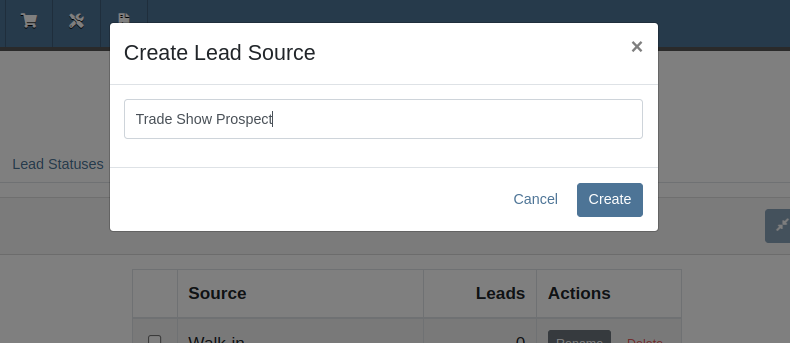

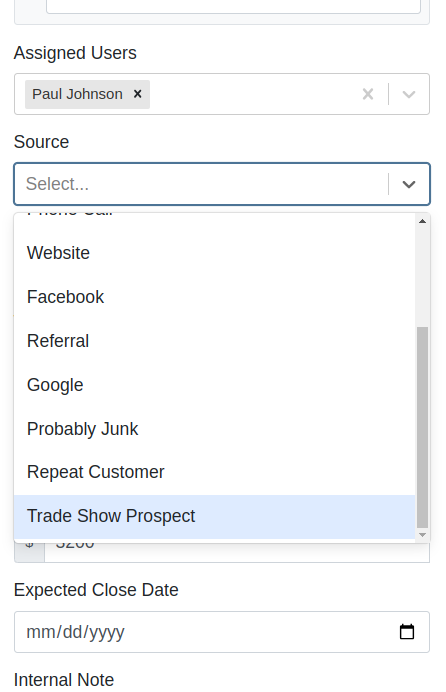

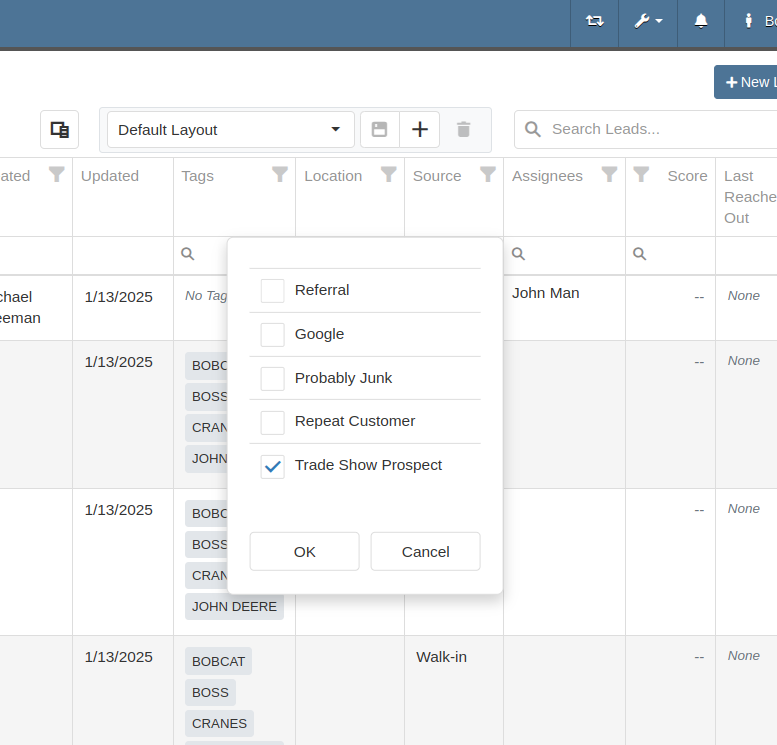

Sales Managers needed greater flexibility in customizing “Lead Sources” within their CRM systems. This level of customization allows for more accurate and insightful reporting while better aligning lead tracking with the unique needs of their business. Previously, the lead sources were not customizable, limiting managers' ability to adapt the system to their specific workflows. (Or they had to call us and ask us to hard code a value for them.)

Solution

To address this, we’ve enhanced the CRM “Lead Sources” flexibility to enable full customization. This empowers sales teams to better manage and refine their “Lead Sources”, resulting in improved reporting and streamlined lead management. And more customers!

Key Enhancements:

With this update, your CRM system becomes more adaptable to your business, ensuring that lead management is precise, efficient, and tailored to your needs.

Complaint: Salespeople mentioned that a Contact’s Tags would not show on the Customer Dashboard if the Contact was a Primary or Accounting Contact.

Correction: Fixed.

Complaint: Users (well, Wayne) noted that when trying to access a Vendor's website URL via Vendor Dashboard, the link would not work if it didn’t start with “http://” or “https://”.

Correction: Fixed. The link now supports more URL formats.

Complaint: Accountants noted that while editing a Machine, the Accounting Transactions preview would sometimes display the wrong accounts.

Correction: Fixed an issue where, on depreciating Machines, the Accounting Transactions preview would incorrectly display the Vendor account instead of the account that was set on the Machine. This was a visual-only bug and did not have any direct effect on accounting data.

Complaint: Inventory managers mentioned that they were sometimes unable to delete Vouchers from a Part Purchase Order.

Correction: Fixed.

January 1st, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

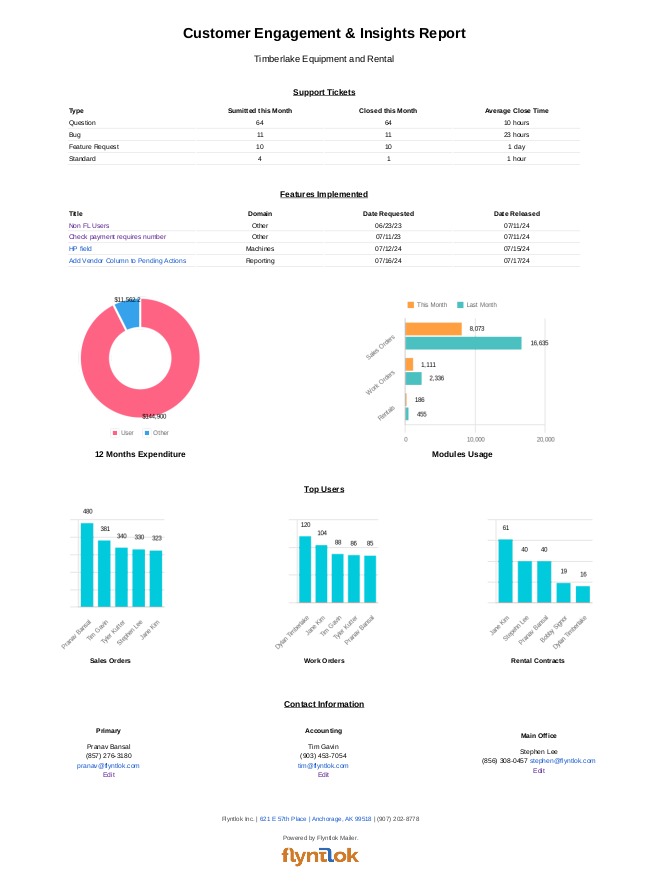

We will start sending all of our Flyntlok customers a personalized report at the end of every month that will provide a comprehensive overview of your company's engagement with Flyntlok. This report will help identify opportunities for improvement and increase transparency. It will include the following information:

Admins will be able to set up the recipient email addresses for these reports on the new Account Settings page (more below).

The first scheduled delivery of this report will be on August 31. Be on the lookout!

Opportunity

Stihl has released a new major update to their integration, which provides better data about Stihl products.

Solution

We have upgraded our integration to the latest version offered by Stihl so that we can show the most up-to-date information possible. We have updated the widget on the machine dashboard to reflect the newest Stihl data; additionally, we have added the same information to the widget on the item dashboard.

Opportunity

Dealers who participate in the Bobcat Parts Trading Network have requested the ability to send a nightly CSV with part availability data to Bobcat automatically.

Solution

On a nightly basis, Flyntlok can now aggregate the required data into a CSV and send it to Bobcat. If you wish to enable this feature for your dealership, please contact your friendly Flyntlok consultant to discuss exactly which data you would like sent to Bobcat.

