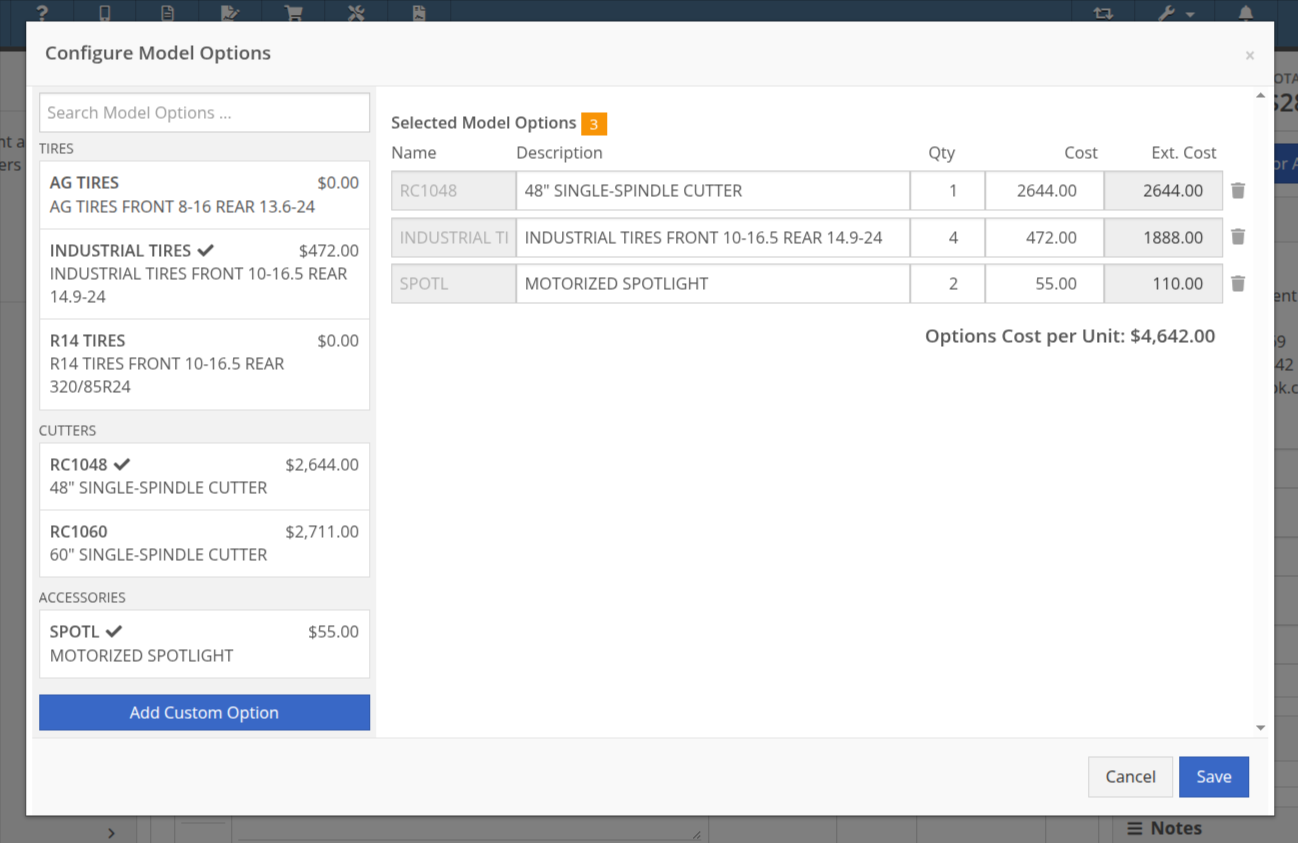

Models can now be configured to be quoted, sold, and purchased with quantities of Model Options. You will find that quantity amounts can now be set throughout the entire quoting and purchasing workflow. This includes:

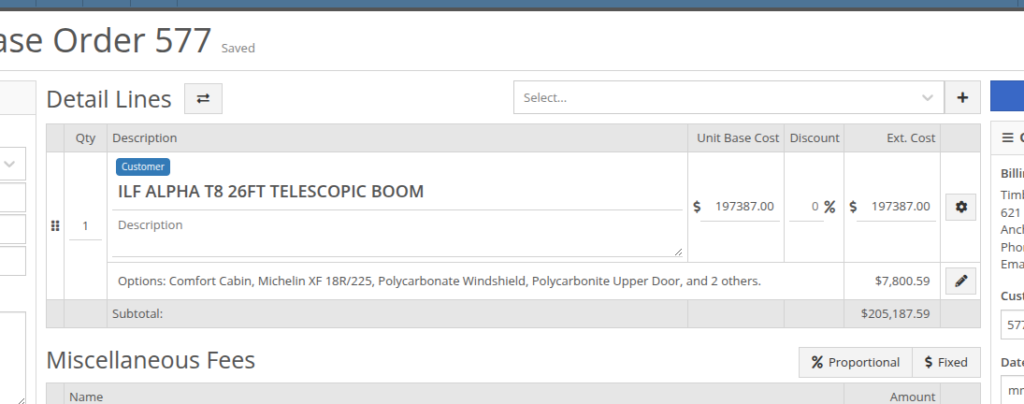

Purchasers wanted the ability to edit the cost of Model Options while editing a Machine Purchase Order. Previously, when ordering Models and then finding out about price changes after submitting the PO, the only way to adjust the cost was to either recreate the Purchase Plan, or remove all the existing options and recreate a new set of Custom Options with the updated pricing.

We have updated Model Options editing capabilities on our Machine Purchase Order page. You can now edit descriptions and costs. Similar to how Model Options was updated across the rest of Flyntlok in a previous update, this should feel more inline with all other purchasing workflows. And yes, quantity can be edited here too:

Opportunity

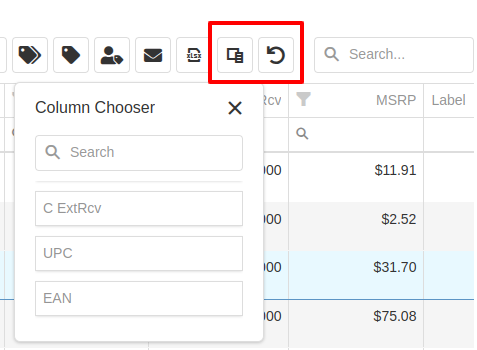

Purchasing teams wanted the ability to view the Item’s MSRP directly within the Part Purchase Order interface.

Solution

Item MSRP is now available in the column chooser on Part Purchase Orders, allowing users to include it in their custom layout. Further, some datagrid improvements enable layout saving and resetting for a personalized experience.

Opportunity

Service Managers needed a way to troubleshoot large machine Receiving Vouchers more easily. Without an export option, reviewing long lists of received machines was time-consuming.

Solution

Machine Receiving Vouchers now include an "Export CSV" option in the Actions dropdown, allowing easy export of all voucher lines for review in Excel.

Opportunity

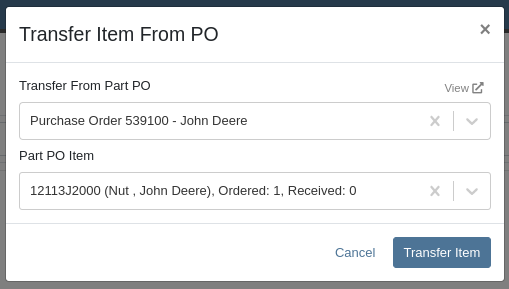

When vendors shipped parts on a different Purchase Orders than originally ordered, parts staff had to manually edit the original Purchase Orders and recreate the receiving voucher to ensure accurate receiving.

Solution

Added the ability to transfer items between Purchase Orders. When an item is transferred, it is automatically included on the open Receiving Vouchers of the Purchase Order. This functionality is available from the Actions dropdown on the Purchase Order, labeled "Transfer Item From PO."

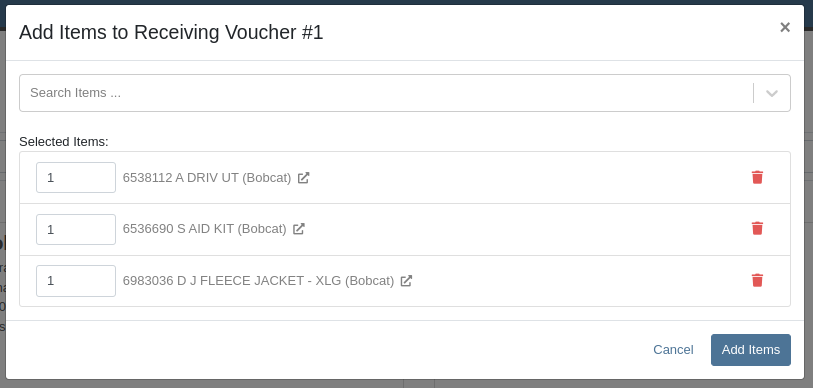

Opportunity

Parts Managers reported inefficiencies (and boldly challenged Flyntlok to solve this problem) when vendors shipped additional parts that were not originally listed on a Purchase Order. To receive these unexpected items, users first had to update the PO manually before they could add them to the voucher.

Solution

Challenge Accepted, Neil! Introduced a new “Add Items” option under the Actions dropdown on the Receiving Voucher page. This allows users to add missing parts directly to the voucher. When items are added this way, the corresponding Part Purchase Order is automatically updated.

Opportunity

Parts Managers requested visibility into both the Item MSRP and List Price directly on the Part Purchase Order PDF to assist with pricing validation.

Solution

Added a new setting: "Display Item List Price and MSRP on Parts Purchase Order PDF." When enabled, this setting will include both the MSRP and List Price of each item on the printed Purchase Order PDF. To turn this feature on, go to Flyntlok Settings and find it under the Purchasing section.

Opportunity

CRM users needed a more flexible and powerful search when working with leads. Previously, searching by phone number or email returned no results, limiting the usefulness of the search function.

Solution

We’ve enhanced the global search on the "All Leads" report to include phone numbers and email addresses, making it easier to find leads with limited information.

Opportunity

CRM users reported issues with lead handling, noting that new Leads that were created from the “Text Us” widget or from Zapier weren’t automatically linking to customers and that users could initiate Sales Orders, Work Orders, and Rental Contracts without a customer assigned.

Solution

A Customer will now be automatically assigned to a new Lead if the phone number or email matches a contact on exactly one customer. Additionally, a customer must be assigned before creating a Sales Order, Work Order, or Rental Quote from a lead.

Opportunity

Sales Managers needed a way to display selected “Machine Options” on the Sales Order and invoice PDFs.

Solution

We’ve updated the Sales Order system to include ”Machine Options” when a machine is sold using the “Sell Machine” button or through the Machine Dashboard. Options now appear directly on the Sales Order page and in the PDF.

Opportunity

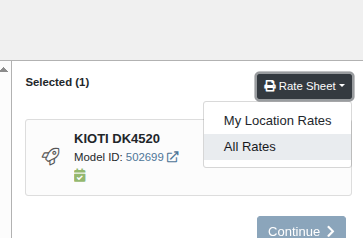

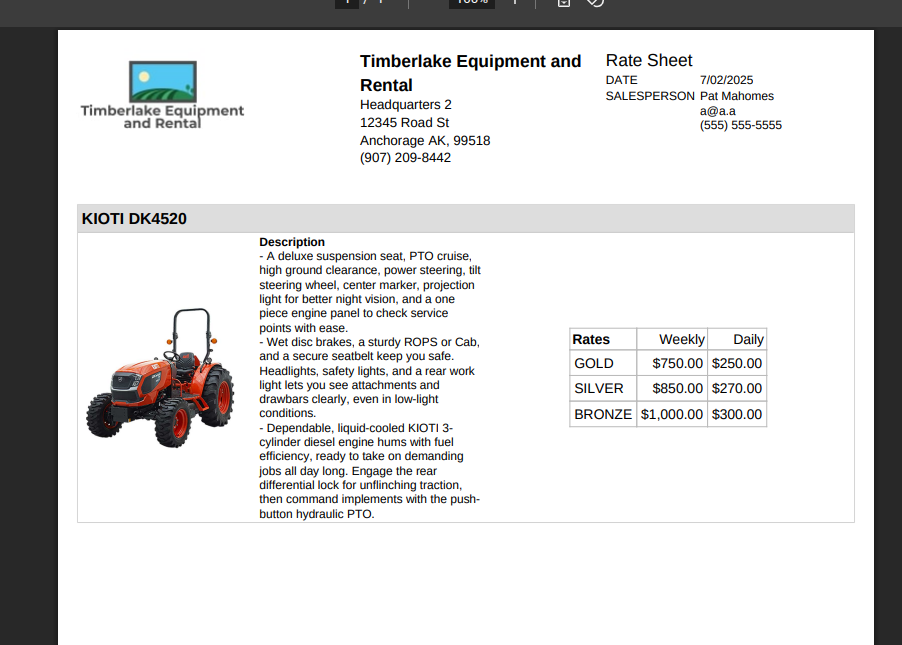

Salespeople requested the ability to show multiple Rent Schedules when printing a rate sheet for their customers. This is because many Rental Departments use tiered pricing to support upsell opportunities, such as offering discounts for preferred customers or better rates for long-term rentals. Being able to present flexible pricing options would help to maximize rental opportunities.

Previously, rate sheets were limited to showing only the default Rent Schedule based on the contract’s location.

Solution

The updated Rate Sheet now offers two display modes:

Opportunity

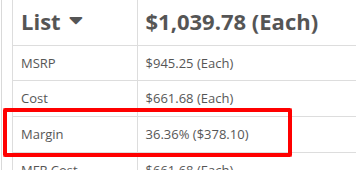

Users reviewing item costs wanted a quicker way to assess profitability without needing to do manual calculations. Visibility into margin and profit directly on the Item Dashboard supports faster pricing and purchasing decisions.

On Item Dashboard, when clicking to reveal costing information, we now show margin percentage and profit amount.

Complaint: Sometimes inactive items are being displayed in the alternates view when viewing part through the search.

Correction: Fixed.

Complaint: Machine Purchasers reported that they would sometimes receive a number of duplicate notifications when they complete a Machine Purchase Order derived from Machine Purchase Requests.

Correction: Only one notification will be received.

Complaint: Users reported that machines that were currently rented out were showing a blank space in the Status column when searched using M?.

Correction: Fixed.

Complaint: Sometimes the Part Sales History report was becoming unresponsive when loading.

Correction: Fixed.

Complaint: The "Work Order Invoice Terms" setting in Flyntlok Settings was not functioning as expected. Instead of displaying its contents on the final invoice, the system was incorrectly using the general "Work Order Terms" setting.

Correction: The "Work Order Invoice Terms" setting now correctly controls the terms displayed at the bottom of a Work Order’s final invoice.

Complaint: Technicians and Service Writers noted that multi-day scheduled events created through Service Scheduler were not appearing in the assigned technician's "My Work" view.

Correction: Fixed. Multi-day scheduled events now appear on an assignee's view when filtering by any date that falls within the start and end date of the event.

Complaint: Service Writers reported that the “Billable Hours” as reported and shown within the Work Order Dashboard did not correctly carry over to the final Invoice.