Opportunity

Managers have requested easy access to vendor information from the "Pending Actions" view.

Solution

Added a clickable link to the Item’s vendor at the end of each message on the "Pending Actions" view.

Opportunity

Service managers have requested easy access to the engine make field when creating a new machine on the Work Order Dashboard.

Solution

We have added the “Engine Make” field to the “Advanced” tab of the Work Order Dashboard's new Machine form.

Opportunity

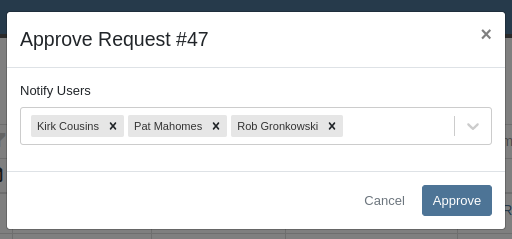

Service Managers have requested the ability to notify multiple users when a Service Request is approved or rejected.

Solution

Added an “Additional Users To Notify” field to the Service Request creation form that allows you to select users to notify. Service Managers can also edit this list when approving or rejecting a Service Request.

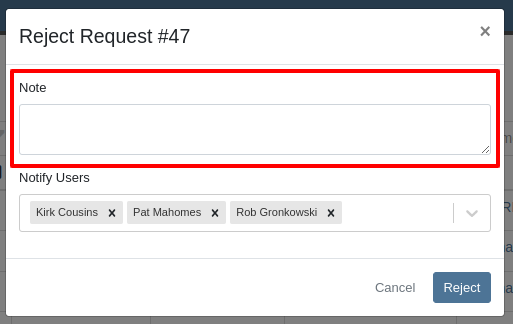

Opportunity

Service Managers have requested the ability to provide the reason a Service Request was approved or rejected.

Solution

Added a “Note” field to the form for Approval or Rejection of the Service Request.

This note is shown on any notifications sent when approving or rejecting the Service Request.

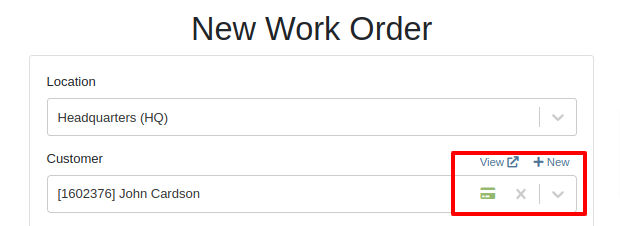

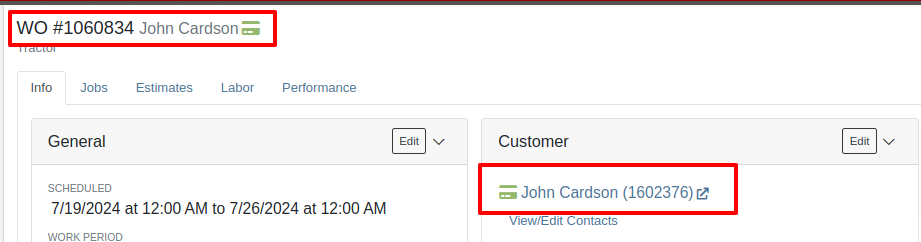

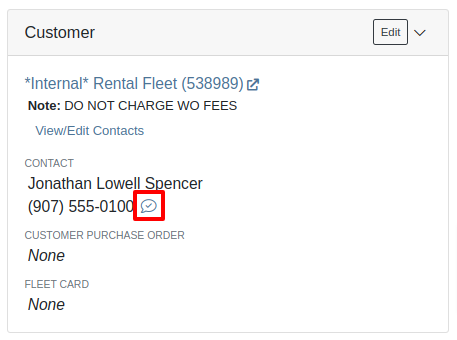

Opportunity

Service Managers requested an indicator for whether or not a Customer has credit cards on file when creating and viewing Work Orders.

Solution

A credit card icon will appear on the New Work Order form and the Work Order Dashboard if a Customer has any cards on file.

Opportunity

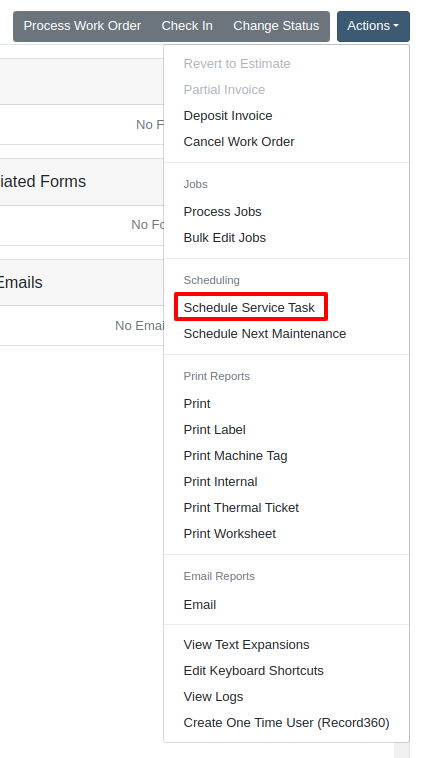

Service Managers have requested the ability to create a scheduled task through existing Work Orders.

Solution

We have added an action to the Work Order “Actions” menu to create a scheduled task from the existing work order.

Opportunity

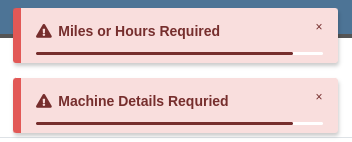

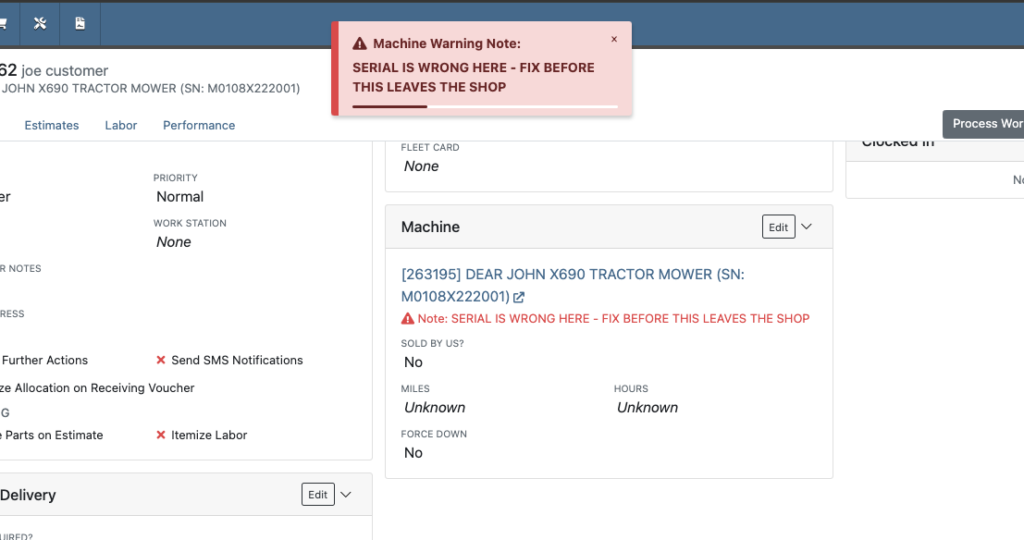

Service Departments reported that Machine warnings on Work Orders were obstructing some forms, hindering technicians.

Solution

We have made the Machine Warnings dismissible and added a warning indicator to the header of the Work Order Dashboard. When you hover over the badge, it displays the same warnings, ensuring that the interface remains clear and functional while still providing easy access to those important warnings.

Opportunity

Salespeople asked for the Item Number 2 to be visible on Part lines on Sales Orders and on Sales Order printouts. Item Number 2 is an additional internal part number used for reference purposes.

Solution

Added a setting to display Item Number 2 on the Point of Sale and on the Sales Order printout.

To enable the feature follow these steps:

Opportunity

Managers have requested the ability to limit which users can modify Invoice settings from the Point of Sale.

Solution

A new permission has been added around the “Settings” button on the Invoice page. Administrators can configure this permission by navigating to the Access Control page. The new permission is named “Enable POS Settings” under the Point of Sale section.

Opportunity

It has been requested that Reversed and Deleted multi-pay Sales Orders remove the payment lines generated on the other linked Sales Orders.

Solution

We have added functionality that reverses invoices paid on a multi-pay invoice if the latter is reversed. Additionally, deleting a line on a multi-pay invoice or deleting the invoice entirely will remove the payment line from any invoices previously paid on the multi-pay invoice.

Opportunity

Sales and Service Users have requested the ability to quickly view if their Customer Contact prefers to be contacted via SMS. This improves communication with Customers by reducing the potential of accidentally reaching out to them using the wrong method of contact.

Solution

New indicators have been added if a selected contact has "SMS Notify" enabled. On the Work Order Dashboard, it will show up next to the Contact's phone number with a "Text Allowed" indicator. On Sales Order pages, it will appear as a badge in the bottom right.

Opportunity

Managers have requested the ability to prevent automatic dismissal of the “Customer Note” popup that is on Customer Dashboard, Sales Order, Work Order Dashboard, and Rental Dashboard.

Solution

Added a setting to prevent automatic dismissal of the customer notes.

To enable the feature follow these steps:

Opportunity

Managers have requested the ability to make a reason for creating a customer a required field.

Solution

We have added a setting that will make the reason for creating a customer a required field.

To enable the feature follow these steps:

Opportunity

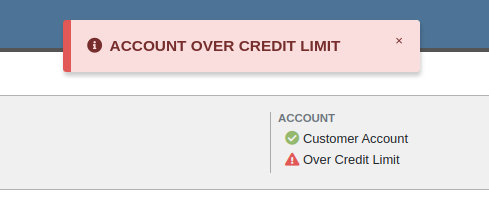

Rental Managers have requested the ability to know when a Customer has exceeded their Account Credit Limit before creating a new Rental Contract.

Solution

We have implemented warnings on Rental Creation that will show when a Customer's Account is over their credit limit.

Opportunity

Managers requested the ability to indicate when a machine has been stolen.

Solution

You can now indicate a Machine has been stolen from the Machine Dashboard by selecting "Report Stolen" from the Actions menu. If you recover a Machine that was stolen, select "Report Recovered" from the Actions menu. Additionally, there is a red warning banner across the top of the page for Machines that have been reported stolen.

Opportunity

Parts Managers requested that the Manufacturer Part Number be displayed on the Parts Purchase Order printout.

Solution

Added a new setting to display the Manufacturer Part Number on the Parts Purchase Order printout.

To enable the feature follow these steps:

Complaint: Parts Managers mentioned that sometimes when loading Item Dashboards for John Deere parts, the additional information pulled from John Deere would not load.

Correction: Fixed.

Complaint: Service Managers pointed out that the layout on the Job Level Service Scheduler was not being saved.

Correction: Fixed.

Complaint: Purchasers using MRP noted that attached Drawings on Parts were not being included when emailing a Purchase Order.

Correction: Fixed.

Complaint: Service Managers noted that editing and saving a Work Order on an iPad would sometimes cause an invalid date format error on correct dates.

Correction: Fixed.

Complaint: Sales Managers reported that invoices marked as paid in QuickBooks Online were not reflecting as unpaid after direct changes were made to the QuickBooks Online data.

Correction: Fixed.

Complaint: Managers pointed out that machines that were created through the “New Machine” page were not being created with the correct model.

Correction: Fixed.

Complaint: Technicians reported that when uploading files on the Work Order Dashboard they were receiving an “Upload Failed” error.

Correction: We have added a notification when files queued to be upload are over the total file size limit.

Complaint: Service Managers reported that SMS conversations with only outbound messages were not showing in the Activity tab on Work Orders.

Correction: Fixed.

Complaint: Service Managers reported an issue with the "Display Detailed Subtotal Breakdown on Report" setting. When this setting was enabled, labor subtotals on Invoices and Quotes for Work Orders were not calculated correctly if the Work Order included Jobs billed by hours.

Correction: Fixed

Complaint: Managers reported that when the user preference for opening a search in a new tab was enabled, the old search query persisted in the search bar on the original tab.

Correction: Fixed

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity

Bobcat dealers expressed a need to access real-time inventory data within Bobcat OPC from Flyntlok and to efficiently manage pick lists created within OPC between the two systems.

Solution

To address this need, we have integrated Bobcat OPC with Flyntlok, providing two key capabilities:

Real-time Inventory Access

Dealers can now view inventory details from Flyntylok such as bin locations, quantities on hand (QOH), quantities on order (O/O), and pricing directly within the Bobcat OPC. To view the inventory details of the parts within the Bobcat OPC go to “Parts Catalog” and select a part you want to view. The opened modal will include the “DMS Availability” section populated with inventory data from Flyntlok.

The inventory data can also be viewed from within the pick list on the Bobcat OPC.

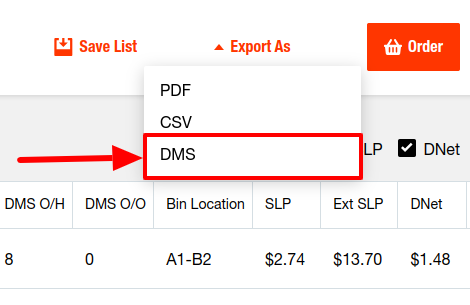

Pick lists Export

Dealers can export pick lists created in Bobcat OPC to Flyntlok, allowing for easy creation of draft Sales Orders or Internal Parts Orders. To export a pick list from Bobcat OPC to Flyntlok, while in the pick list on Bobcat OPC, click “Export As” and select “DMS” from the dropdown.

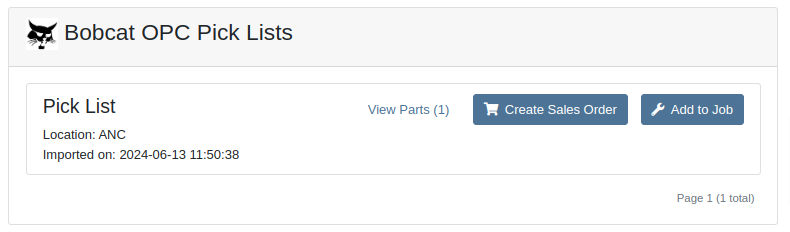

To view the exported pick lists back in Flyntlok, open the left sidebar, navigate to the “Parts” section, and click on the “Bobcat OPC Pick List” link.

On this page, you can view the list of parts on the pick list by clicking on the “View Parts” button.

To create a draft Sales Order, click the “Create Sales Order” button and follow the prompt.

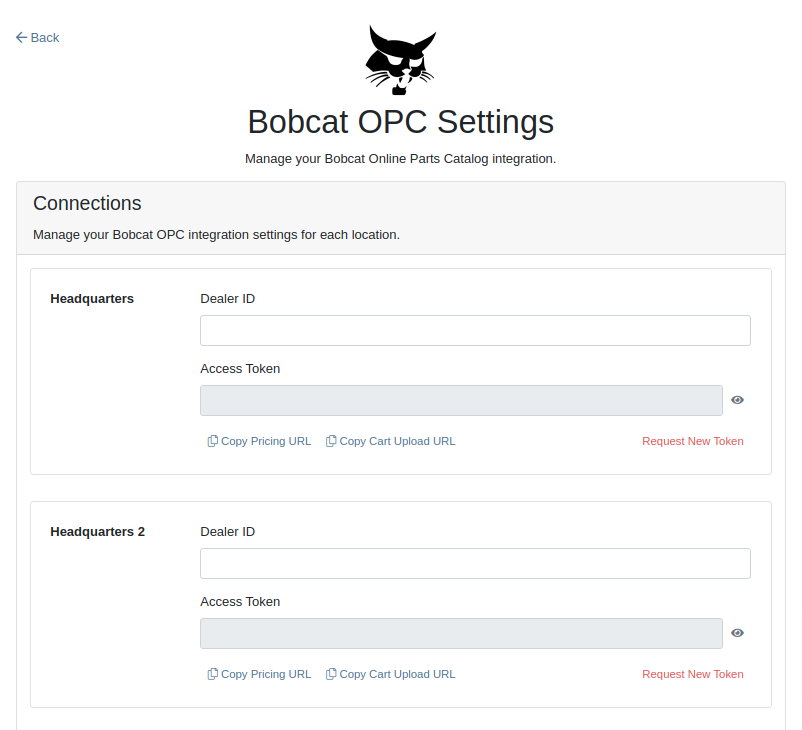

Integration Setup

To connect Bobcat OPC to Flyntlok follow these steps:

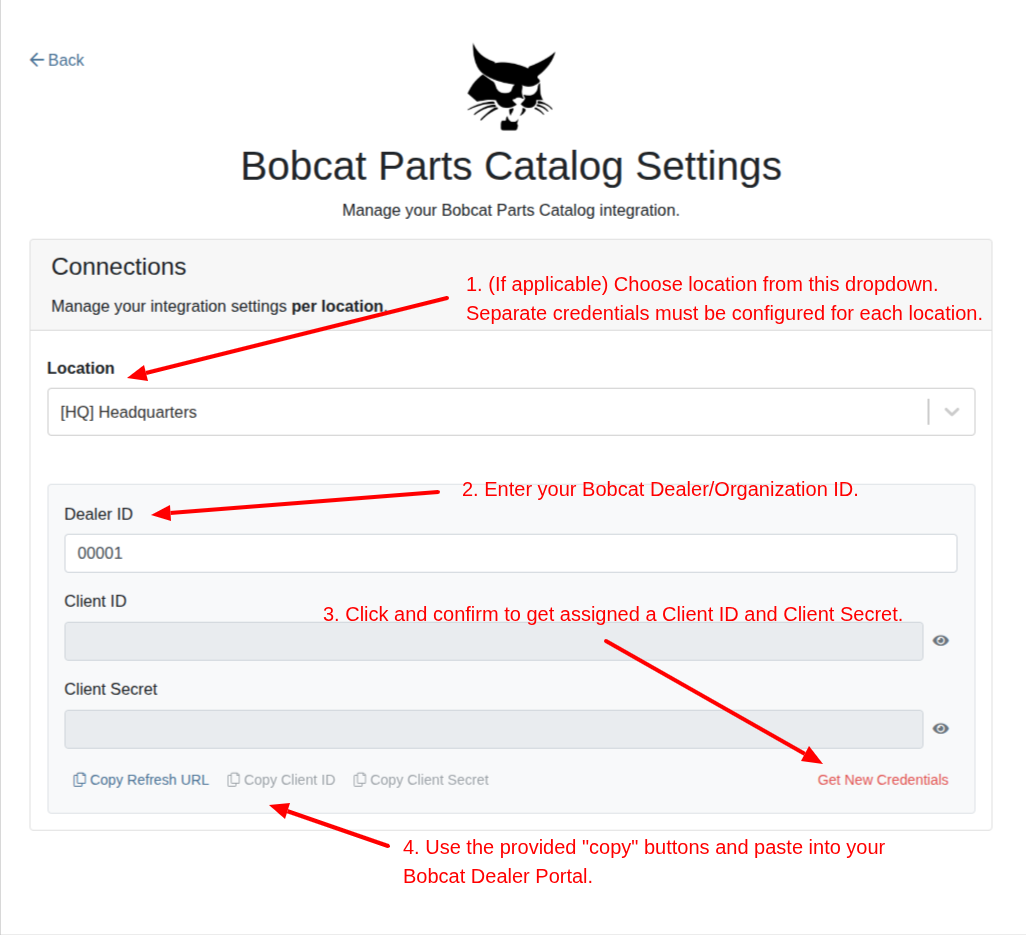

1. Access the Integrations Page within Flyntlok

2. Choose the location you want to connect to Bobcat OPC.

3. Generate token

4. Click on the “Copy Pricing URL” button to copy the Pricing URL.

5. Click on the “Copy Cart Upload URL” button to copy the Cart Upload URL.

6. Log into your Bobcat Account at https://dealer.bobcat.com/.

7. Click on “Bobcat Parts” under the “Parts” section.

8. Select Organization/Location. Use the location for the token you generated in step 3.

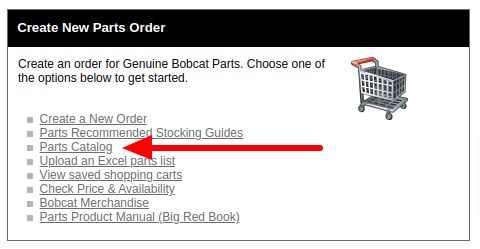

9. Under the “Create New Parts Order” section, click on the “Part Catalog” link.

/images/image9.png)

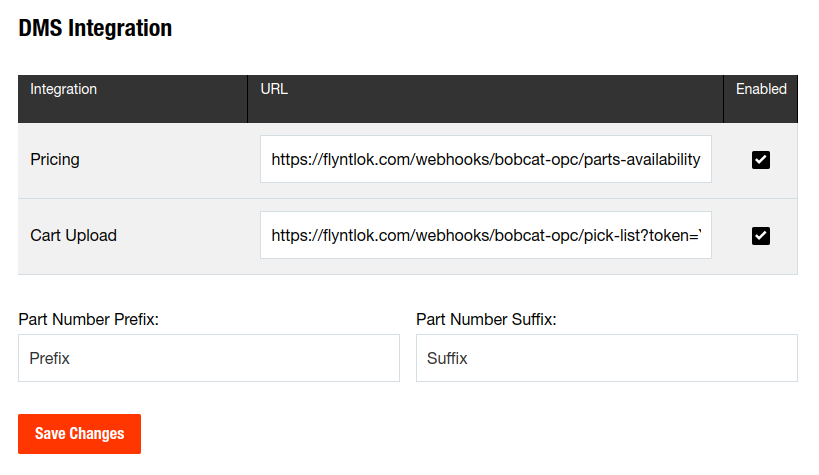

10. Open the “Settings” in Bobcat OPC and navigate to the "DMS Integration" section.

11. Provide the URL from step 4 to the “Pricing” field and enable it.

12. Provide the URL from step 5 to the “Cart Upload” field and enable it.

13. Click on the “Save Changes” button to persist your settings.

14. Repeat steps from 2 to 13 for each location you want to connect to Bobcat OPC.

Opportunity

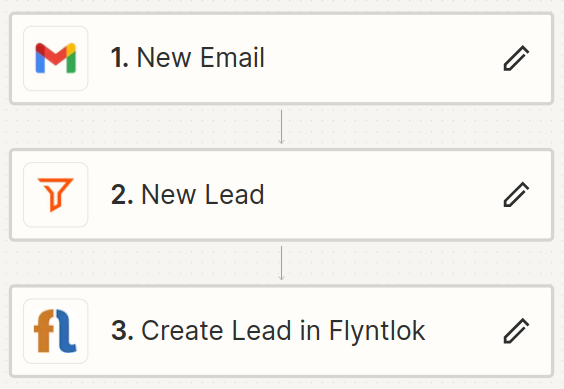

Salespeople, who make use of the automated workflow tool Zapier, have expressed an interest in automating the process of lead creation in Flyntlok by integrating these two wicked cool products.

Solution

To address this need, an app was created in Zapier that integrates with Flyntlok. This app allows users to automate the creation of leads in Flyntlok through various triggers and actions within Zapier.

The following fields are exposed to Zapier via our interface:

Contact your friendly Flyntlok consultant if you would like to integrate us with your Zapier implementation.

Opportunity: Salespeople requested the ability to see the quantity on hand (QOH) directly on a Quote. Currently, users must approve or modify the quote to view QOH, leading to potential miscommunication about stock availability.

Solution: We added the display of QOH on the item lines within the Quote. This change will enable salespeople to accurately inform customers about stock availability without needing to approve or modify the quote.

Opportunity: Sales Managers have requested the ability to apply discounts to items based on their original list price, not the current displayed price. Otherwise, if the customer already has a discount in place, this would apply a discount to a discount (which is awesome for your customers, but not for you!).

Solution: Flyntlok introduced an option to apply discounts to each line item based on their original list price, ensuring each discount is calculated correctly from the list price rather than compounding discounts. This option is available only if the tenant is configured to calculate discounts line-by-line.

The "Apply Discount" form will now include two options for discount application:

Opportunity: Salespeople requested that when processing a Sales Order for an “Account Customer”, they would like to be able to more easily track if a signature had been collected on a Sales Order.