Correction: Fixed.

Complaint: Inventory Managers reported that on Item Dashboard, they were unintentionally able to transfer more quantity than was available at the source location.

Correction: Fixed. Improved UI to show and prevent when a requested transfer amount exceeds quantity on hand at the selected location.

Complaint: Salespeople noted that sometimes Sales Orders generated by a Sparks customer showed up in their dashboards without an ID set, resulting in the Sales Order link not being clickable.

Correction: Fixed.

Complaint: Technicians reported that when attempting to attach photos to a Work Order from mobile using an Android-based device, they were only presented with the option to select existing photos. Users on iOS devices had the additional option to take a new photo.

Correction: Fixed.

Complaint: Users mentioned that they were not receiving a notification when their password was close to expiring.

Correction: Fixed.

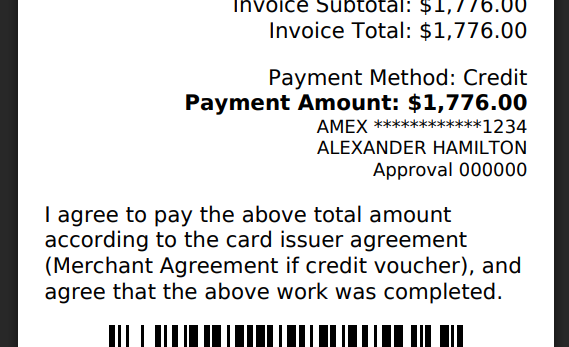

Complaint: Salespeople reported that when accepting a card payment on a Sales Order, the approval code was not appearing on the thermal receipt PDF.

Correction: Fixed approval numbers not showing. Additionally, we now include more card information:

Complaint: Users were able to undo the receiving of a Special Order item that was already fulfilled, leading to incorrect allocation states.

Correction: Flyntlok now warns users when attempting to undo the receiving of a Special Order item if the linked Sales Order is already in a Delivered status.

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Opportunity

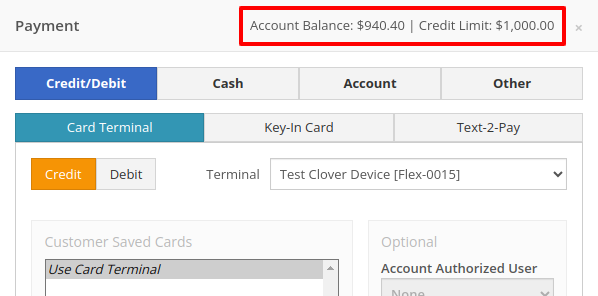

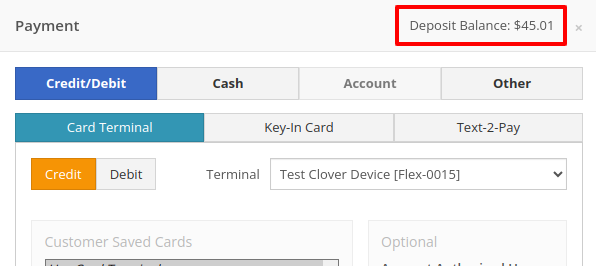

When making a sale, knowing the Customer’s account or deposit balance is helpful to the salesperson. To access this information, they would have to access the Customer’s dashboard page, which was inconvenient and time consuming with a customer waiting.

Solution

We’ve added the Customer’s balance information to the top of the Payment popup. When clicking the green “Pay” button on a Sales Order, will now see this information displayed at the top of the box:

For non-account customers, it will show their deposit balance instead:

Opportunity

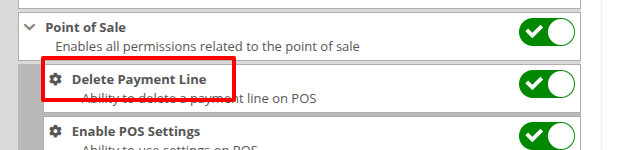

Managers requested the ability to allow or restrict deletion of payment lines on Point of Sale based on their user roles.

Solution

We have added a new permission on our Access Controls page. The "Delete Payment Line" permission can be found under the "Point of Sale" category. Disabling this permission will block deletion of payment lines for Sales Orders in any status.

Opportunity

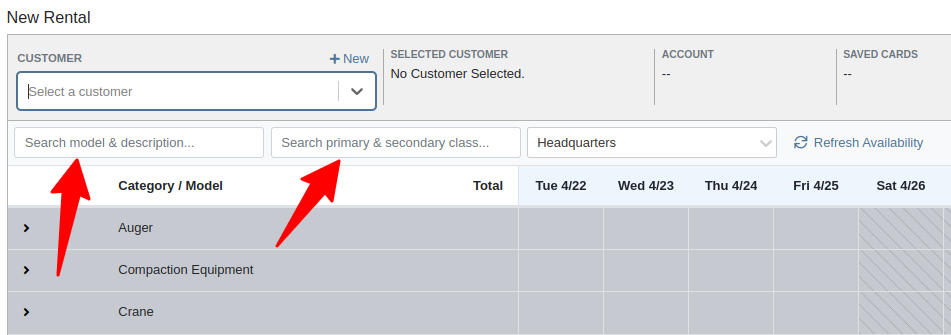

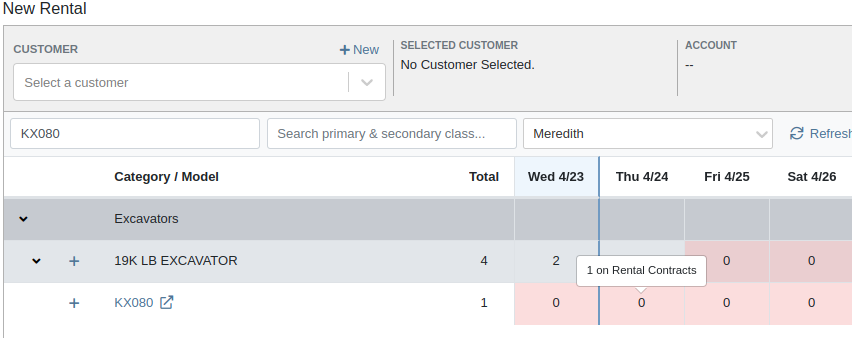

Previously, the text searcher on the Rental Category Timeline combined both Model and Class searching at once. Rental clerks complained that when they searched by a Machine’s Class specifically, it would display no Models underneath, because the searcher required that both Model and Class match the search filter.

We split the text searcher into two separate inputs, for Models and Classes:

Users can still use the Model searcher to limit results to Models whose Make, Model, or Description matches the filter. Additionally, the Class searcher can be used to limit results to Classes whose name matches the filter.

Having both options available allows users to precisely specify which results they are looking for.

Opportunity

Rental Managers noticed that when viewing a Machine Dashboard, the rental rates from a different location would show first by default, causing confusion. They wanted the system to prioritize the user's location-specific rental schedule instead.

Solution

We’ve updated the Rental Rates menu so that rental rates matching the user’s current location are shown at the top of the list. Additionally, we added location badges to clearly identify which rental schedule belongs to which location, making it easier to find the correct rates quickly.

Opportunity

Managers using Flyntlok's Shopify integration requested more insight into a Shopify-linked Item's status. Previously, we would only show if an Item was initially linked to Shopify. Modifications made to the Item in Shopify that resulted in a de-sync was not being communicated clearly on our Item Dashboard. This led to confusion about the actual sync status of the Item.