Solution: We have introduced a new option to display a warning when attempting to process a Sales Order. This prompt will show up when clicking on "Apply Payment & Process" if the Customer is an Account Customer, and their signature has not yet been collected.

It will also show a message by the Process button:

![]()

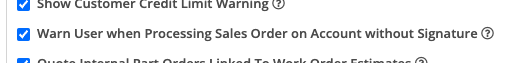

The warnings can be enabled via the Wrench Icon -> Flyntlok Settings

To further improve visibility, we have added a "Signed" badge at the bottom of the page. This feature is enabled for all standard Sales Orders.

Opportunity: Salespeople requested support for our more streamlined “Pay & Process” workflow when requesting payments via Text-2-Pay.

Solution: You can now select “Initiate Payment & Process” when requesting payments via Text-2-Pay.

Opportunity: Service Managers have requested the ability to copy files from one Work Order or Job to another, especially when dealing with Warranty Work Orders, which might be split off from the original Work Order or onto new Jobs.

Solution: We have introduced a dialogue box that allows users to copy both Work Order-level files and Job-level files to other Work Orders and Jobs as desired.

Click on the transfer icon on the file line:

To transfer a file from one Job to another the form requires the user to select a Work Order and a Job. Users also have an option to keep the original file.

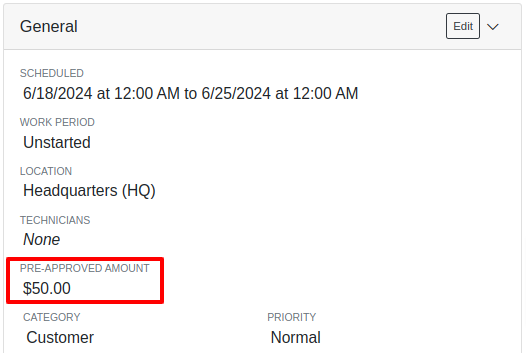

Opportunity: Service Managers requested the ability to set a customer-pre-approved dollar amount on a work order and to be informed when this amount is exceeded by the projected or actual cost of the work order.

Solution: Users can now choose to apply a work order pre-approved amount when creating a work order.

Once on the work order dashboard, this will be visible in General section of the page. It can also be edited here.

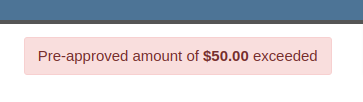

If, for any reason, the actual or projected cost of the work order exceeds this amount, a red banner will appear on the top of the work order dashboard.

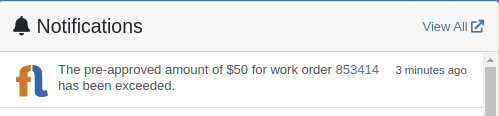

Anyone who is signed up to be notified when this happens will receive a notification.

Once the costs are equal to or below the pre-approved amount, the banner will disappear.

Additionally, users can set a default pre-approved amount on the customer edit page.

This amount will be automatically applied to work orders for this customer unless it is overridden at the time of creation.

Opportunity: Receiving Managers requested that the “Responsible Locations” of machines automatically update when the location on a Machine Receiving Voucher is changed.

Solution: Flyntlok introduced a prompt that appears when the location on a Machine Receiving Voucher is modified. This prompt asks users if they want to update the physical locations of the machines to match the updated location on the voucher.

Opportunity: Salespeople requested the ability to view and edit a Machine's comments from the mobile view.

Solution: We now show the Machine comments on our Mobile Machine Dashboard. It is editable by clicking "Edit" on the page.

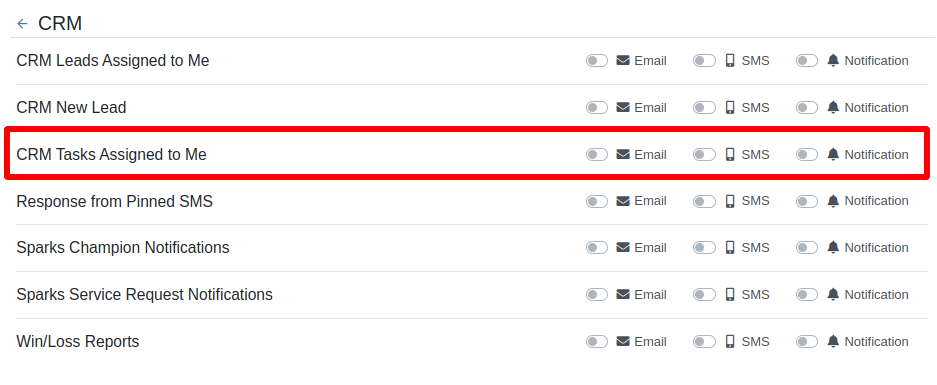

Opportunity: Sales Managers expressed the need for Task related notifications so that users are made aware when a task has been assigned to them.

Solution: Users are now able to receive notifications when they are assigned to a Task, either as the primary or secondary person on the task.

How to Enable Notifications:

Complaint: When printing out or emailing a Work Order the tax amount is not included in the total.

Correction: Fixed.

Complaint: Users reported errors when an Item was set as a Kit sub-item of itself.

Correction: We no longer allow a user to set an Item that is a Kit to be its own sub-item. Waaay too circular…

Complaint: Users reported not being able to apply an above-cost discount to some parts orders.

Correction: Fixed.

Complaint: Users reported that processing a Job that didn’t have any Parts Orders would not mark the job as “Approved”.

Correction: Fixed.

Complaint: Users reported that if you clicked into the Quantity or Fulfilled Quantity fields on the Point of Sale, the cursor would get placed at the end of the number. So if you wanted to change the value, it required that you highlight/select the whole field value first. This issue was both error prone and required extra clicks.

Correction: Fixed. If you click into either of the Quantity fields, we highlight/select the existing value so that if you type in a new value it will overwrite the previous value.

Complaint: Users reported that all Flyntlok journal entries were taking a very long time to process.

Correction: Fixed.

Complaint: Users reported that the incoming call page would crash when receiving calls from some numbers.

Correction: Fixed.

Complaint: Salespeople reported that they would accidentally change the payment amount with the mouse scroller.

Correction: Scrolling with the mouse in the payment field has been disabled.

Complaint: After accepting a Quote, users reported seeing the cost of the Quote’s Model lines change.

Correction: Fixed.

Complaint: Users reported being shown non-sellable machines when associating machines to model lines on the Point of Sale.

Correction: Fixed.

Complaint: Users reported discount structures not being correctly applied to Kits on the Point of Sale.

Correction: Fixed.

Complaint: When editing an Item Purchase Order, a shipping method would be chosen by default. However, users could not change the default that was being selected, and they may not have realized a shipping method was being chosen automatically.

Correction: Fixed. The shipping method selector now displays a prompt to select a shipping method if one is not set, making it more obvious when a shipping method has not been chosen.

Complaint: Users, particularly those in the Northeast of the US, but ultimately any real basketball fan, have complained about the fact that the Boston Celtics have not won the championship since 2008. This has been particularly frustrating some years because they clearly had the better team, especially in 2023.

Correction: Fixed. Flyntlok made sure that the most talented NBA team in recent history (probably since '86 Celts) won the championship this year in an epic manner and clearly illustrated to all of North America that they are the best team in the league. Our Boston office is currently coordinating the Duck Boat parade with city officials.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity

Salespeople have requested more effective filtering in the SMS Inbox to help them better respond to Customers in a timely fashion. Additionally, they requested more information be shown about a conversation to help them understand what a Customer may be asking about.

Solution

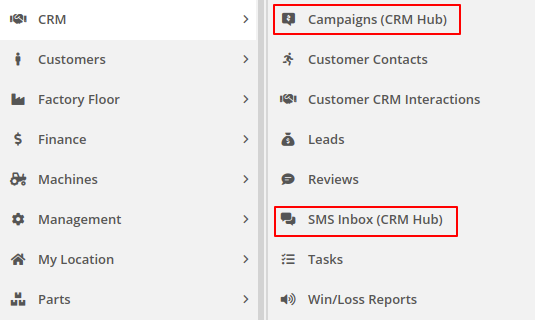

First, we have split what was previously the "CRM Hub" into 2 pages: the SMS Inbox and Campaigns. You can find both in the CRM section of the sidebar as “SMS Inbox (CRM Hub)” and “Campaigns (CRM Hub).”

In the SMS Inbox, open the updated Filters section and you’ll find several new options to narrow down what conversations you’re viewing. Filters within the new “Sent message about'' section allows you to find conversations with messages sent from elsewhere in Flyntlok. For example, "Campaign" lets you find conversations containing messages from a specific campaign and "Customer" lets you find conversations with messages sent from a specific customer’s dashboard. Invoice, Lead, Rental Contract, and Work Order allow you to only see conversations with messages sent from any of the indicated pages.

We’ve also added 4 more general filters to help limit the number of Conversations shown to you:

SMS messages sent from the following pages will now be marked in a conversation to provide a better idea of what that conversation is about:

You can click the link to view the page that message was sent from.

Opportunity

Salespeople have expressed interest in being able to see more data associated with a phone number when a new call comes in, which will allow them to have more context upfront before they decide on a course of action.

Solution

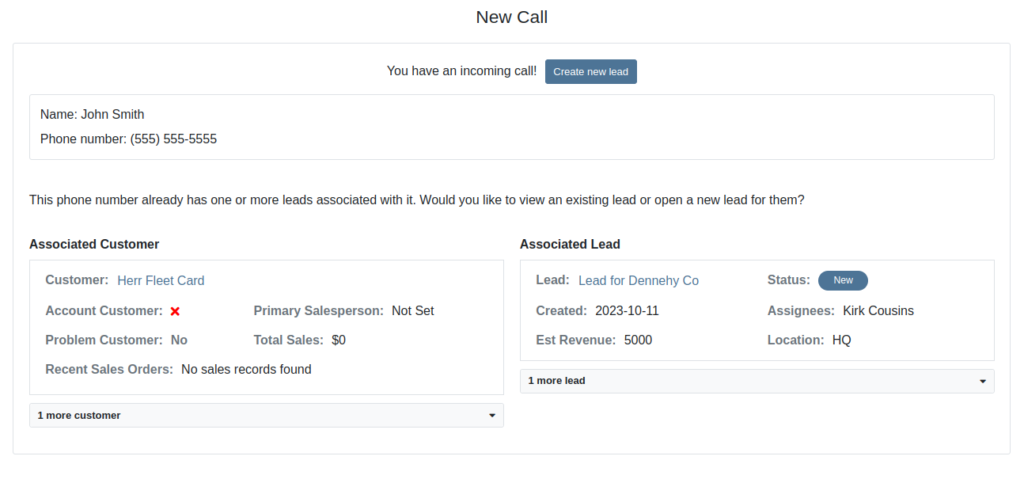

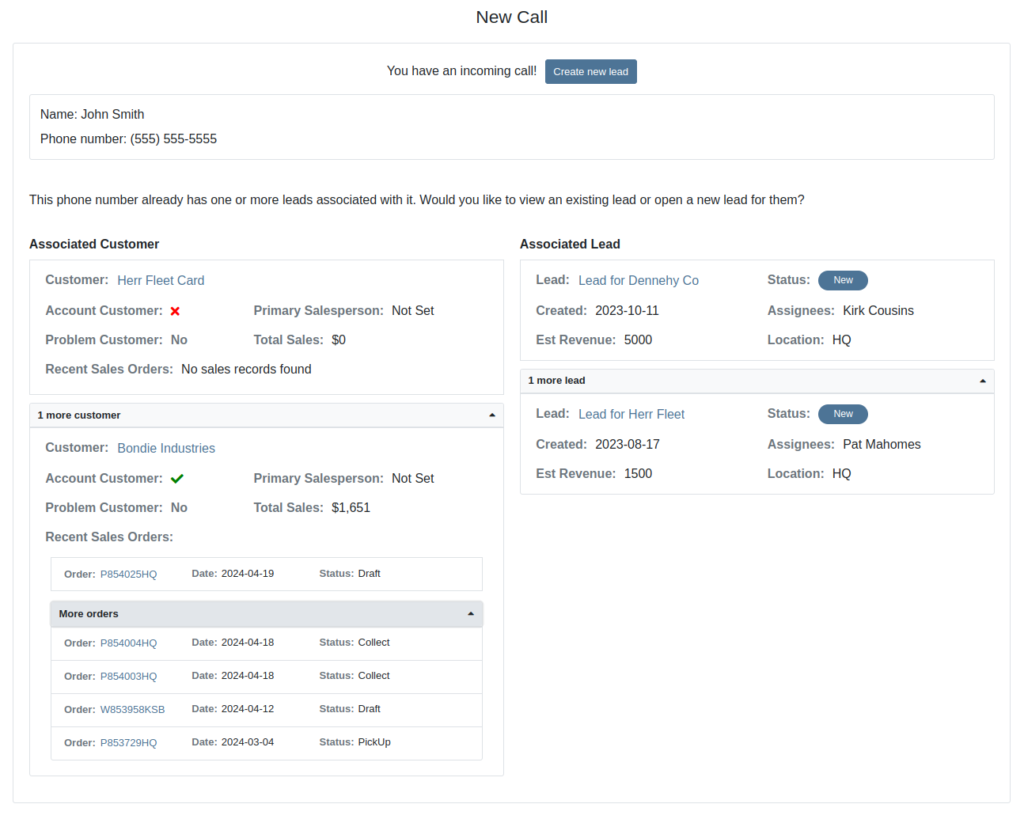

We have extended the capability of our integration with the RingCentral desktop application. We have an updated URL that will support the ‘name’ parameter, and can be entered into RingCentral’s settings under the ‘Manage external apps or URLs for incoming calls’ section. The new URL is - “https://flyntlok.com/ajax/phoneCall?phone=%E&name=%N”. Now when a phone call comes in, a new tab will open in Flyntlok that will display a dashboard with centralized information about any leads or customers associated with that phone number.

The “New Call” page will show the phone number and name of the caller at the top of the page as passed on from RingCentral. If a phone number has been associated with any customer in the past, the most recent actions related to the customer will show up in the Associated Customer Card, along with a link to the Customer Dashboard. If more than one customer is associated with this phone number, information about those other customers will be shown in a collapsible list below the primary Customer Card. Leads associated with the phone number will also show up in a similar manner.

Users will be able to choose to open any of the customers or leads associated with the phone number to continue working with the existing item, or they can create a new lead by clicking on the “Create New Lead” button at the top of the page.

The Incoming Call Page after expanding the collapsible data elements.

Opportunity: Sales Managers have requested the ability to attach images to CRM Campaigns. Including a photo or file with a Campaign would increase the attractiveness of a message and could result in a higher conversion rate for potential sales.

Solution: We have updated CRM Campaigns to support file attachments. Users can attach a file when creating or editing a Campaign. A full preview of the text and attachment can be reviewed before and after sending.

Opportunity

Salespeople have expressed a need to request signatures from customers on a Sales Order via email, which would simplify their signature gathering process.

Solution

Salespeople now have the ability to send signature requests via email from the Point of Sale. Click the Request Signature button and fill out your customer’s information to get started.

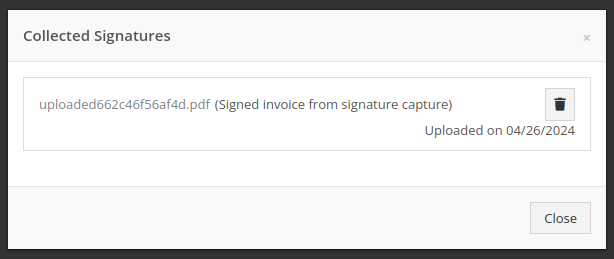

You can view previously signed versions of an Invoice by clicking “View Collected Signatures” in the Details section.

Signatures collected manually and via a card machine will now also save a signed copy of the invoice that can be viewed here.

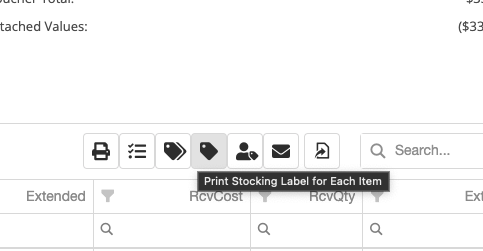

Opportunity: Receiving Clerks and Parts Managers have requested the ability to limit the amount of labels that were being generated on Receiving Voucher label printing. For parts departments who, for example, use bins instead of individually labeling each part, reducing the number of labels would save costs and paper waste.