Solution

The "In Shopify" checkmark at the top of Item Dashboard has been replaced with a dedicated Shopify section in Item Dashboard. This allows you to view more details, including connection status of the Product, sync status, and the last sync time:

An Item with no Shopify link will display as "Unlinked":

In the case of a linked item that can no longer be found in your Shopify store, the Item's connection status is displayed as "Previously Linked":

Additionally, there are two buttons to external pages provided: "View in Shopify Store" directs you to your storefront's Product page. "Edit in Shopify" directs you to the Product on your Shopify Admin page.

Opportunity

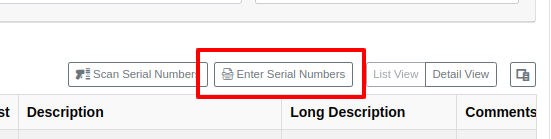

Dealers receiving large quantities of Models requested a more streamlined way to enter Machine serial numbers in bulk. While Flyntlok previously supported bulk entry via barcode scanning, we did not have support for bulk text entry. This is especially important for dealers who prefer to enter serial numbers from a vendor's invoice before physically receiving the stock.

Solution

To use this feature, click the "Enter Serial Numbers" button near the top of an MPO Voucher:

From this dialog, select a Model, then type or paste in the serial numbers. Serial numbers can be separated by line breaks, commas, or a mix of both:

Check "Detect duplicates" to remove any duplicates before proceeding to the next step.

Clicking on "Next" will reveal the preview. From here you can verify that the serial numbers to be applied look correct. We will also display warnings if too many serial numbers were entered as compared to the number of machines on the voucher. If too many are entered, you can remove lines as needed, or click on "Back" to restart the process.

Use the "Overwite existing serial numbers" checkbox if you wish to ignore any existing serial numbers entered on that model. This is especially useful for dealers who use a placeholder serial number.

Complaint: Parts Managers asked for the ability to edit comments on Part Transfers that have been received.

Correction: Comments can now be edited.

Complaint: Service Managers noted that they were sometimes not able to add a new “Work Action” through the Work Actions Admin Editor.

Correction: Fixed.

Complaint: Rental Managers mentioned that when attempting to edit the default title or body for a contract in Rental Settings, the changes were not appearing on newly created Rental Contracts.

Correction: Fixed.

Complaint: Inventory Managers noted that when printing a Receiving Voucher PDF, the footer did not contain the "Generated by" user and timestamp info that commonly appeared on other PDFs.

Correction: Fixed.

Complaint: Inventory Managers complained that when adding a Model Option, sometimes the currency would not be correctly set.

Correction: Fixed. It will now default to the Vendor's currency when adding a new Model Option.

Complaint: Managers reported that under the Balance Sheet section on the mobile version of the Machine Dashboard, the Liabilities section was not accurate and would always appear as $0.00.

Correction: Fixed.

Complaint: Rental Clerks reported that sometimes the “Category Timeline” view on the New Rental page would report no conflicts, even when the Model had Machines that were out on rent.

Correction: Fixed.

Complaint: Rental Clerks noticed that some machines showed days with conflicts (denoted by colored cells), but when they clicked on the cell the pop up would show “No Conflicts”.

Correction: Fixed.

Complaint: When printing a Purchase Order, core items were appearing twice on the PDF.

Correction: Fixed.

Complaint: Damage waivers were not being automatically applied to new customers without insurance.

Correction: Fixed.

Complaint: Customers using Sparks were unable to select the "Account" payment method and were forced to use a credit card to place orders.

Correction: Fixed. We've restored the "Account" payment option for eligible customers in Sparks.

Complaint: Parts Managers noticed that John Deere information was failing to load with Flyntlok’s API link to John Deere for some parts.

Correction: Fixed. The lookup now ignores white spaces at the start or end of part numbers.

Complaint: Managers reported times were showing in the incorrect timezone on the Issue Dashboard.

Correction: Fixed. Times shown on the Issue Dashboard will be displayed in the current location’s timezone.

Complaint: Technicians reported that some parts they search for on the desktop Work Order don’t appear in the search results when requesting parts on Mobile Work Orders.

Correction: Fixed.

Complaint: Parts Managers complained that they were not able to cancel a Reversal on Part Receiving Vouchers.

Correction: Fixed.

Complaint: Rental Clerks with AvaTax integration noted that they were sometimes unable to reverse Invoices.

Correction: Fixed. This issue only affected reversing of Rental Return invoices whose original sale was processed by AvaTax.

Complaint: Inventory managers using MPO Voucher's detail view complained that they were seeing a "De-sync on Machine Cost" warning even though no changes were being made to the cost.

Correction: Fixed. This was causing bugs in other editable fields on the same view, sometimes preventing the user from editing those fields.

Complaint: Managers mentioned that they were not able to add a note to an issue ticket immediately after submitting it.

Correction: Fixed a bug where the note input was not appearing on issues in "New" status.

Complaint: Service Writers noted that their customer SMS messages were displayed in the wrong order on the Activity Tab of Work Order Dashboard, displaying from oldest to newest.

Correction: Adjusted SMS message history on Work Order Dashboard to always display the newest messages first.

Complaint: Sales Managers mentioned that they were sometimes unable to print a Packing Slip, and that it would show up as a blank PDF.

Correction: Fixed a bug where special characters in a Customer’s contact record would sometimes cause an error in displaying Packing Slip PDFs.

Complaint: Managers noted that their notifications for an expiring Machine Reservation was not showing the correct Machine ID.

Correction: Fixed.

Congratulations are due to Flyntlok staffers Michael F. who welcomed his first baby on April 25, a bouncing boy named Bogdan! And Dylan T. welcomed baby girl Willow (number 3) on May 6! These future Flyntlokers will be coding new features and closing out tickets in no time!!

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

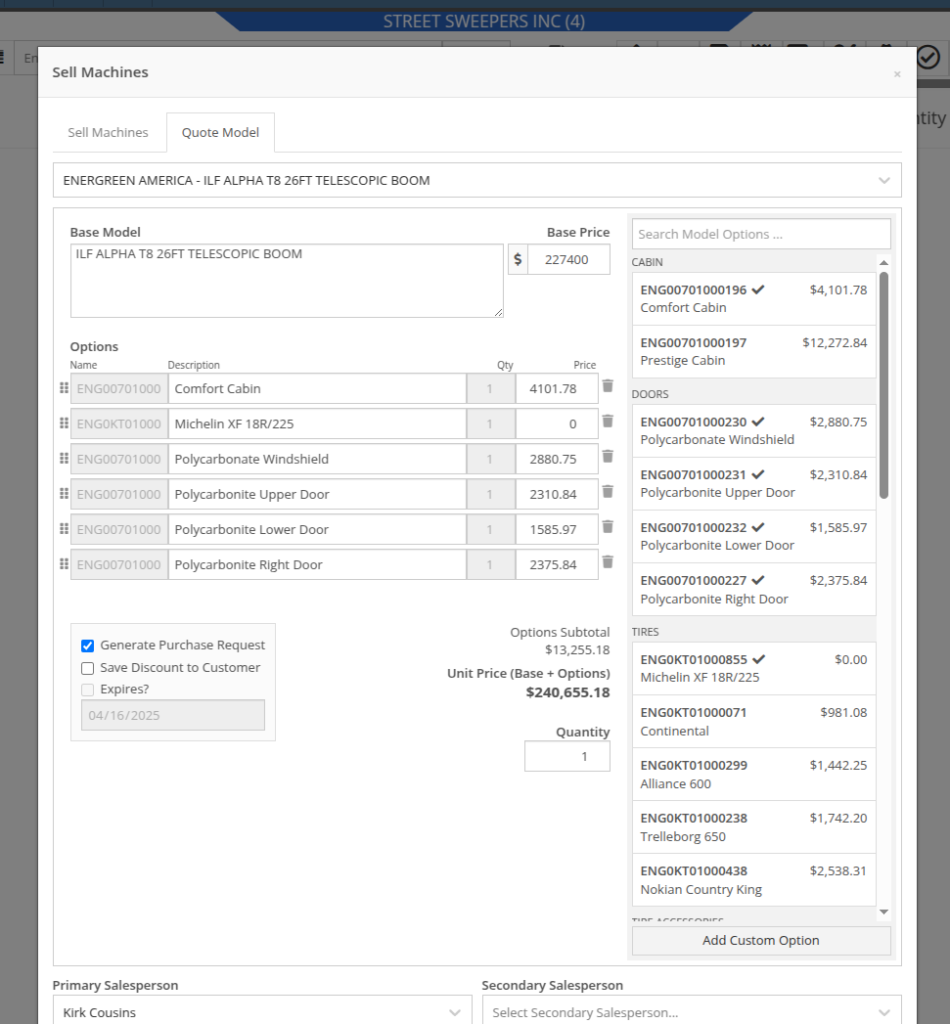

Selling complex, highly configurable equipment should be smooth, accurate, and hassle-free. That’s why we’ve enhanced Model Options and Purchasing workflows to give you more clarity, flexibility, and control.