Solution: We have added a button to the Receiving Voucher page called "Print Stocking Label for Each Item". This will generate one label per item, regardless of its received quantity. Additionally, you now have the option to exclude Special Order item labels from being printed.

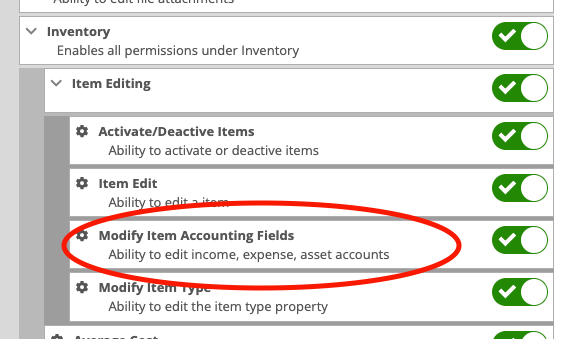

Opportunity: Managers have requested the need to restrict editing of accounting fields when editing or creating items.

Solution: We have updated the Item Dashboard to lock editing based on a new permission. Admins can find this new permission in Access Controls -> Inventory -> Item Editing. This will toggle editing on Item Income, Expense, and Asset Account fields.

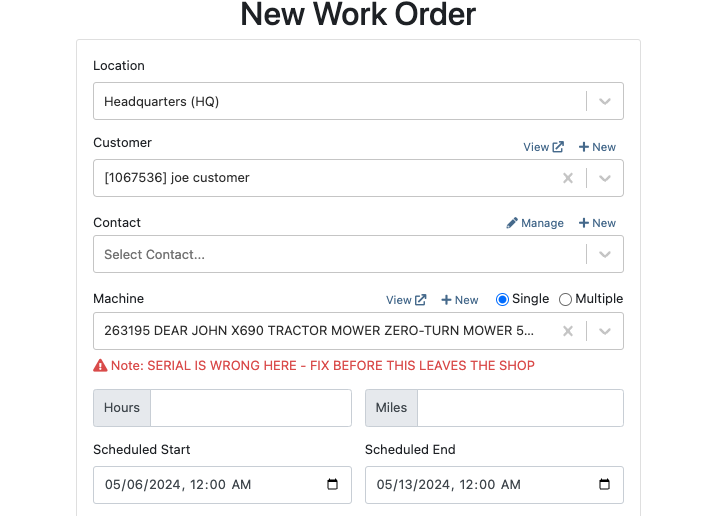

Opportunity: Managers using the recently-released Machine Warning Note feature have requested that this note be visible on Work Order pages.

Solution: We have updated the Work Order Dashboard and Work Order creation to display this note when the machine is selected.

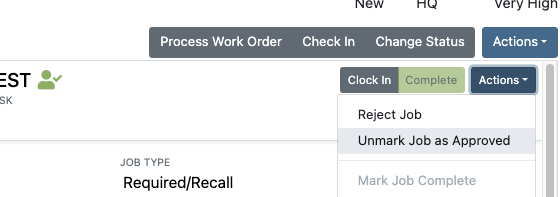

Opportunity: Service Managers have stated the need to undo a job Approval or Rejection. Previously, a user could only change an Approved job to Rejected, or vice versa.

Solution: We have added additional actions to Work Order Dashboard Jobs. If the job has been previously Approved or Rejected, the status can now be cleared.

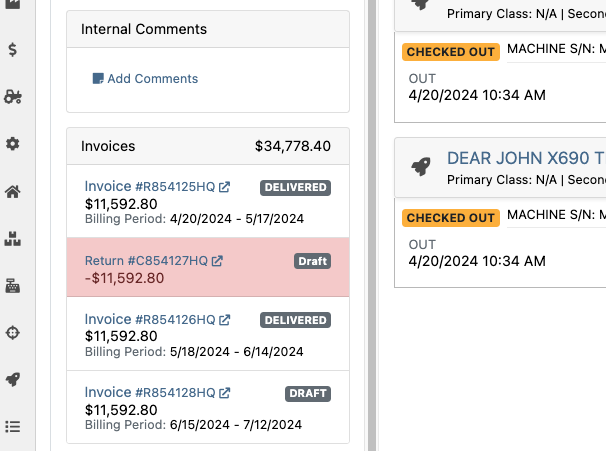

Opportunity: Rental Managers have requested the need to quickly view invoices that were returned against a previous Rental Contract invoice. This would help them reduce the possibility of the costly mistake of missing a billing period for a customer if a return was not immediately visible.

Solution: We have updated Rental Dashboard to clearly display when a returned Invoice is recognized against a previously billed contract. The returned invoice will be shown underneath the original Sales Invoice.

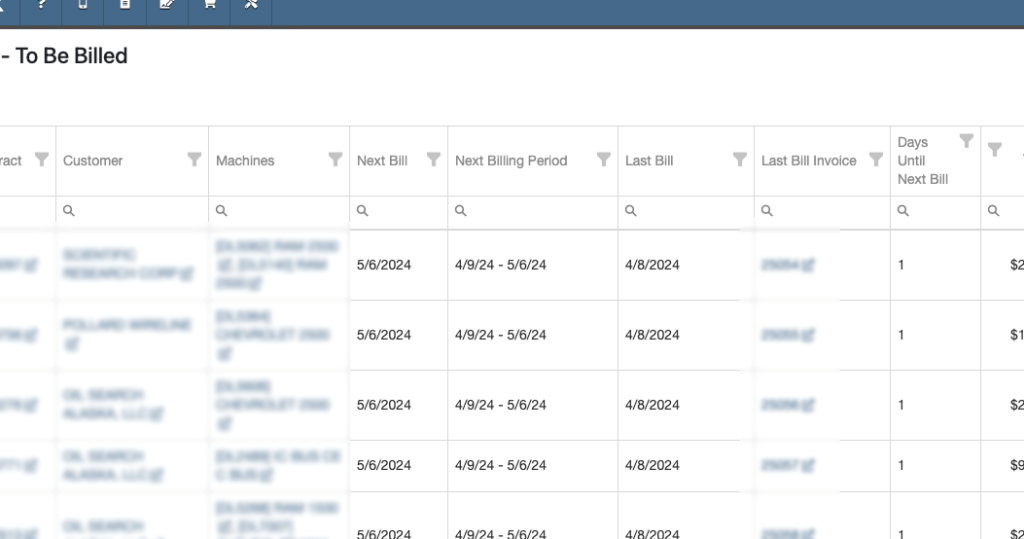

Opportunity: Rental Managers have requested to have more specific billing information at-a-glance when reviewing Rental Contracts to be billed. We previously only showed Next Bill and Last Bill dates.

Solution: We have added two new columns: Next Billing Period and Last Bill Invoice. Next Billing Period will show the billing period of the next upcoming billing cycle for each Rental Contract. The Last Bill Invoice column is a link to the most recently generated Invoice for each Rental Contract.

Complaint: Purchasing Managers mentioned that when using MPO Vouchers and reviewing machines to allocate to Sales Orders, sometimes a line would show as having available Sales Orders to associate when there were actually none available.

Cause/Correction: Fixed. Additionally, all MPO Voucher users should now have been moved over to the latest version of Machine Allocation.

Complaint: Technicians using the Work Order Parts Request feature noted that the Parts Searcher was not pulling in all available parts, and displaying incorrect item identifiers.

Cause/Correction: We have made several updates to this feature: the Parts Searcher should now be searching the complete parts catalog, and the parts displayed should now be showing its proper item numbers. We have also made improvements to the layout.

Complaint: Rental users in multi-location dealerships mentioned that when searching for machines to rent, they would notice some "Available Machines" incorrectly marked as “Conflict” status.

Cause/Correction: We have updated the Rental Searcher to correctly display availability for multi-location dealerships.

Complaint: Accountants using QuickBooks Online stated that loading Payments into Flyntlok was taking a lot more time than usual, and would sometimes fail after an extended period of time.

Cause/Correction: We identified that this was caused by attempting to load in a large number of payments. We have made significant improvements to this functionality to handle larger loads.

Complaint: Rental users who bill by the hour noticed that the start and end times they would enter into the New Rental page would sometimes carry over the wrong date and duration to the Rental Contract.

Cause/Correction: Fixed.

Complaint: Rental Managers mentioned that when invoicing a rental for a machine configured with attachments, its attachments were not showing on the invoice.