Say goodbye to clunky menus! We’ve rebuilt the Model Options experience to make quoting faster and more intuitive.

Above: Cool search bar

As-Configured Price Breakdown

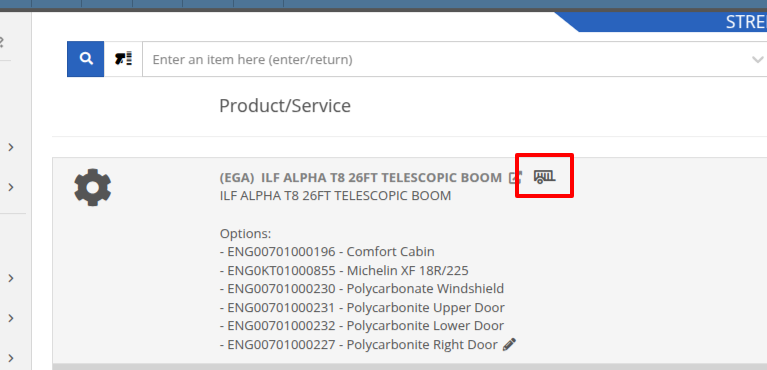

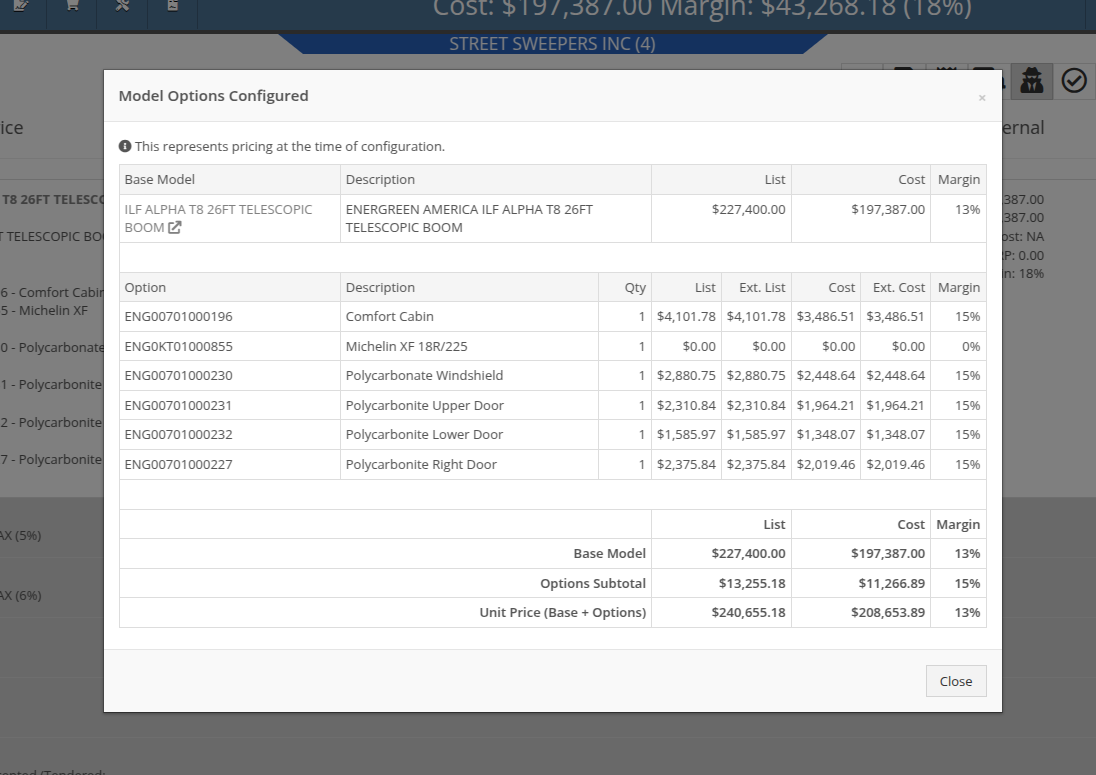

In Flyntlok, when quoting a Model, the configured price is applied to the Sales Order line, and the Options are listed in the Description note. Unfortunately, that meant that detailed pricing about the model's exact configuration were lost. With this new update, we will now save the details as configured. This will allow you to review the line-by-line breakdown of the Model's exact configuration!

To view this, click on the trailer icon (it's not a comb like some people thought) near the configured Model's description:

On that same screen, users with permission to view cost details will see additional cost and margin information for deeper insights:

Note: Pricing is locked at configuration, meaning discounts or any price adjustments applied later will not affect the original breakdown.

Configuration Details on Purchase Requests List: Previously, Flyntlok only displayed the default cost of the Model, even if it came from a Quote with a configured Model. When generating a Machine Purchase Order from this page, only the base Model was added, and the Purchaser would then have to manually re-configure the Model to match the Quote. This could lead to potential inaccuracies in configuration or miscommunications between Sales and Purchasing departments.

To clear up communication at this step, more information is now available to view on the MPO page. Additional columns have been added to this view, which can be added via the Column Chooser:

More importantly, Machine Purchase Orders generated from a configured Model on a Sales Order will now retain the exact configuration all the way through. No more manual re-entry!

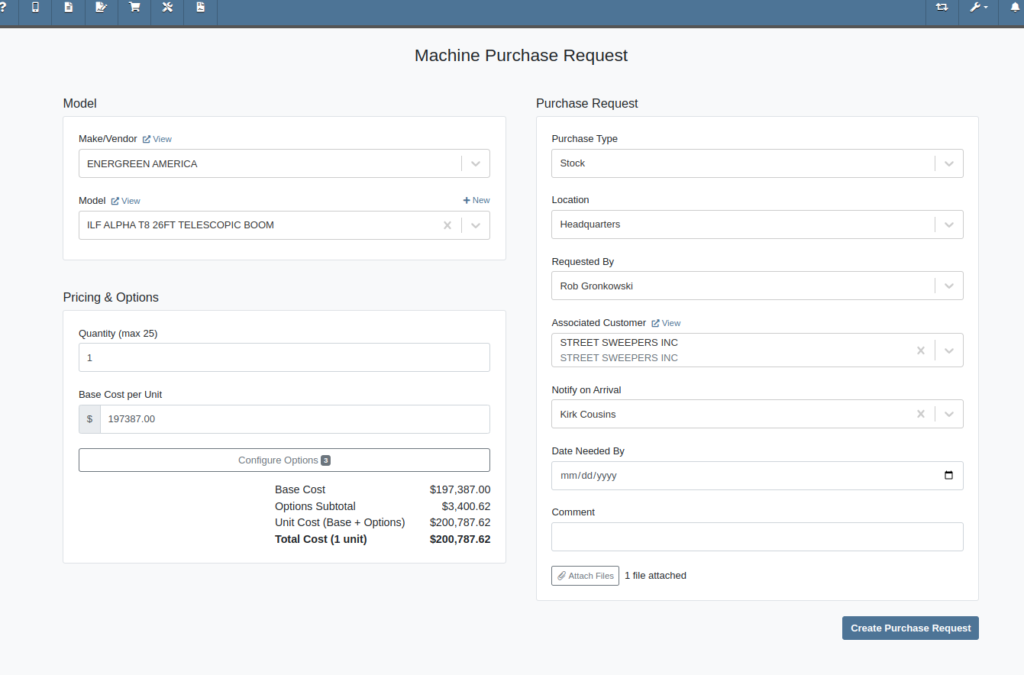

We gave the New Purchase Request page (Model Info -> New Purchase Request button) a fresh look to support fully customizable Model Options. In addition to Model Options, improvements have been made to show a more detailed cost breakdown, more fields when creating a new Model, and added support for multiple file attachments.

As with the Model Configuration tool on Point of Sale, Model Options here can be edited and rearranged as needed:

Multi-Currency Support? Of course!

Phew! We know that’s a lot, so if you have any questions, please reach out to your friendly Flyntlok Consultant with any questions.

Opportunity

Inventory managers requested the ability to customize the layout of their Receiving Voucher columns.

Solution

Receiving Voucher now supports fully customizable columns! This includes rearranging columns via drag-and-drop, adding and removing columns, and resizing columns.

You can access the "Column Chooser" by clicking on the icon as shown here:

Your column layout will be saved automatically. Clicking on the icon will reset the columns back to the default layout.

Additionally, an "MSRP" column is now available to be added to your layout.

Opportunity

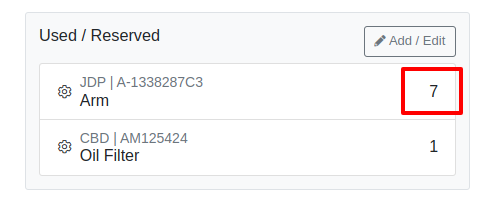

Service Technicians reported that adding a “Used / Reserved” Part on a Mobile Work Order Job would not respect the location at which the Part was used. The resulting invoice would then not correctly update the quantity-on-hand at the location of the Work Order.

Solution

Updated the Used / Reserved editor to break out Parts used by location in edit mode. This allows technicians to specify which location the Part was used at and maintain the correct Quantity on Hand.

When viewing a Work Order Job on mobile, the Used / Reserved section will look the same as before, which displays the total quantities of a part used across all locations. Once the user clicks "Add / Edit" on the “Parts Used” section, it will break the parts out by location. This allows the user to specify the location at which a part was used, and the resulting invoice will correctly adjust inventory quantity for that location.

For example, in the above image there are 7 "A-1338287C3" arms and 1 oil filter used on this Work Order in total. However, as seen below, once you enter edit mode it shows that 5 of the arms were used at Headquarters, while 2 arms were used at Kansas Branch.

When the user hits the "Add Item" button at the bottom, it will add the Item under whatever location is selected using the location dropdown. This defaults to the technician's assigned location.

Opportunity

Service Managers wanted the Service Scheduler to always open in the preferred calendar view (e.g. “Day View”), eliminating the need to switch manually each time.

Solution

The Service Scheduler and Job Scheduler calendars now remember the last view you used and will open to that same view the next time you return.

Opportunity

Rental Managers requested a way to ensure that either machine hours or miles are recorded before closing a Work Order. Relying on warning messages alone has proven ineffective, as users sometimes bypass them (argh, users…) .

Solution

We've added a new setting: “Require Machine Hours or Miles on Check-In”. When enabled, this setting will require users to input at least one of these values during the check-in process for a Work Order. To turn this feature on, go to Flyntlok Settings and find it under the Service section.

Opportunity

Users creating machine-linked invoices—such as cost-of-sale invoices—reported that changing the customer on these invoices would clear the machine selection. This disrupted workflows and required users to manually re-select the machine.

Solution

The invoice will now retain the selected machine when the customer is changed, as long as the new customer is an “Internal Customer”. This prevents unnecessary machine resets and maintains invoice-machine linkage for internal workflows.

Opportunity

Rental Managers wanted staff to easily view the “Minimum Cost Rate” of a rentable item during Rental creation. Clear visibility of this rate ensures staff can quickly and accurately communicate minimum charges to customers at the time of booking.

Solution

We've added the “Minimum Cost” field to key areas in the rental workflow:

This ensures that staff can quickly reference the minimum charge during rental setup.

Opportunity

Managers wanted the ability to control who can create Items in the system.

Solution

We’ve added a new permission that governs Item creation. To prevent users from creating Items, disable the “Item Creation” permission through the Access Controls.

Complaint: In some cases SurveyMonkey requests were not being sent via SMS, even though SMS delivery was expected.

Correction: Fixed.

Complaint: When using the Zapier integration to create a Lead, links added to the internal note field using <a> tags would have their href values replaced with the lead’s URL instead of preserving the original link provided in the Zap configuration

Correction: Fixed

Complaint: Despite the “Hide Kit Items on Sales Order PDF” setting being enabled, kit components were still appearing on printed final Invoices from Work Orders.

Correction: Fixed

Complaint: Service Writers noted that after merging several Parts Orders, it would fail when attempting to convert it to a Quote.

Correction: Fixed an issue where long messages entered in the Details area of the Sales Order page would display an error when creating a Quote.

Complaint: Receiving clerks reported that they were no longer able to access the Receiving Voucher page after entering a Fee line.

Correction: Fixed an issue where saving an invalid amount into a Receiving Voucher Fee line would sometimes cause the page to not reload properly.

Complaint: Ivan just won the March Madness basketball pool. This is after he won the Fantasy Football contest a few months ago. Ivan has been in this country for 2 years and is embarrassing the rest of us. And no one is more angry than Pawel who keeps finishing 2nd and thinks he should be winning.

Correction: Arguably this is just "as-designed." Please feel free to file a ticket to give Pawel a hard time.

March 26th, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!

Non Alaskans be like: Wait, what?! That’s a thing? Yes, Monday March 31 is Seward’s Day in Alaska and it is an official Flyntlok holiday. However, we recognize that all you folks outside of the 49th state are all going to be working. So we will have a reduced staff that day to manage your questions and to provide help; just understand if we don’t respond quite as quickly as we normally do...

And if you are bored this weekend, you can go read up about William H. Seward and fill your head with fun facts to amaze your lower 49 state or fellow Canadian friends. E.g. Did you know Seward was wounded in an assassination attempt at the exact same time that Booth killed Lincoln? It was part of a plan to slay the three senior members of the Executive Branch. (Spoiler: the assassination plan of Seward failed).

Here at Flyntlok we are not only building the most cutting-edge Dealer Management software, but we also want to act as industry thought leaders. To that end, we encourage you to follow us on LinkedIn and review our periodic blog posts. For example, here is a recent posting about our integration with Avalara for better sales tax management.

If you have a suggestion for a blog post that you think other Flyntlok customers, or the industry in general, might find interesting, please let us know. Drop us a line at sales@flyntlok.com.

Opportunity

Intuit is pushing applications integrated with QuickBooks Online, like good ol' Flyntlok, to upgrade to their newer back-end application interfaces. In order to continue communicating with them, we’re required to update Flyntlok’s QuickBooks accounting integration.

Solution

We took this as an opportunity to upgrade our entire back-end accounting integration services to improve reliability and eliminate some longstanding issues that have been impacting our users. We started to undertake this project at the end of 2024 and it will continue for several months still to come.