Cause/Correction: Fixed.

Complaint: Purchasing Managers noted that when a machine is received on a voucher, and the voucher is then canceled, some of the machine data from the canceled voucher remained on the machine.

Cause/Correction: We now clear the serial number, vendor PO associations, and date received of machines on a canceled voucher.

April 24th, 2024 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

The Point Of Sale (POS) allows a user-friendly way to create Sales Orders (SO), quotes, and other internal documents. It offers a large range of customizable features that expedite and improve customer experience. These features include texting customers when parts arrive, sending out customer experience surveys, emailing customer invoices, and more.

Users can access the POS from the Quick Searcher by searching for a Sale Order. You can also click the Sales Order number wherever found in Flyntlok.

The most common way a user can create a Sales Order is by clicking the Shopping Cart icon located in the Top Menu Bar.

The other ways users can create a Sales Order:

Once arrived, a dashboard appears which includes blue tabs labeled:

The blue Customer tab is the initial tab opened when creating a new Sales Order. This tab prompts users to fill in Customer, Contact, Machine, and other general information. Head to the Customer article for further information.

The Shipping tab includes the ability to create, edit, and view customer Shipping Addresses, and designate inbound and outbound Shipping Methods. Head to the Shipping tab article for further information.

The Details tab includes Customer Purchase Order, public and private message fields, and other actions and settings. Head to the Details article for further information.

The Payment tab give you options to take Payment, Quote, Copy and more. Head to the Payment or Actions article for further information.

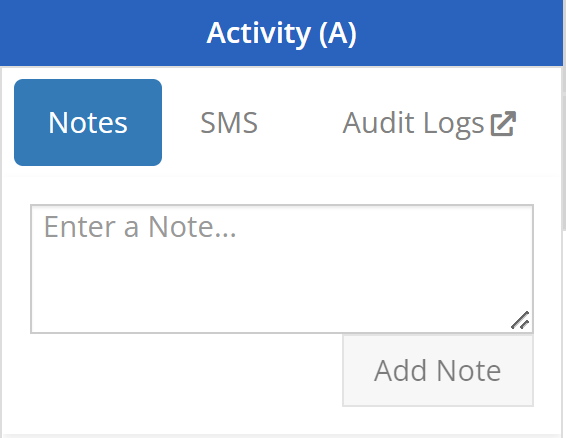

The Activity tab includes a Note Section, SMS options, and a link to the Sales Order Audit Logs. Head to the Activity article for further information

Clicking below the prompted Customer tab into the center of the POS or clicking above the Shipping, Detail, or Payment tabs, will reveal the Item Search Bar, Item Line Details, and other Sales Order Features. Go to the Item Search Bar article for further information on the following Look-up functions.

For further information on looking-up and entering Items in the Point of Sale, go to the Item Search Bar article.

![]()

In the homepage of your POS, users can access all necessary Sales Order Actions. Many of these features are displayed by relatable icons in the top right corner of the POS and include:

For further information on Point-of-Sale Actions, go to the Actions Articles.

By searching or scanning, items are added to the Sales Order. In each item line, users can:

Above the Shipping tab, users may view the status, the Sales Order number, view Downstream Operations, as well as choose to Delete or Order. Also, above the Activity tab, badges describe additional context of the Sale Order and Customer. For further information on Line Items, go to the Line Items article.

For further information on POS Hotkeys, go to the Hotkeys article.

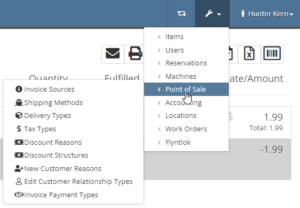

Settings for the Point of Sale can be found underneath Editors (Wrench) -> Point of Sale. These settings allow users to adjust:

For further information on Point-of-Sale Administration, go to the Point-of-Sale Administration article.

Check out the newest updates to the Flyntlok Equipment Dealer Management System.

We are now integrated with Volvo Extended Offer. When you order extended offer parts from Parts Linq, Flyntlok will receive order confirmations and shipping confirmations for these orders' styles.

Volvo plans to let you place these orders from your business system in Q3/4 of 2021. We will add that functionality when it is available.

When clocking into a DMS work order, you can now choose a job to clock into right away!

You will also see the option to clock in listed on the jobs as well.

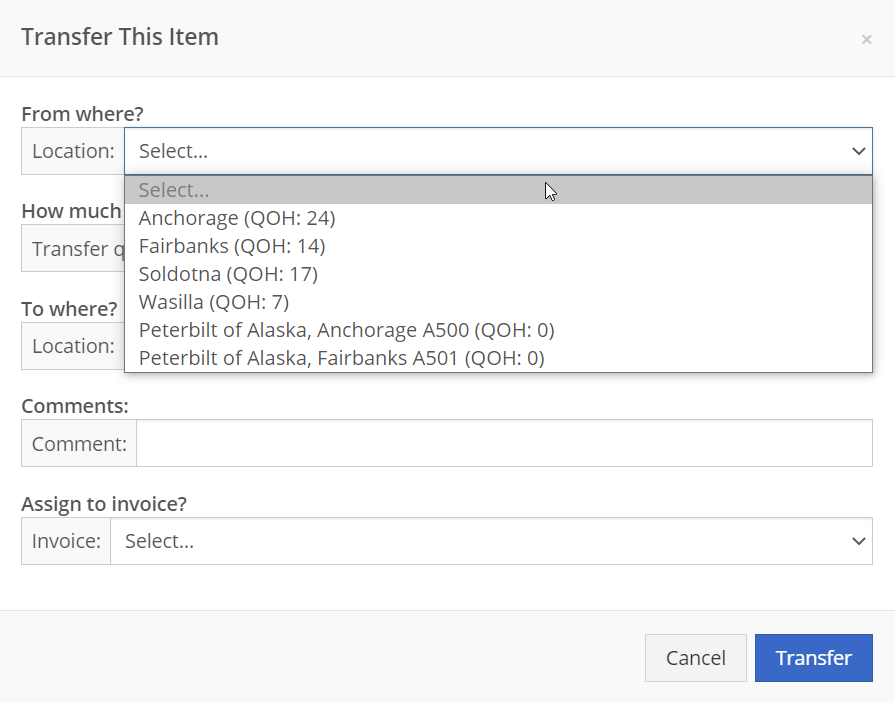

We made some small adjustments to the form for requesting parts transfers. The first field in the form is now the "From where?" section.

We also now show you the QOH at the location in the dropdown.

You can now give a customer multiple discounts. To do this, navigate to the customer editor. In the "Accounting" section, you can set the discounts.

These discounts must be pre-defined by an administrator at your business.

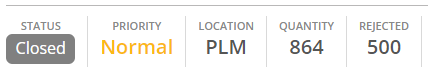

We will now show you the amount that has been rejected in the top banner of the work order.

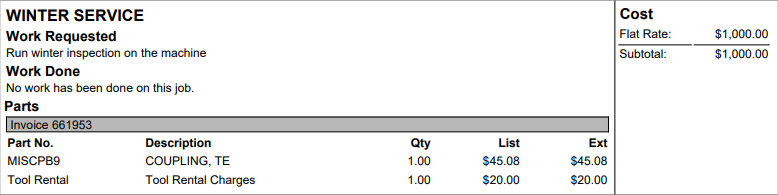

We have adjusted the DMS work order PDFs to now account for flat rate job pricing.

We have added a new task that will get created for one user, set at the company level when a new vendor is added. This will allow for the vendor's accounting configuration to be double-checked and prevent any incorrect postings.

We have added logging to the Flyntlok Journal Entry system.

Now, when receiving an item, you will be able to edit or set the bin location.

The clock icon on the list of open DMS work orders will now be highlighted if any tech is clocked into the work order. Previously, it was only if the technician assigned was clocked in.

If a job template does not have a default labor type, we will default for you.

We found a bug that prevented draft parts orders from being created when adding a job template to a work order. That is fixed, and adding a template to a work order that contains parts will create a draft order of those parts.

We've tracked down and resolved an issue with cores being added to purchase orders with incorrect purchasing locations. Occasionally, when an item was being purchased with a core, the core added to the purchase order was for the incorrect store location.

We found a bug in notification settings where we were overriding your setting. That is fixed, and they should stick now!

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!