The first phase of this project was essentially invisible to you, but we have migrated all of our services to a newer technology and made it compatible with QuickBooks Online’s latest specs. Now, when an accountant hits one of the processing buttons on their QuickBooks Online page, it uses the updated logic. This back-end update is going to allow us to have better automated testing and allow us to make changes much faster. So, while not visible to you as a user, it's going to pay huge dividends for us going forward. We felt like you oughta know.

Additionally, we’ve resolved some long-standing bugs with the process, including where Credit Memos and Refund Receipts sometimes posted even when their associated Journal Entry failed; and Customer Deposits using Gravity credit card fees subtracted the fee from every payment. Those bugs have now been addressed.

Over the coming months we will provide notifications across all accounting-sync processes for failed transactions. We aim to tell you why a transaction failed, what the offending transaction was, and how to fix it. We want you to have the ability to fix issues on your own rather than forcing you to create a support ticket to resolve simple problems. Power to the people! Stay tuned..

Opportunity

John Deere offers an optional, dealer-paid service called Retail Parts Management (RPM) that helps dealers manage their parts inventory. A key tool from RPM is called JDPrism, which is used to manage dealer stock levels. Using JDPrism, RPM can recommend stock orders, special orders, and transfers between dealer store locations based on stocking levels and sales history.

Our John Deere dealers have requested an integration with JDPrism so they can leverage this powerful tool to better manage their inventory and receive suggestions from John Deere.

Solution

We have implemented an integration with JDPrism that allows dealers to better manage their John Deere parts inventory. To drive this integration, your John Deere parts inventory data (e.g. quantity on hand, sales history, etc.) will be uploaded to JDPrism on a regular schedule set by John Deere. Then, you can approve Orders or Transfers within JDPrism that will be ingested into Flyntlok periodically throughout the day (every 15 minutes or so) to create Purchase Orders and Part Transfers.

If you are interested in the JDPrism integration, please reach out to your friendly Flyntlok consultant for assistance.

Opportunity

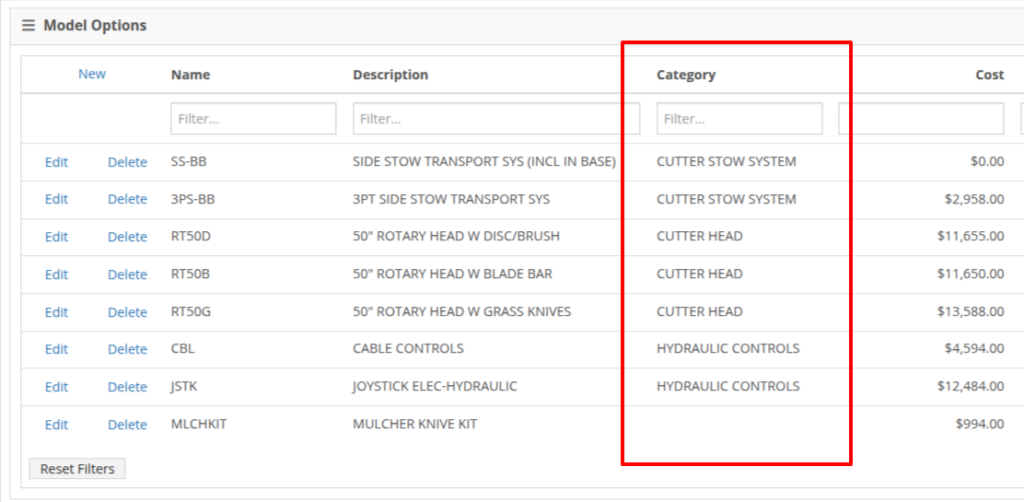

Sales Managers requested the ability to better organize their Model Options. Previously, managing Models with a large number of options could feel a bit overwhelming.

Solution

Our enhancements to Model Options are designed to make managing Model Options easier and more efficient. To simplify this, we’ve introduced two key improvements to the Model Options Editor:

NOTE: This is just the beginning of the “Model Option” fun! The new "Category" field will play a key role in upcoming enhancements to Model Options, including updates to Sales and Purchasing workflows. Stay tuned for more updates!

Opportunity

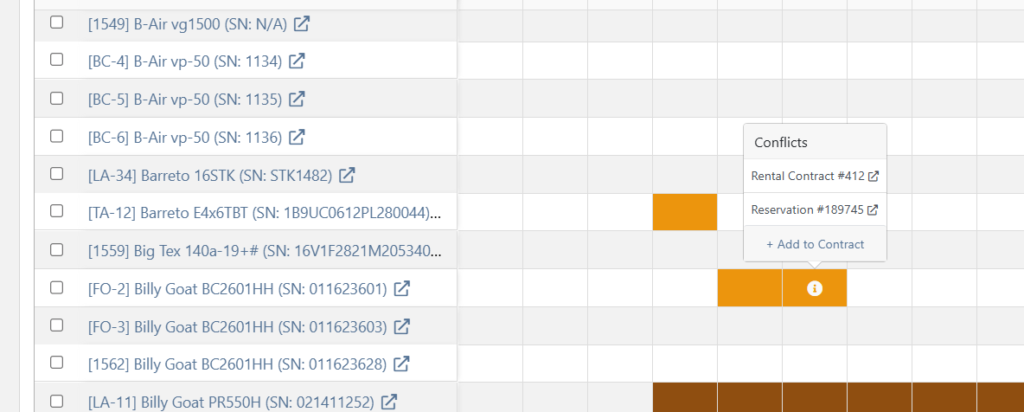

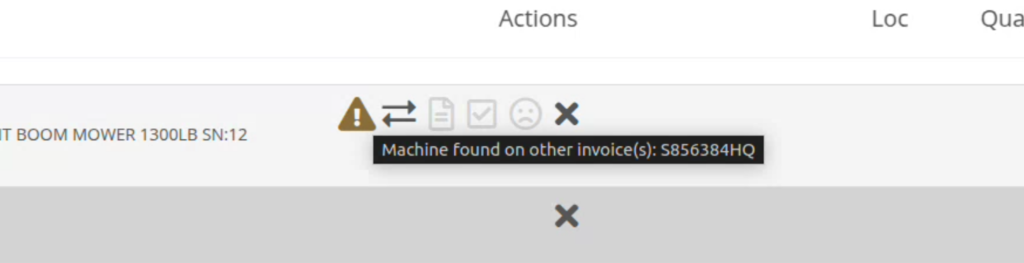

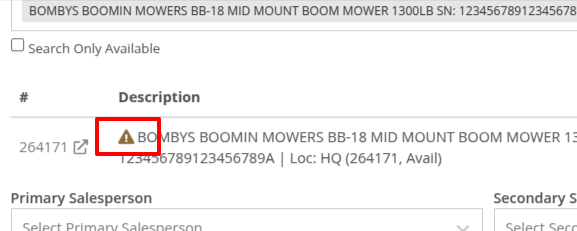

Salespeople shared that knowing about potential Machine sale conflicts earlier in the sales process would be a game-changer. While we already provided warnings during the sale processing stage, we did not show this critical information at any other time during the life of the sale. Selling the same Machine unknowingly could lead to accuracy issues and impact customer satisfaction.

Solution

An indicator icon will now appear on the Machine sale line whenever there’s a potential conflict, such as the same Machine being listed on another Sales Order. This gives you a heads-up before finalizing the sale.

We've also added the same indicator when searching for a Machine to add to a sale. This means you’ll know about potential conflicts before adding the Machine to the order, saving time and avoiding surprises.

Opportunity

Service Managers have asked for greater control over workflow automations, specifically at the Job level within Work Orders. Previously, our automation tools could only update Work Order statuses.

Solution

We've expanded this functionality to include Job-level status updates as well! By automating Job status changes based on key workflow actions, shops that rely on Job-level tracking can reduce manual updates, improve reporting accuracy, and ensure that technicians, parts teams, and service managers stay aligned in real-time. This means fewer bottlenecks, better communication, and faster turnaround times.

New Automation Triggers

You can now configure Work Order Jobs to automatically update their statuses based on the following actions:

Reach out to your friendly Flyntlok consultant for assistance in setting up these new automations!

Opportunity

Service Managers handling cost-of-sale (COS) Work Orders struggle to track the associated customers from the linked invoices, as these details are not visible on the Service Scheduler.

Solution

We have improved the display of the Work Order search results in the Service Scheduler to show the Cost-of-Sale Invoice's customer, making tracking and scheduling more seamless. Additionally, we have enhanced the title of scheduled events in the Service Scheduler when a Work Order is scheduled at the time of creation.

Opportunity

Users managing Cost-of-Sale Work Orders often need to verify the linked Sales Order and associated invoice. Previously, this required navigating back to the Sales Order, leading to inefficiencies and potential tracking issues.

Solution

Cost-of-Sale Work Orders now display the linked invoice directly within the Work Order, allowing users to quickly access relevant details without leaving the page.

Opportunity

Technicians faced challenges identifying machines because the mobile view did not display their descriptions.

Solution

Machine descriptions are now included in the Work Order Search display results on the mobile view, making it easier to identify equipment.

Service Managers have requested that Correction Notes be included on Work Order Estimates to provide more clarity and context when sharing with customers.

Solution

We've added a new setting: "Show Job Correction on Work Order Estimates". When enabled, this setting will include Correction Notes on newly generated estimates. To turn this feature on, go to Flyntlok Settings and find it under the Service section.

Opportunity

Users find adding or locating contacts on the New Work Order page to be cumbersome and occasionally buggy.

Solution

Opportunity

Sales Managers requested an automation that updates Shopify orders when an invoice moves to "Pickup" or "Delivered" statuses in Flyntlok. Previously, Salespeople had to manually update Shopify, which is time-consuming and redundant.

Solution

Flyntlok now automatically updates Shopify orders to reflect "Pickup" and "Delivered" statuses when corresponding invoice updates occur. This eliminates the need for manual intervention, streamlining order management.

Opportunity

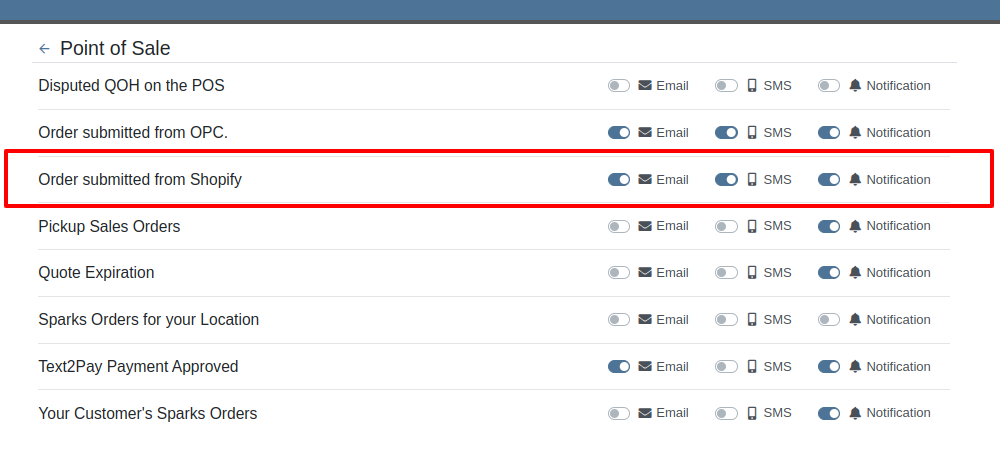

Sales Managers requested a notification for incoming Shopify orders, so that any salesperson that wants or needs to know about such orders will be notified immediately.

Solution

There is now a new notification for orders from Shopify that can be enabled for anyone who wants it.

Opportunity

Users found the reversal process for posted splits confusing, as they would end up in a "Delivered" status if the parent invoice was not also reversed.

Solution

Now, when attempting to reverse a split, a warning will inform users if the parent invoice must be reversed first.

Complaint: Parts Managers had noted that, when attempting to merge parts, sometimes mergeable parts would not show up in the list to be merged.

Correction: Fixed.

Complaint: When using Scan Mode on the Receiving Voucher, scanning a barcode resulted in a "Part Not Found" error, even though the part was listed on the voucher.

Correction: The issue was caused by a leading space in the scanned item number, preventing an exact match. The Scan Mode has been updated to automatically trim leading and trailing spaces from the scanned input.

Complaint: A technician was able to add parts to a Work Order after it had been invoiced, even though no changes should be allowed once the Work Order has been Invoiced.

Correction: Fixed.

Complaint: The total amount on the printed Work Order report was off by one cent compared to the final invoice.

Correction: Fixed the rounding of the estimated tax on the print, ensuring that the total calculation now matches the final invoice.

Complaint: Users were unable to edit the Certificate of Conformance (COC) requirement from the Purchase Order.

Correction: Enabled the COC field to be editable in PO edit mode, allowing users to update the requirement as needed.

Complaint: Sales Managers noted that they would sometimes receive duplicate CRM Leads generated from their marketing site's "Text Us" form.

Correction: Fixed an issue with CRM Text Us widgets where customers were able to inadvertently submit an inquiry multiple times.

Complaint: Managers complained that they were not able to update their Sales Order default footer in Flyntlok Settings.

Correction: Fixed. We have updated this setting to support longer default footer messages.

Complaint: Rental Clerks were unable to load Rental Dashboard without errors.

Correction: Fixed an issue where Rental Dashboard failed to load defaults when store hours were not configured in Rental Settings.

Complaint: Salespeople mentioned that some Sales Order links appeared broken on their CRM Lead Dashboard timeline.

Correction: Fixed. Deleted Sales Orders associated to a CRM Lead will no longer display as a link.

Complaint: Managers complained that when using the "Merge Model" tool, they were unable to find a model by searching its internal ID.

Correction: Fixed. “Merge Model” searcher can now search by internal Model ID.

Complaint: Sales Managers mentioned that when using the Bulk Update action on the Part Price Matrix page, it did not appear to be factoring in Unit Qty when auto-calculating list price. This happened similarly on individual updates via the new Pricing Matrix editor.

Correction: Fixed.

Complaint: Purchasers noted that when reporting an Exception on Part Purchase Orders, the PO status would not update.

Correction: Fixed. PO Status is now automatically refreshed when reporting an Exception on a PO or any of the PO's associated Vouchers.

Complaint: Fleet Managers noted that when printing a Machine “Internal Asset Report”, the Machine's ID appeared to be missing or incorrect.

Correction: Fixed report to show the proper Machine ID.

Complaint: Service Managers complained that when printing a Work Order Worksheet PDF, sometimes the Jobs would be listed out of order.

Correction: Fixed.

Complaint: Salespeople were unable to deliver Invoices because the "Credit Auth" payment type was applied to Multi-Pay Sale.

Correction: Disabled "Credit Auth" payment type in the Multi-Pay workflow to allow invoices to close properly.

Complaint: When updating Work Order Statuses, the updated status would sometimes disappear from existing Work Orders that had that status set.

Correction: Fixed.

February 12th, 2025 Release Notes

Learn More at Flyntlok Dealer Management System

Check out our Flyntlok YouTube channel for more highlights of the application!